Open sesame! The door to the world

So far the most difficult part of our build project has been the door. We spent many hours talking to caravan manufactures trying to get a door that looked the business and was constructed well enough to match the general construction of our 6x6.

We even discussed having a door built by some of the yacht builders, most of the problem were that the construction material was limited and that just about all had single point latches.

Our preference was for double point if not triple point latching and sturdy construction. We felt if any one tried to break into our truck living area it would be through the door. We had purposely made long skinny windows high up or small windows so that they offered limited access. So we wanted a door that would deter people. Basically we want someone else to be easier to break into than us knowing full well that determination will concur engineering every time, but if we are harder than next door, well easy is best when breaking in I guess.

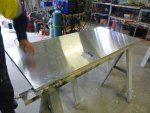

The options that we had came down to build it our self. Thankfully my step father is a master craftsman and made it for us. Whilst it was not simple he did make it look easy. All I can say is thanks mate you are truly skilled.

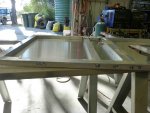

We used a recessed handle so as not to have a major component that could be dragged off in the bush, now whilst this may mean that some knob could push it back whilst we are in it, we positioned a decent size window so you can reach out and open it just in case of knobs. Well also so you can see what you are opening the door onto, have to be careful in case the zombie apocalypse actually happens.

The locking mechanism is double acting both top and bottom. The window opens so that the seam facing the front of the vehicle is the hinge point. It is made of high impact resistant plastic and is held in place by a number of screws.

The door has 3 hinges that are pop riveted on, the rivets had to be turned down on the lath so as to fit the hinge recess. The rivets themselves are so large that we had to purchase a special gun to put them in, as the air rivet gun wouldn’t do them. Actually inserting the top rivets saw me struggling so much with the hand rivet gun to pop them off that I fell off the ladder. Thankfully all those years of martial arts came in handy and it was a good fall.

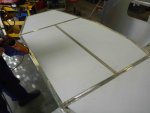

So the door is made of 1.6 mm Al with a lot of inner frame work. It is lined with the 25 mm poly and 1.6 mm Al inner skin. It has a 2 point locking system it fits perfectly and we are yet to fit the door seal but that will be added when it’s time to do the finishing touches.

to be continued as time and adult supervision allows

regards

Carts from WA

..

..