DeLorme InReach Explorer mount and power supply

INSTALLATION

Now that all the parts and tools are in order, I was ready to start.

I began by cutting off the 12v adapter plug from the Powered inVehicle RAM Mount. I stripped back insulation to expose the individual wires. Although there are four pins on the cradle that connect to the back of the InReach Explorer, only the two outside pins are in use.

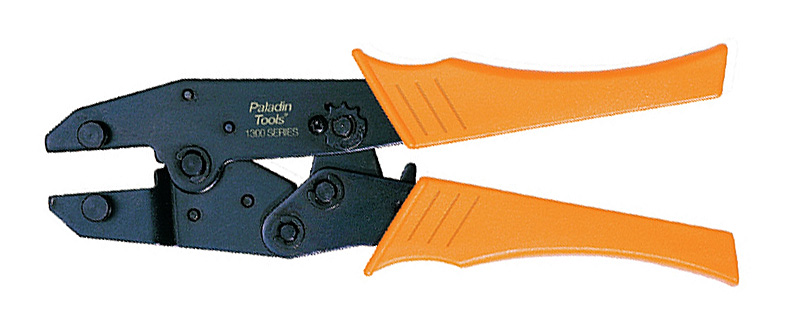

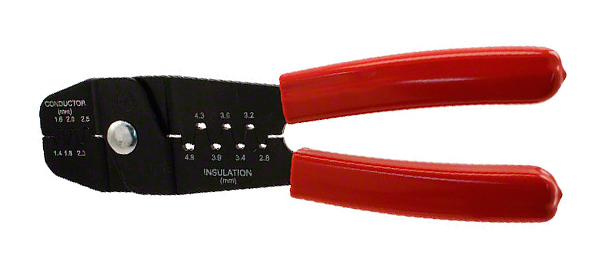

Next, I cut a red and black 18AWG wire a few inches long. All wires were stripped and crimped to the RAM mount wiring using 18AWG butt splices. In hindsight, I probably should have just left the wiring longer from the cradle and omit the but splices altogether. Then I could have simply crimped on the Molex terminals and be done with it. Oh well!

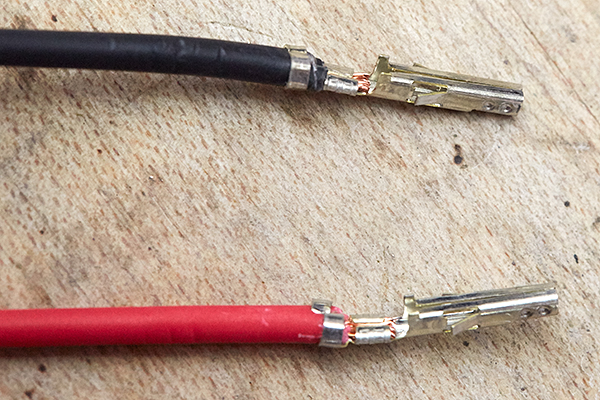

On the opposing end, I stripped and crimped on Molex female Mini-Fit Jr. terminals.

I cut a piece of 1/2" heat shrink tubing, slid over the two wires and butt splices, and used a heat gun to shrink in place.

I inserted the terminals into the female receptacle connector.

As you can see, I kept these wires very short. This was intentional so that I could remove the entire mount in the future if need be.

Next, I removed the A-pillar cover. The mounting bolt covers can be removed with your fingernail or a small screwdriver.

After removing the two mounting bolts, the A-pillar trim cover was removed by simply pulling it away from the pillar.

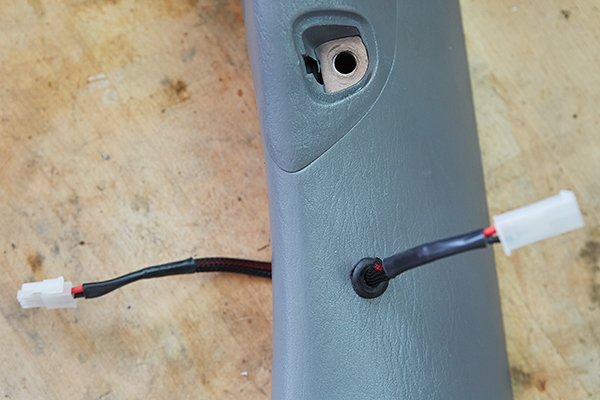

Next, I drilled a 3/8" hole into my A-Piller cover just below the lower handle bolt and pushed in the rubber grommet.

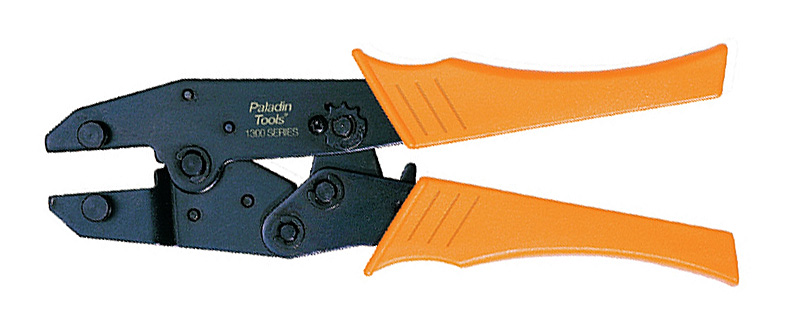

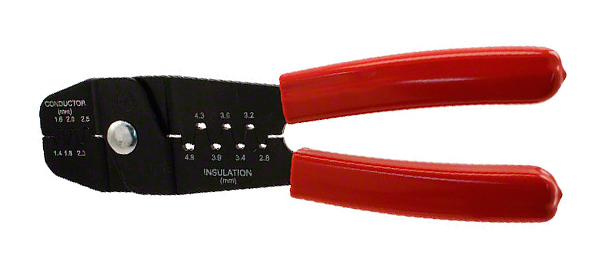

I needed to make another length of wire that traveled through the A-pillar trim. This was about 12" long with Molex connectors on either side. This way, the entire trim piece can be removed. The process involved installing a connector on one end and then covering the wires with braided sleeving and heat shrink. I inserted the wire harness through the rubber grommet before installing the terminals and connector on the opposing end.

