Metcalf

Expedition Leader

Making progress....

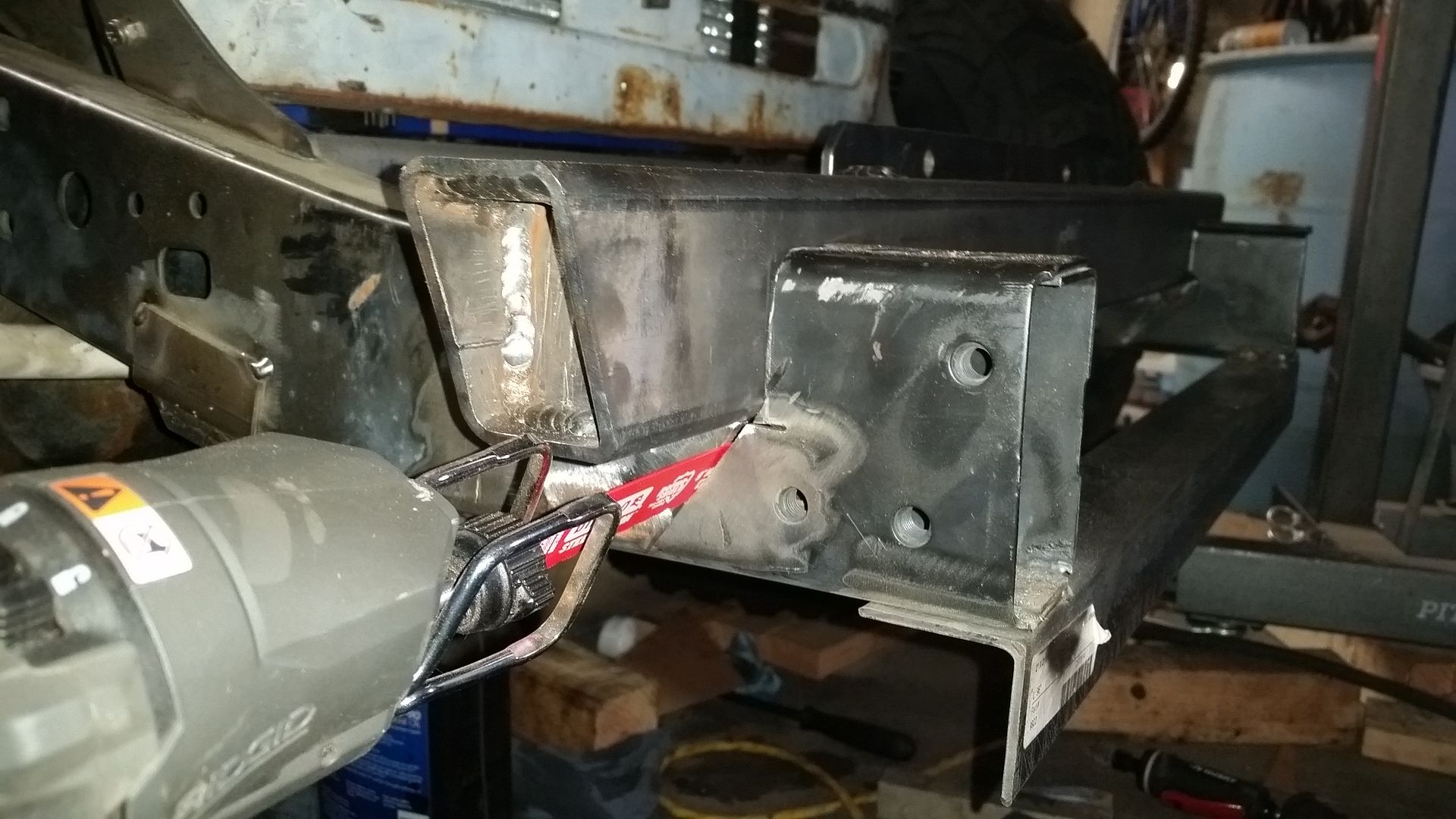

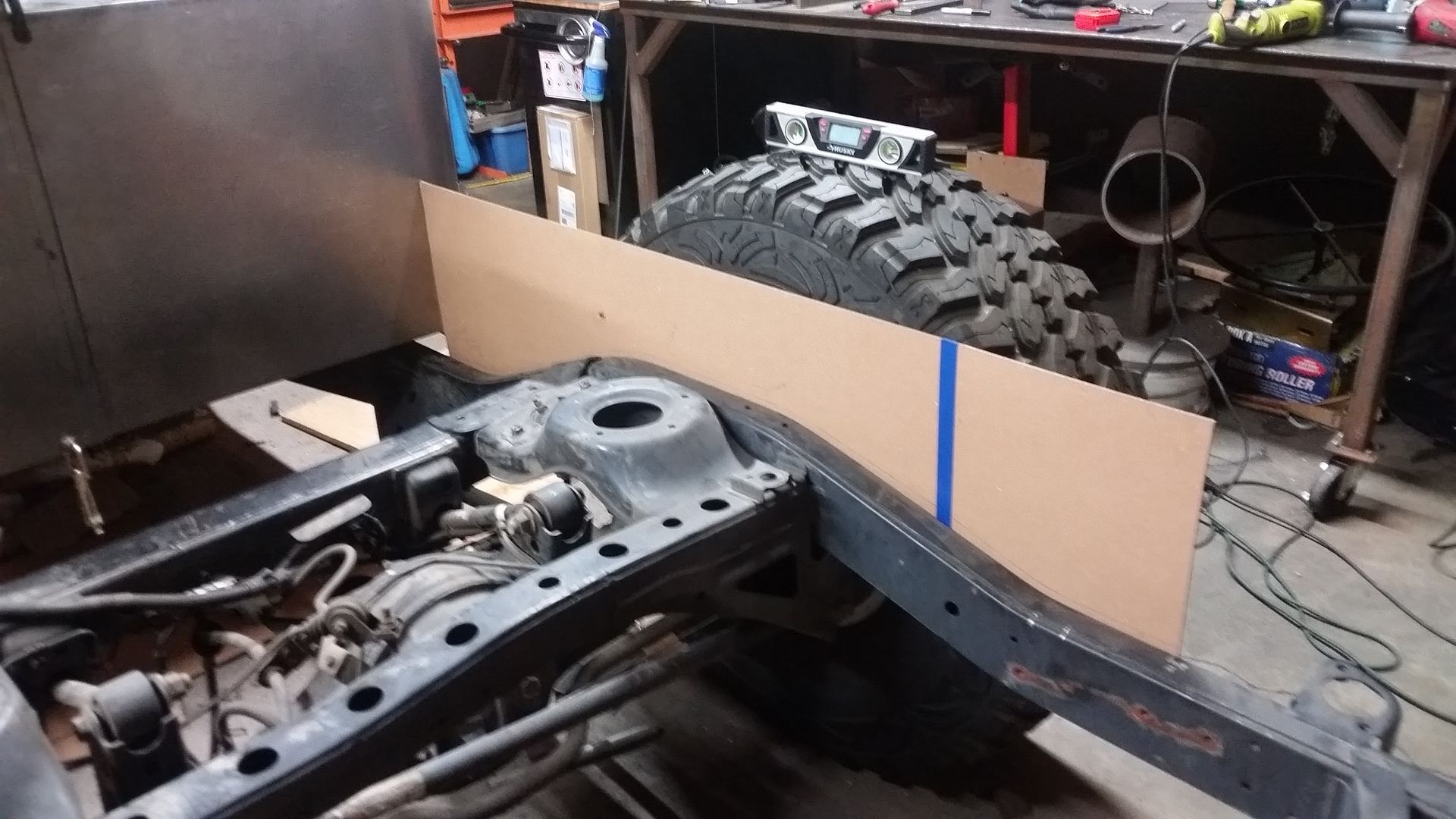

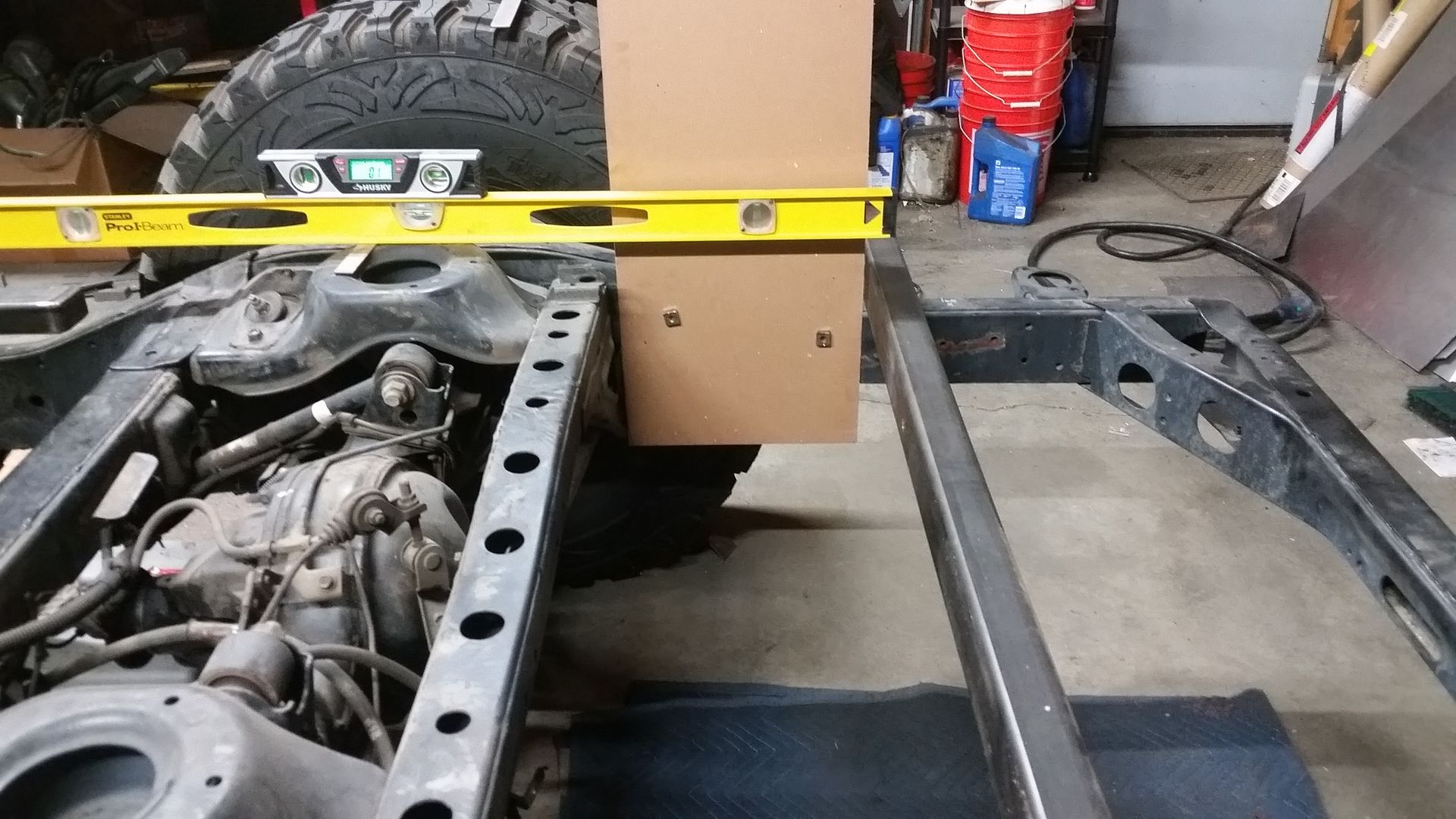

I finished up the frame mount for they assist ram. I plated the frame with 10 gauge around 3 sides. I also tied it into the grill crossmember. I don't think it is going to go anywhere now ever.

