ntsqd is correct about the two types of ferrules. I could have been more descriptive and thorough there.

I also wasn't very good at defining the types of connections you will find either. I mixed two different things in that section: a) how the hose/tube/pipe is interfaced to the connector and b) the connector type itself.

For any gas/LP line you will have two things you are dealing with:

1) the tube/pipe/hose itself

2) the connections between tube/pipe/hose and the components of the system

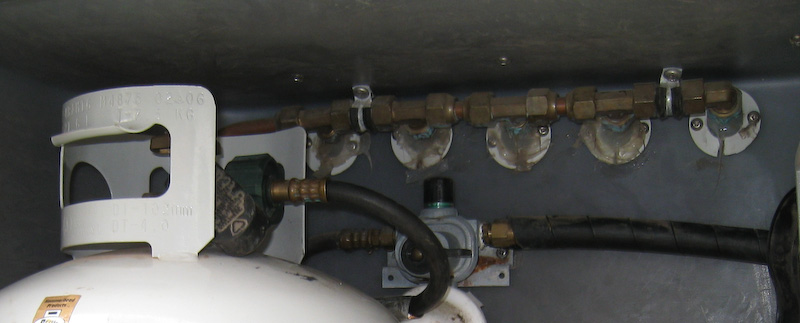

The components of a propane/LP system are typically:

1. Propane/LP tank(s)

2. Tank selection valve

3. Regulator (establishes a consistent line pressure that matches what the appliances expect to see)

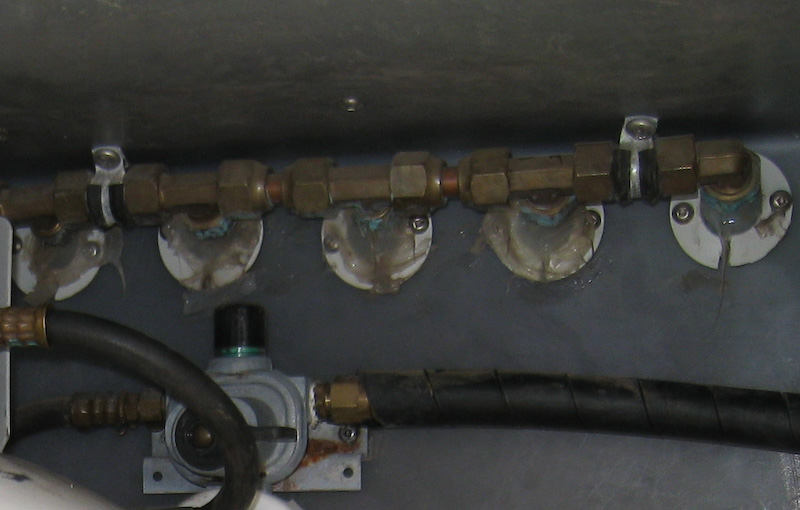

4. Distribution manifold (typically a string of T connectors)

5. Connectors

6. Tube/pipe/hose

7. Appliances

The tube/pipe/hose can be rigid pipe, flexible/malleable tubing (copper or plastic – I wouldn’t recommend plastic), or hose (plastic, rubber or a synthetic rubber type material).

At the point the tube/pipe/hose interfaces with the connector you will usually see these types of interfaces:

1. Solder (rigid copper pipe)

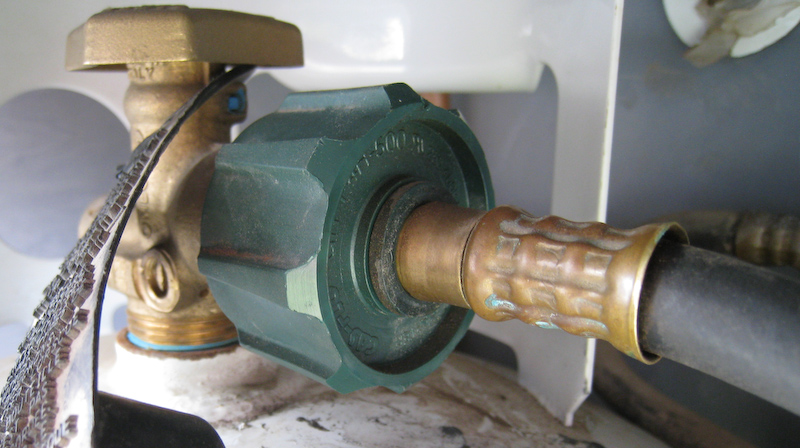

2. Hose barb and external ferrule (illustrated in the photo)

3. Hose barb and hose clamp (illustrated in the jumper photo of the leaking connection)

4. Compression fitting with an integrated internal ferrule (the ferrule slides over the outer surface of the tube/pipe/hose like a collar and is cinched down by the threaded fitting that tightens over the tube/barb onto the connector the tube/pipe is mating up to).

5. Flare fitting with a flared tube/pipe (the flare is held in place by a threaded collar that slides over the tube/pipe and tightens down onto the connector the tube/pipe is mating up to. Together they form a type of compression fitting.

At this point you have a tube/pipe/hose with a connector on the end of it.

The type of connector can be:

A. Solder (rigid copper pipe)

B. Thread (used with any type of tube/pipe/hose) (use propane/LP rated thread compound on this type of connection)

C. Flare (used with malleable soft copper tubing) ( do NOT use joint compound on this type of connection)

D. Compression (technically can be used with any type of tube/pipe/hose, but I’ve never seen it used on rigid copper) (do NOT use joint compound on this type on this type of connection)

You will not be using rigid copper pipe, so we won’t worry about solder.

It is very important to make certain that you have matching connectors for each connection in your system. You must use thread to thread, flare to flare, compression to compression, etc. If you don’t, you can easily have a leak, which is not a good day with a propane/LP system.

You can see an assortment of compression fittings, internal ferrules, etc. here:

http://www.plumbingsupply.com/compress.html

You can see an assortment of barbed fittings here:

http://www.plumbingsupply.com/barb.html

You can see an assortment of flare fittings here:

http://www.plumbingsupply.com/flarefittings.html

You can see an assortment of thread fittings here:

http://www.plumbingsupply.com/brass.html

Make sure to use all brass connectors. Do not use plastic connectors for any portion of an propane/LP system.

Typically, the fixed components such as the regulator, the tank selection valve, etc. will all use female thread connectors. From those points, you will insert connectors of your choice, i.e. flare, compression or thread.

If you use malleable copper tubing for your main appliance distribution, those connectors will probably be flare. At the final connection between the feeder line and the appliance it is common to have a short section of hose to allow for appliance vibration, movement, inspection, etc. The appliance will probably have a female ¼” or 3/8” thread connection, or already have a compression or flare connector inserted.

If you have custom hoses made up you can have the type of connector you require put on each end of the hose.

If you need to pass through a wall/surface/bulkhead use a brass bulkhead connector. You can see a photo of a brass bulkhead fitting here:

http://www.brascomponents.com/bulkhead.htm

It helps tremendously if you standardize on one size of hose/tube/pipe and connectors for your entire system. For a camper size system 3/8” tube/hose should provide adequate flow for typical use of your systems.

If you have any component that has a non 3/8” connector, i.e. a stovetop or water heater, use a brass adapter fitting to convert immediately and directly to 3/8”. This allows you to carry one size of repair hose/tubing and an assortment of only one size of replacement/repair fittings.

It also helps a lot if you standardize on one main type of connector, i.e. compression, flare or thread. That allows you to carry one type of connector for repair/replacement.

All of this probably sounds a lot more complex than it actually is. While it is easy to mix up the types of connectors, especially flare and compression, if you standardize on one type, you can put a system together easily.

As already mentioned, the operating pressure of a propane/LP system downstream of the regulator is very low. This helps limit leaks.

Take your time, be meticulous and use a spray bottle with soapy water to test your system during and after your build and you’ll be fine. Check it every few weeks in your first few months on the road after things have shaken around a little bit.

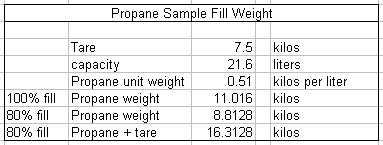

The connector on the output of the propane/LP tank valve will vary by country and tank size. You will use a U.S.A. small ACME (right hand 1 3/8” thread) on your system while in the U.S. It is the only legal connector in the U.S.A. for consumer propane/LP tanks. POL (left hand 7/8” thread) is probably the most common in the Americas outside the U.S. and Chile. If possible, before you leave secure a few male POL to 3/8” barb connectors from a propane supply house similar to those in the lower left corner of this data page:

http://www.victormfg.com/PDF/LP Gas Catalog Pages/p108.pdf

Make sure you have the brass parts necessary to create a new tank feeder hose from a POL thread tank valve to your tank selection valve, if you have one, or your regulator. Don’t forget stainless steel radiator clamps of the necessary size. Typically, the tank feeder hose would include a brass POL male to 3/8” hose barb connector (this end goes into the tank valve), some propane/LP rated 3/8” hose, and a brass barb to 3/8” or ¼” male thread connector (this end goes into the valve or regulator).