From the backside, you can see where the hole was made in approximation to the mounting hole.

After this, I made the power supply wiring harness. I cut several feet of wire and installed Molex terminals and connectors to both ends. As before, I used braided sleeving and heat shrink to protect the wiring and group them together.

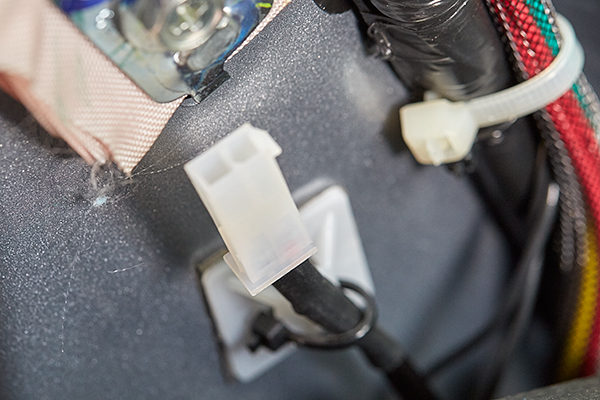

I routed the wiring harness up through the dash and secured it in place at the bottom of the A-pillar with a cable tie mount and zip-tie. I kept the zip-tie loose, which was intentional so that the wiring could be maneuvered as required. This made installation and removal of the A-pillar trim easier. (By the way, an electricians fish-tape or coat hanger aids in navigating the wire up behind the dash and to the A-pillar.)

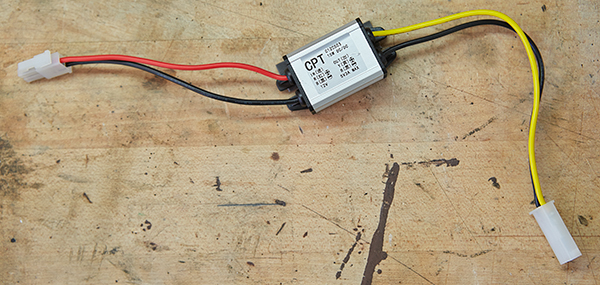

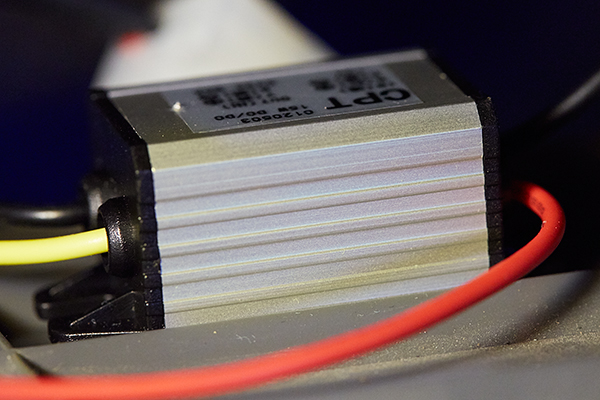

I installed Molex connectors to both the input and ouput sides of the 12v-to-5v converter.

The converter was mounted with 3m double-sided tape to the backside of the under-dash trim panel. The output of the converter connects to the wiring harness routed up behind the dash and to the A-pillar.

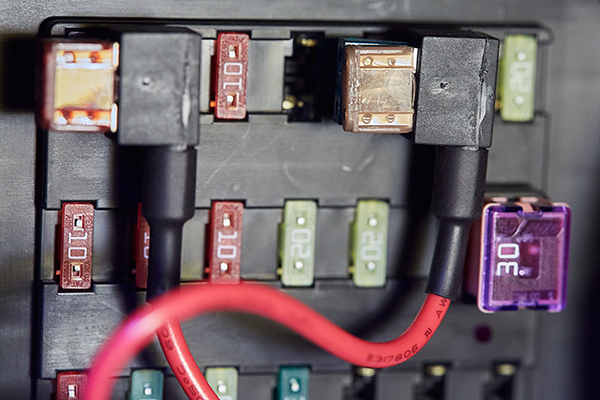

To connect the input side of the converter to power and ground, I made another wiring harness. A Molex connector was installed on one end with both wires. For the opposing ends, the red wire connected to a fuse-tap for power, and the black wire terminated with a ring terminal for ground.

The 12v-to-5v converter was attached to the backside of the trim piece below the steering column. Ground was terminated at a mounting bolt. This wasn't an ideal spot for grounding, but will suffice for the time being. I ultimately plan to install an additional fuse block within the cab.

For the 12v source, I used a fuse tap.

To re-install the A-pillar trim, I needed to do a little fabrication. I first bored the hole in the zinc spacer from 1/4" to 5/16". Then I cut a length of aluminum tubing so that it spanned the length of the shaft in the RAM ball mount and the spacer.

When put together, it looked like this.

The A-pillar trim was re-installed by first connecting the wiring together with the Molex connectors

After securing the top bolt, I used the RAM ball mount with spacer for the bottom mounting hole.

The cradle was mounted using a short double socket arm, RAP-B-201U-A, and positioned in place.

Using a volt meter, I tested that I correctly had 5 volts on the two outside pins.

With the DeLorme InReach Explorer in place, the GPS unit received power whenever the ignition was on.

Success! I now had a secure mount for my DeLorme InReach Explorer with a dedicated power supply. I was very happy with the results.