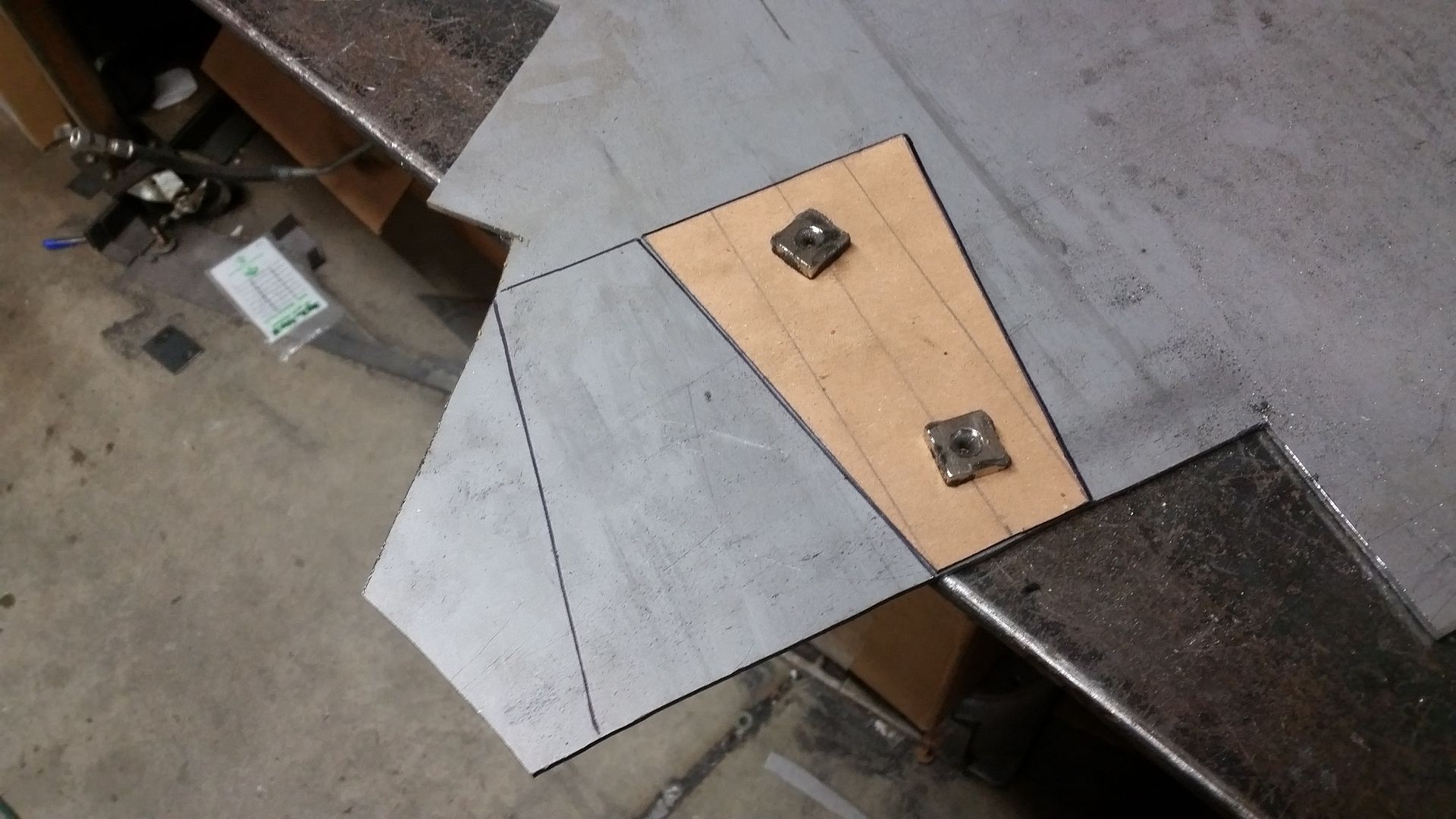

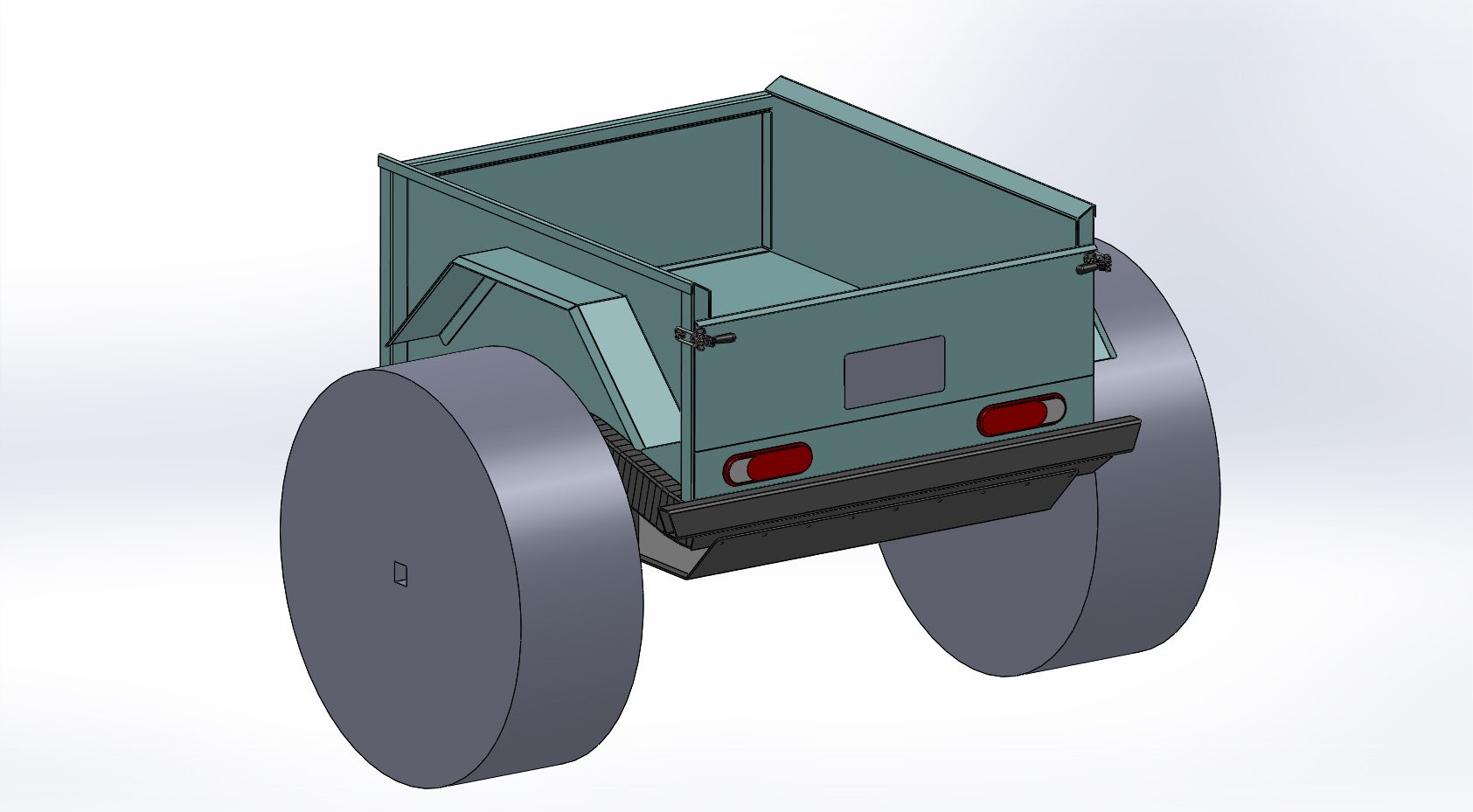

This car is getting something a little bit different for recovery points. I am going to use some JATE rings from a military Land Rover like a Wolf 90/110. One thing I have never liked is D-ring mounts that hang out in front of the bumper....and how they deal with side loads. The thing I really like about these is that the mounts where very simple and clean. The ring folds almost flat against the bumper also. I should be able to pull in a variety of directions. In the out position there is plenty of room to attach a winch hook, hard or soft shackle, or loop a strap. I will be using these on the rear bumper also to make things look uniform.

My funny name for them...

Lip Rings

Some details and tips....

BEST WELDING HELMET MODIFICATION EVER!

Thanks go to DanielBuck for this idea. Now I need to glue it on or something. Maybe some industrial velcro?

Shop tip.

