chet6.7

Explorer

My truck was built in the time period of the recall.

I checked the welds,there are no visible cracks. From what I remember from the thread on CF,I believe there is supposed to be a more coming from FCA on Oct. 9.

08/26/2015

New Safety Recall Advanced Communication – R46082615

FCA US LLC announced a safety recall on certain 2013 and 2014 model year (DJ / D2 / DD) RAM Trucks.

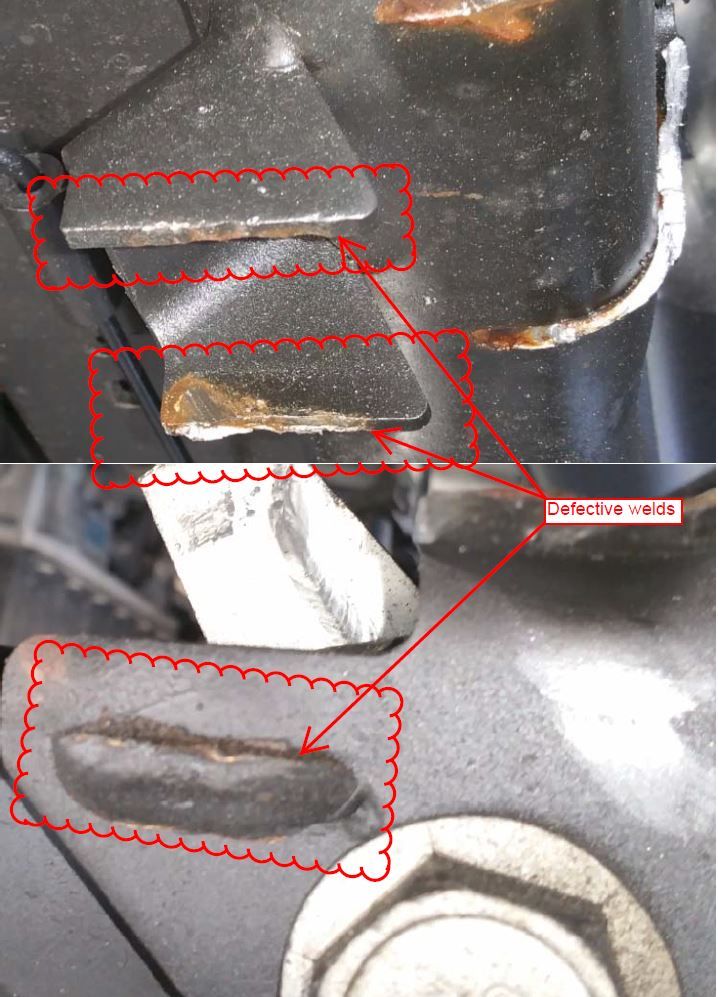

Some of the above vehicles may have a front suspension track bar frame bracket that was improperly welded during the manufacturing process. The front suspension track bar frame bracket welds may break and allow the front suspension track bar frame bracket to separate from the frame rail. A separated front suspension track bar frame bracket will cause diminished steering response and could cause a crash without warning under certain driving conditions.

FCA will conduct a voluntary safety recall on all involved vehicles to inspect the front suspension track bar frame bracket.

 For vehicles without a separated front suspension track bar frame bracket and/or cracked weld(s), additional support brackets must be installed.

 For vehicles with a separated front suspension track bar frame bracket and/or cracked weld(s), a new front suspension track bar frame bracket must be welded to the frame.

Dealers will be notified of the launch of this safety recall by way of established methods used in the past.

We ask that you please take the time to ensure that your personnel are aware of this communication and are prepared to execute a customer friendly process for inquiries on involved vehicles.

Customer Services Field Operations FCA US LLC

Recall R46 / NHTSA Campaign Number: 15V-541

http://www-odi.nhtsa.dot.gov/owners...eria.make=RAM&searchCriteria.prod_ids=1973413

I checked the welds,there are no visible cracks. From what I remember from the thread on CF,I believe there is supposed to be a more coming from FCA on Oct. 9.

08/26/2015

New Safety Recall Advanced Communication – R46082615

FCA US LLC announced a safety recall on certain 2013 and 2014 model year (DJ / D2 / DD) RAM Trucks.

Some of the above vehicles may have a front suspension track bar frame bracket that was improperly welded during the manufacturing process. The front suspension track bar frame bracket welds may break and allow the front suspension track bar frame bracket to separate from the frame rail. A separated front suspension track bar frame bracket will cause diminished steering response and could cause a crash without warning under certain driving conditions.

FCA will conduct a voluntary safety recall on all involved vehicles to inspect the front suspension track bar frame bracket.

 For vehicles without a separated front suspension track bar frame bracket and/or cracked weld(s), additional support brackets must be installed.

 For vehicles with a separated front suspension track bar frame bracket and/or cracked weld(s), a new front suspension track bar frame bracket must be welded to the frame.

Dealers will be notified of the launch of this safety recall by way of established methods used in the past.

We ask that you please take the time to ensure that your personnel are aware of this communication and are prepared to execute a customer friendly process for inquiries on involved vehicles.

Customer Services Field Operations FCA US LLC

Recall R46 / NHTSA Campaign Number: 15V-541

http://www-odi.nhtsa.dot.gov/owners...eria.make=RAM&searchCriteria.prod_ids=1973413

Last edited: