Tonight's update....

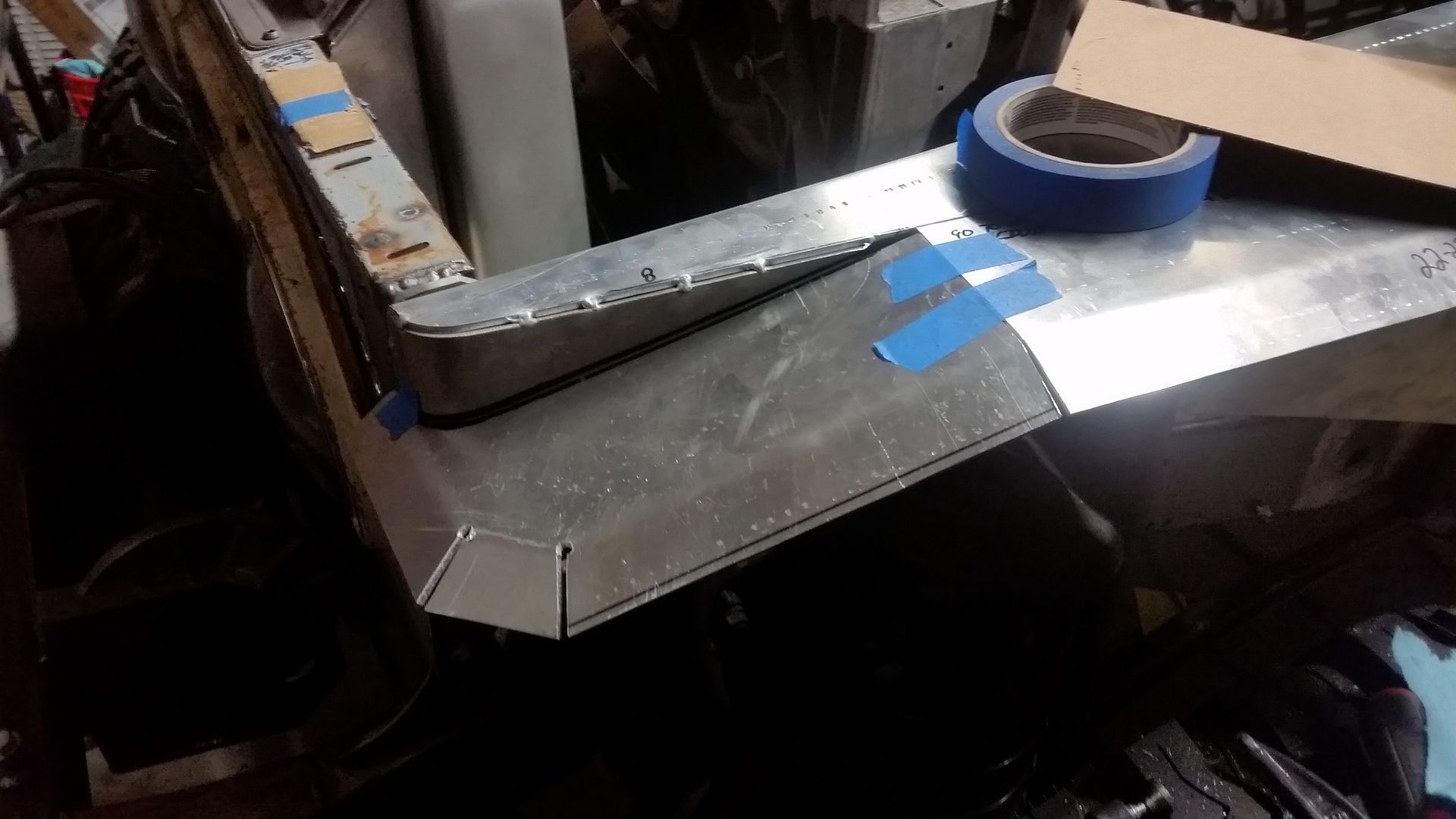

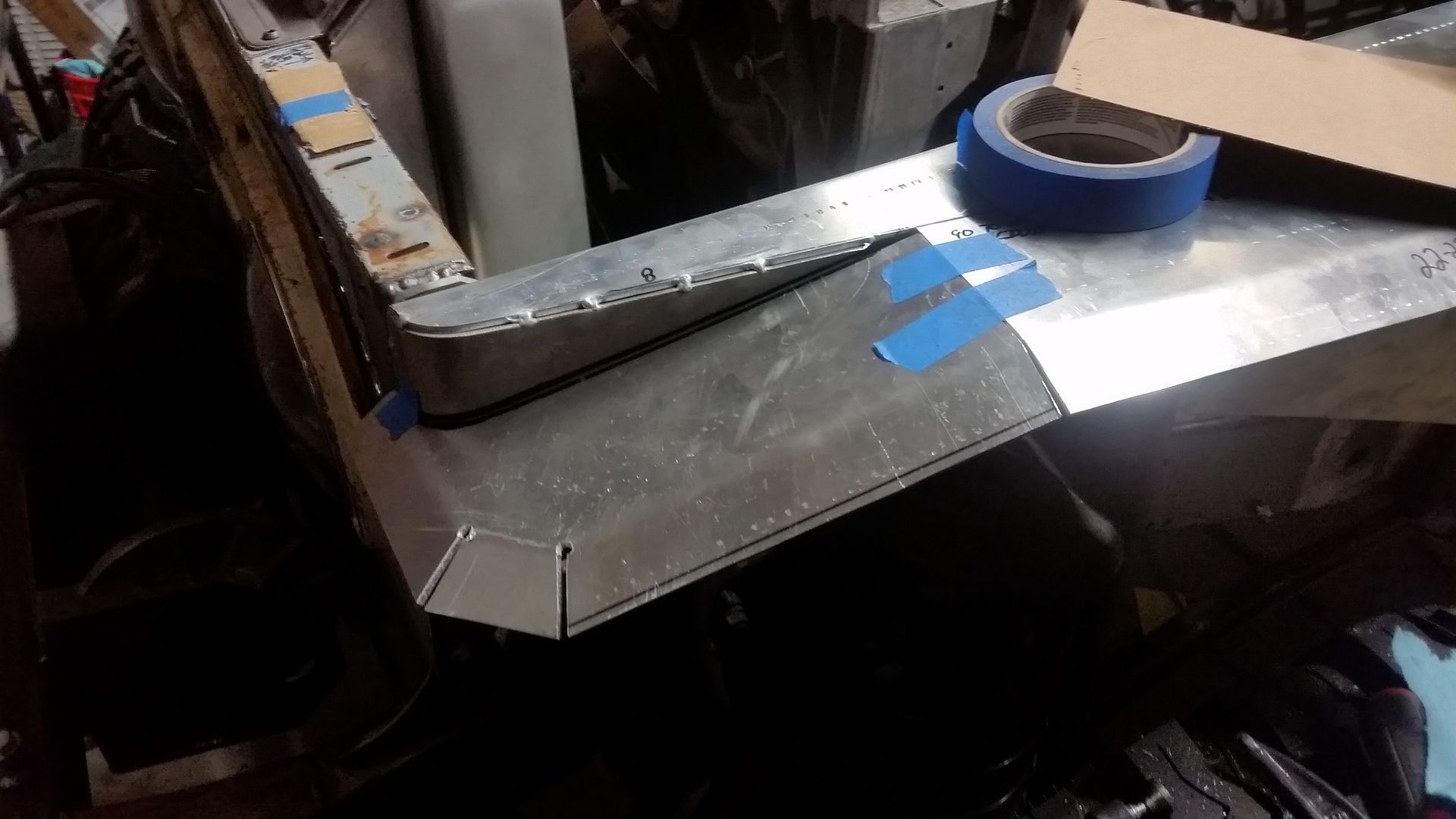

I made the last big part for the drivers front fender. Overall I am really happy with how it turned out so far. Now I just need to glue it all together and dress all the visible welds down.

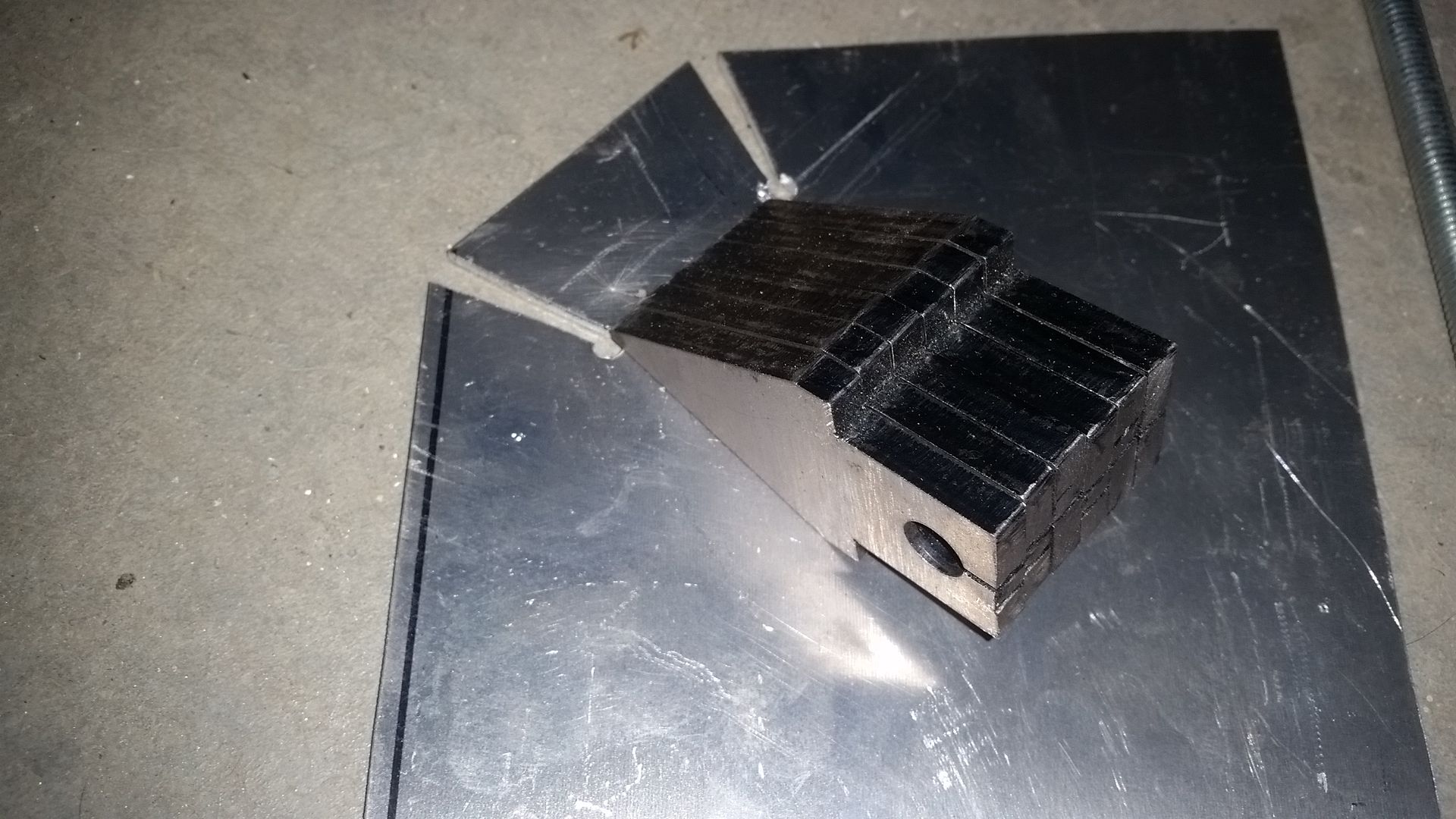

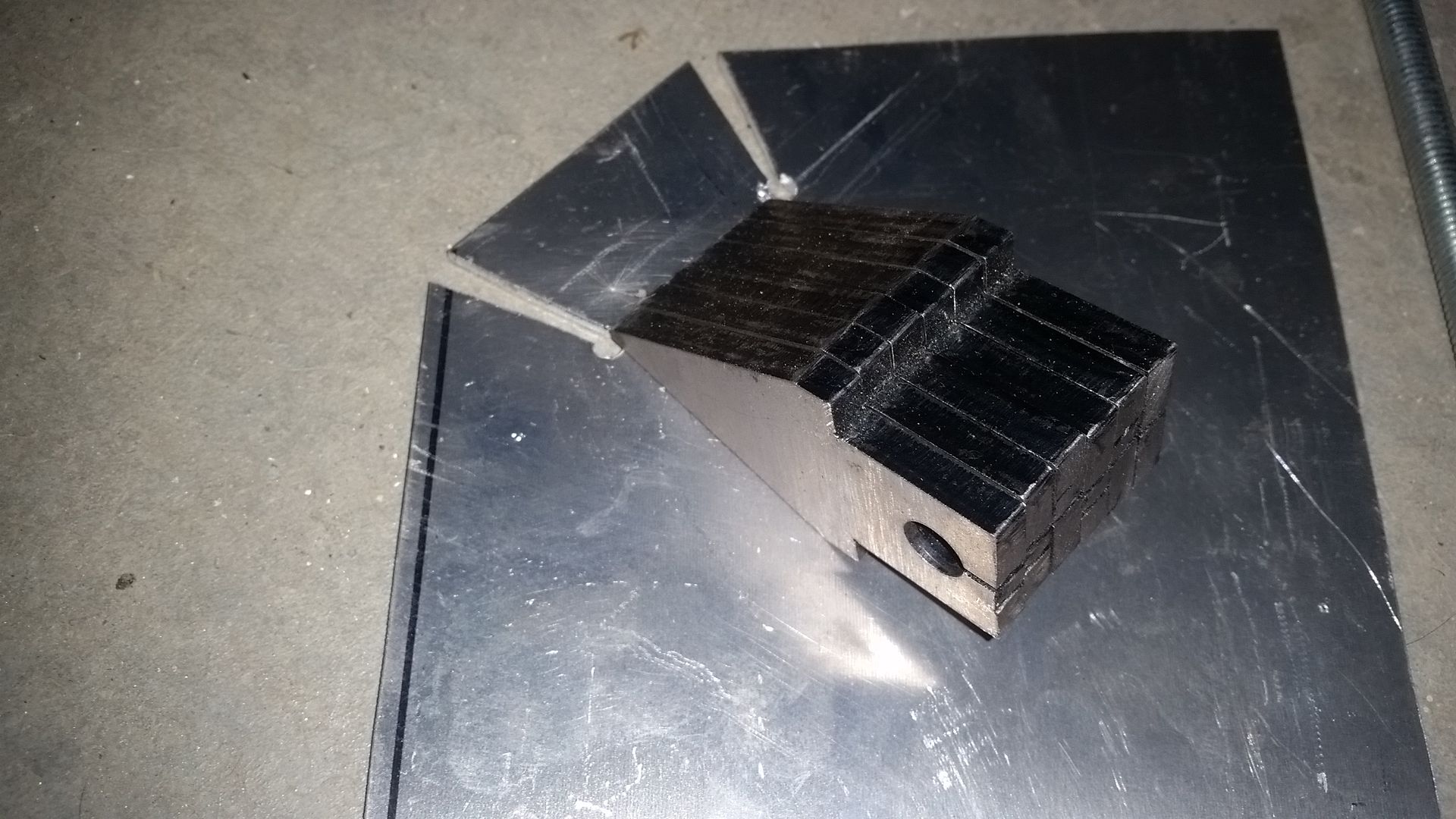

I was able to fold this forward 'bill' in one part using my homemade press brake with the laminated tooling. The 1/4" wide tools let me dial in the bend width. I am also make new tooling pretty easy if I have more crazy ideas in the future.

The part got root clearance holes at the corners. I saw cut the clearance for the multiple tabs to fold together.

Not the best shot, but I also have a laminated bottom die. This lets me run the part off the end so the next tab didn't get in the way.

Here is the top die reset to the correct width for the final bend. It was basically done to match the other two folds. The machine also has a way to have a bend stop, but I haven't got that dialed in completely yet. I just usually bend with a small test part to match the angle.

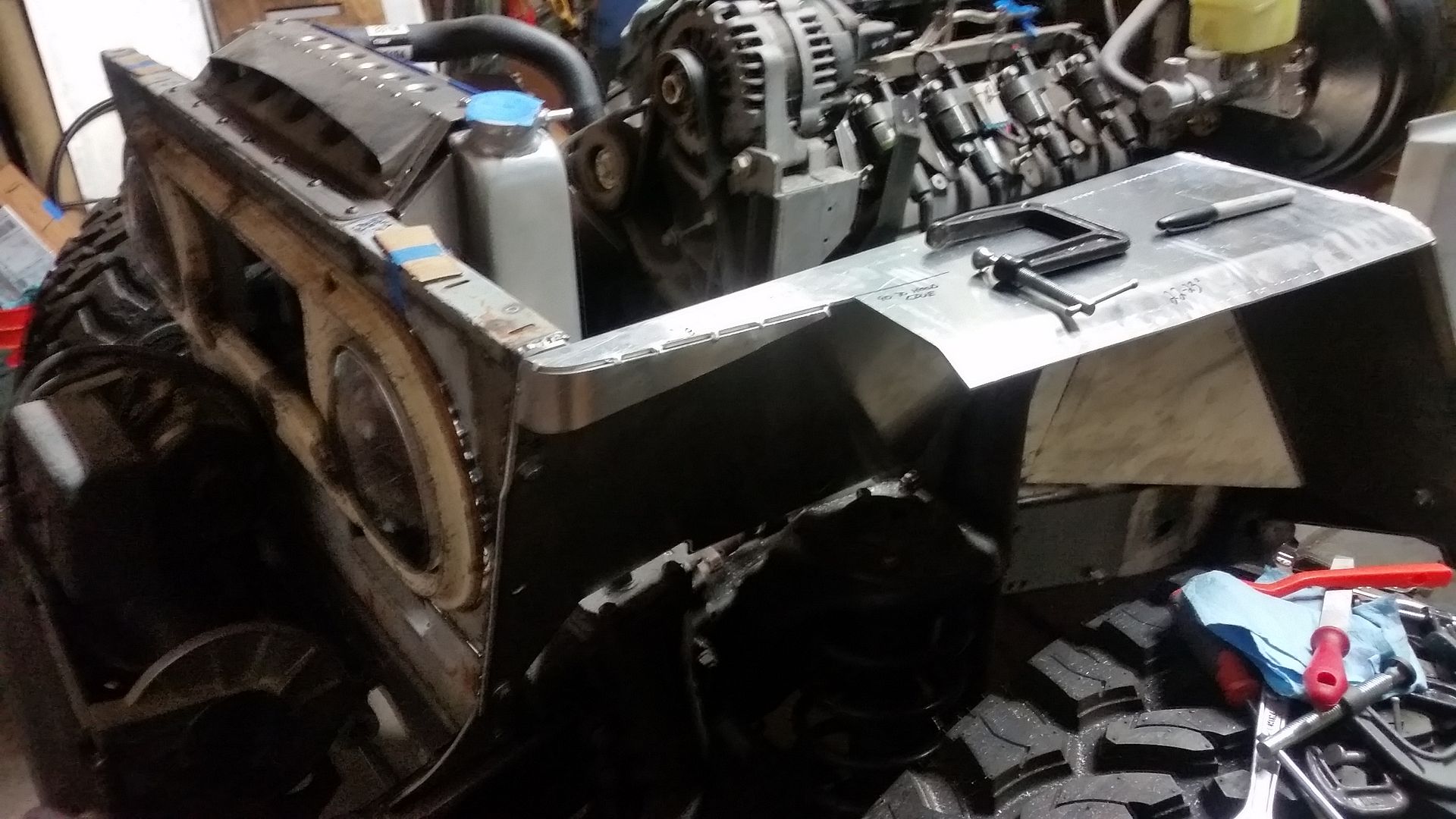

Fitting the 'bill' in place. Overall pretty happy! I will be able to weld a lot of the back seams also.

I do have to add one more little part here. It will just be a little triangle. I could have added it to the 4th part, the 'bill', but I just decided to weld it in later. I am going to pay with a few designs for that last triangle by changing the leg length on the grill side.....

Now to weld it all up, dress down the visible seams, and then start on the other side....