jscherb

Expedition Leader

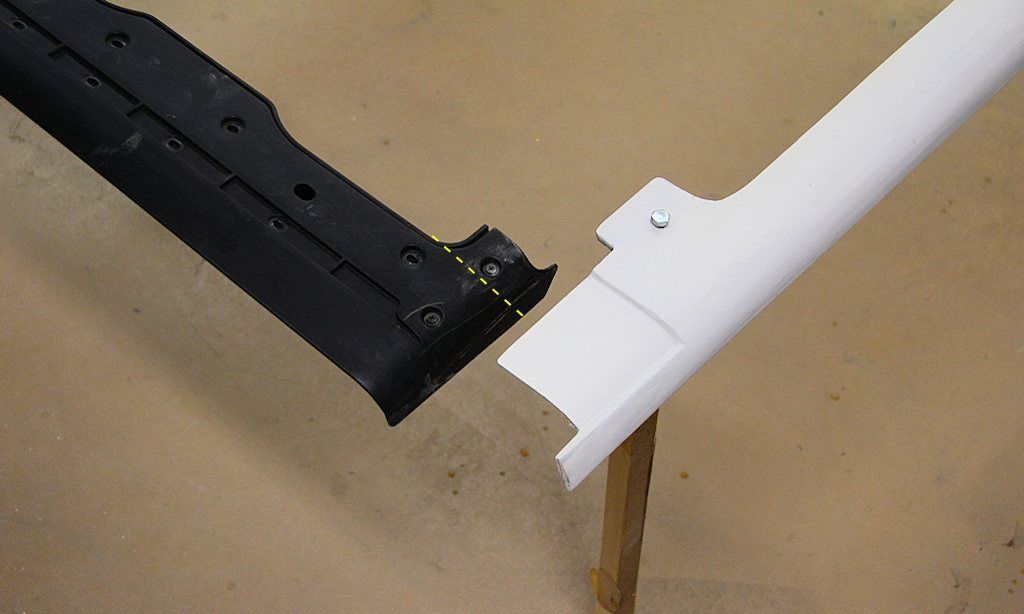

The other day I picked up a complete JKU soft top for $75, including frame (the frame isn't shown in this photo).

I bought it for several reasons:

- I'll sew the Safari Cab soft sides using the fabric from the roof panel.

- I can turn the back window into the Safari Cab soft barn door.

- I'll use the header for my Safari Cab soft roof concept (there's no header in the photo below).

I don't have a use for the side windows with the Safari Cab, but maybe I'll come up with something creative to make from them. A couple of ideas...

- I could use the extra fabric from the roof panel and replace the windows (which are scratched anyway) with fabric to make solid side panels with no windows for the factory soft top.

- I could make roll-up sides for the factory soft top using the parts - the factory sides don't roll up because of the plastic edge in the front and on the bottom; I could modify these so they could roll up. That way they could be opened up on the road without worrying about storing them, you'd just roll them up and leave them attached.

- I could try installing one of the half door slider windows in them, I think the rear door sliders would probably fit.

Any other ideas?

I bought it for several reasons:

- I'll sew the Safari Cab soft sides using the fabric from the roof panel.

- I can turn the back window into the Safari Cab soft barn door.

- I'll use the header for my Safari Cab soft roof concept (there's no header in the photo below).

I don't have a use for the side windows with the Safari Cab, but maybe I'll come up with something creative to make from them. A couple of ideas...

- I could use the extra fabric from the roof panel and replace the windows (which are scratched anyway) with fabric to make solid side panels with no windows for the factory soft top.

- I could make roll-up sides for the factory soft top using the parts - the factory sides don't roll up because of the plastic edge in the front and on the bottom; I could modify these so they could roll up. That way they could be opened up on the road without worrying about storing them, you'd just roll them up and leave them attached.

- I could try installing one of the half door slider windows in them, I think the rear door sliders would probably fit.

Any other ideas?