loren85022

Explorer

I watched the entire screenshow. Definitely a proven suspension. Fun looking group.

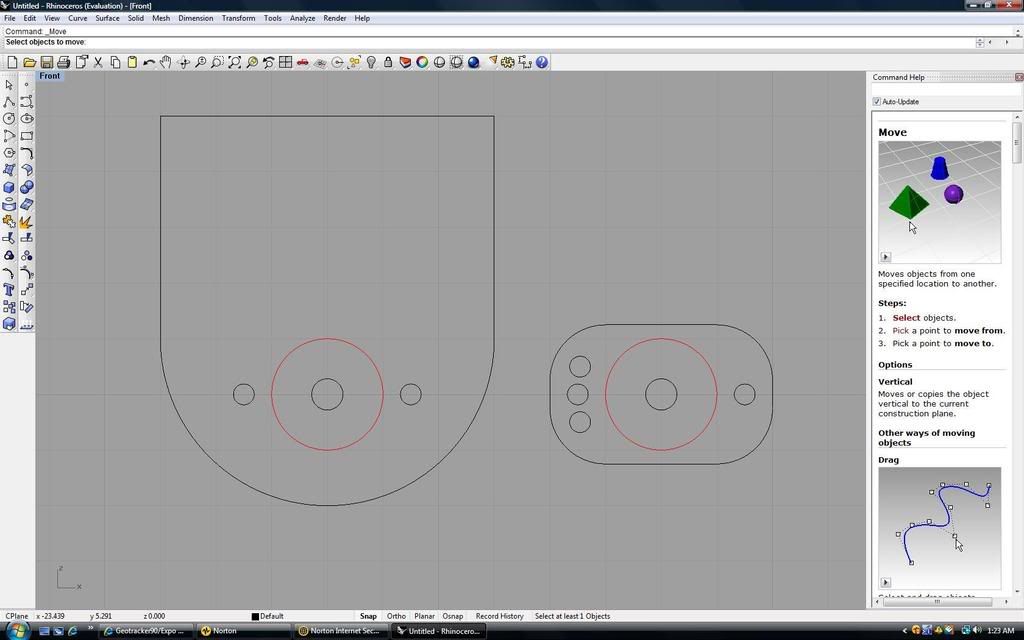

Adjusting for toe should be pretty simple if you added a threaded insert and a bushing with a threaded stud to the inboard side of the trailing arm. Picture of the bushing...

For camber I would have to make the outer trailing arm mounts slotted with a plate to lock in the camber adjustment such as ...

I forgot to show that on the larger bracket, the center bolt hole needs to be slotted. The red circle represents the OD of the bushings. The camber plate is attached to the larger bracket and locked into position with the two outer bolt holes (3/8") as well as the bushing's 9/16" bolt. This set up would be used on both the inner and outer sides of the outer trailing arm bushing.

Confused yet? There would be no gaurentees that this would allow you to get the alignment spot on, but it would help get it pretty close and compensate for any movement of the metal as I welded up the trailing arms.

What do you think?

I think you also have to understand the accuracy of chassis on vehicles.

on the average rangerover chassis they can easily be 3/8" to 1/2" out over the length......especially diagonals...

The rear wheels have no real adjustment because its not important....the front wheels yes as they steer the vehicle.

On a trailer it would make little or no diference if the wheels were miss aligned by 3/8" or more.

Tire wear at that amount would be negligable if not completely unseen....

especially when you consider the amount of miles you'd complete....

I started with a shop bought frame and it was easily 1/2" out on the diagonals

and still tracked fine.

I'm working to about 1/8" tolerance on the frame of my new one.....

The upper body was built matched to the frame.

Movement during welding is normal...and way worse on small wall tubing, the heavier wall you get the less movement you'll have.

And also small tack welds done first....beat the item into shape and then final weld the construction is an easy 'garage method' of getting less movement.

If you just completly weld one side....by the time you turn it over.....its changed shape...wether you clamped it down or not.

Front suspensions and alignment is highly important....and the manufacturers know they can't weld the parts to a sufficient tolarance...hence the in built adjustment in the design.