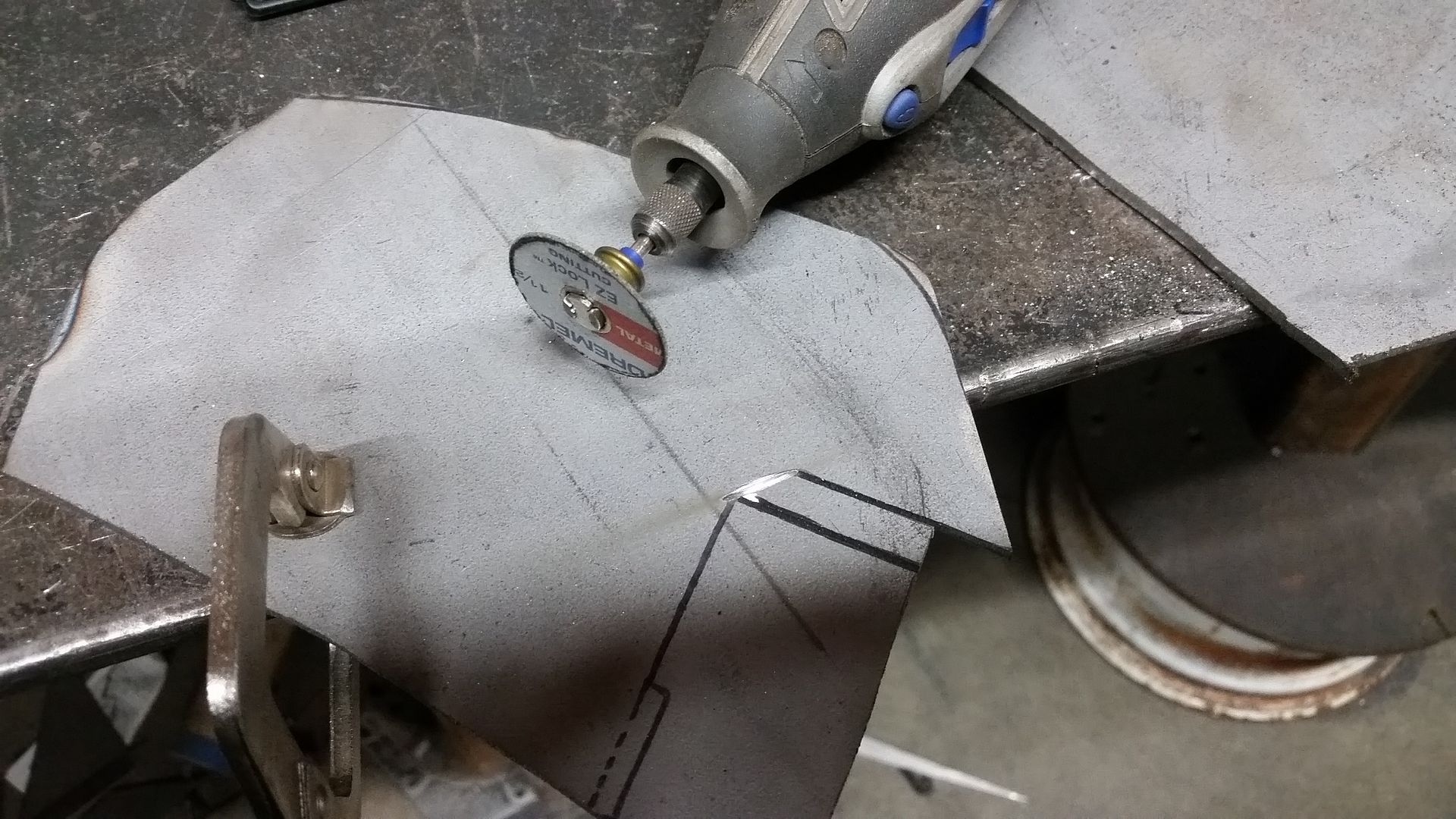

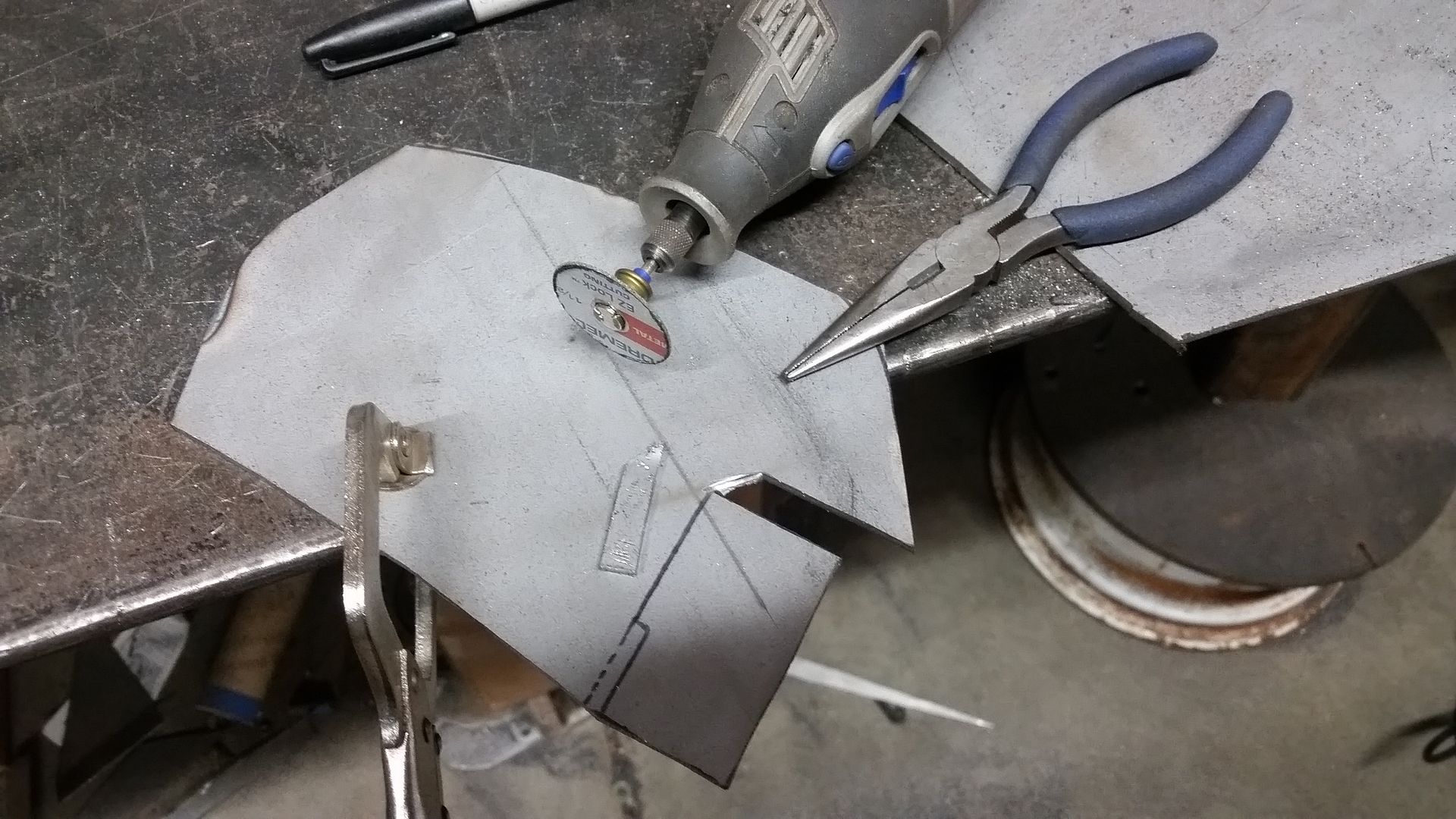

Sometimes when you are using a square on the edge of tubing the radius is taller than the edge. This can make marking the middle of the tube a challenge since it just isn't half of the tube. If you mark from both sides and slowly adjust things you can find the dead center.

Welding around tubing this this kinda sucks, but the helmet light helps a ton!

I finished up the frame mount for they assist ram. I plated the frame with 10 gauge around 3 sides. I also tied it into the grill crossmember. I don't think it is going to go anywhere now ever.

This car is getting something a little bit different for recovery points. I am going to use some JATE rings from a military Land Rover like a Wolf 90/110. One thing I have never liked is D-ring mounts that hang out in front of the bumper....and how they deal with side loads. The thing I really like about these is that the mounts where very simple and clean. The ring folds almost flat against the bumper also. I should be able to pull in a variety of directions. In the out position there is plenty of room to attach a winch hook, hard or soft shackle, or loop a strap. I will be using these on the rear bumper also to make things look uniform.

My funny name for them...

Lip Rings

Some details and tips....

BEST WELDING HELMET MODIFICATION EVER!

Thanks go to DanielBuck for this idea. Now I need to glue it on or something. Maybe some industrial velcro?

Shop tip.

Sometimes when you are using a square on the edge of tubing the radius is taller than the edge. This can make marking the middle of the tube a challenge since it just isn't half of the tube. If you mark from both sides and slowly adjust things you can find the dead center.

Welding around tubing this this kinda sucks, but the helmet light helps a ton!