Next mini-project.....fan shroud

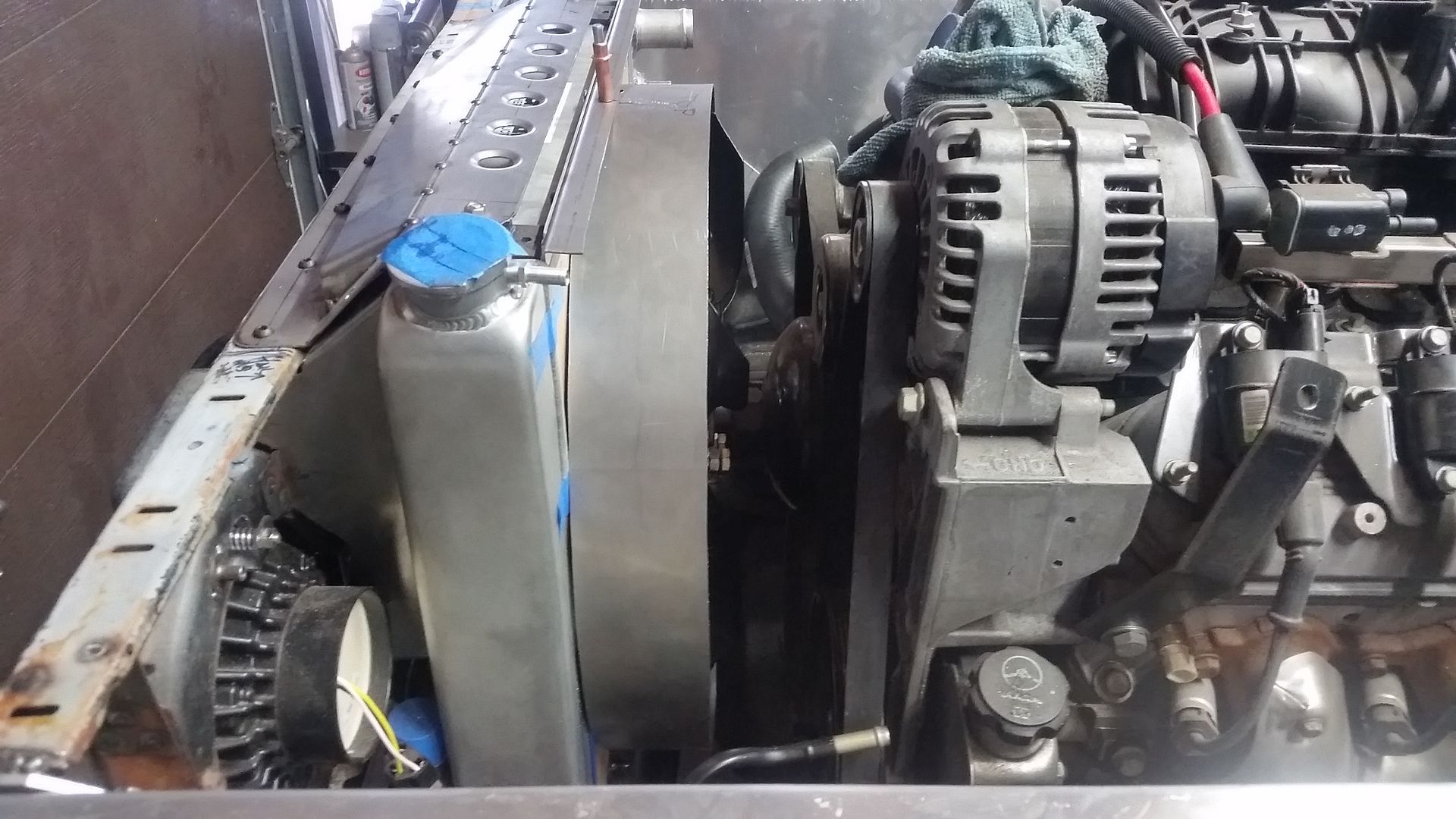

I was able to transfer the rough outline of the fan to the chip board fin protector while it was in the vehicle.

The shroud is going to be 16 gauge steel I think. I have some of it laying around. It is a little overkill probably, but there really isn't going to be much material in this when it is all trimmed out.

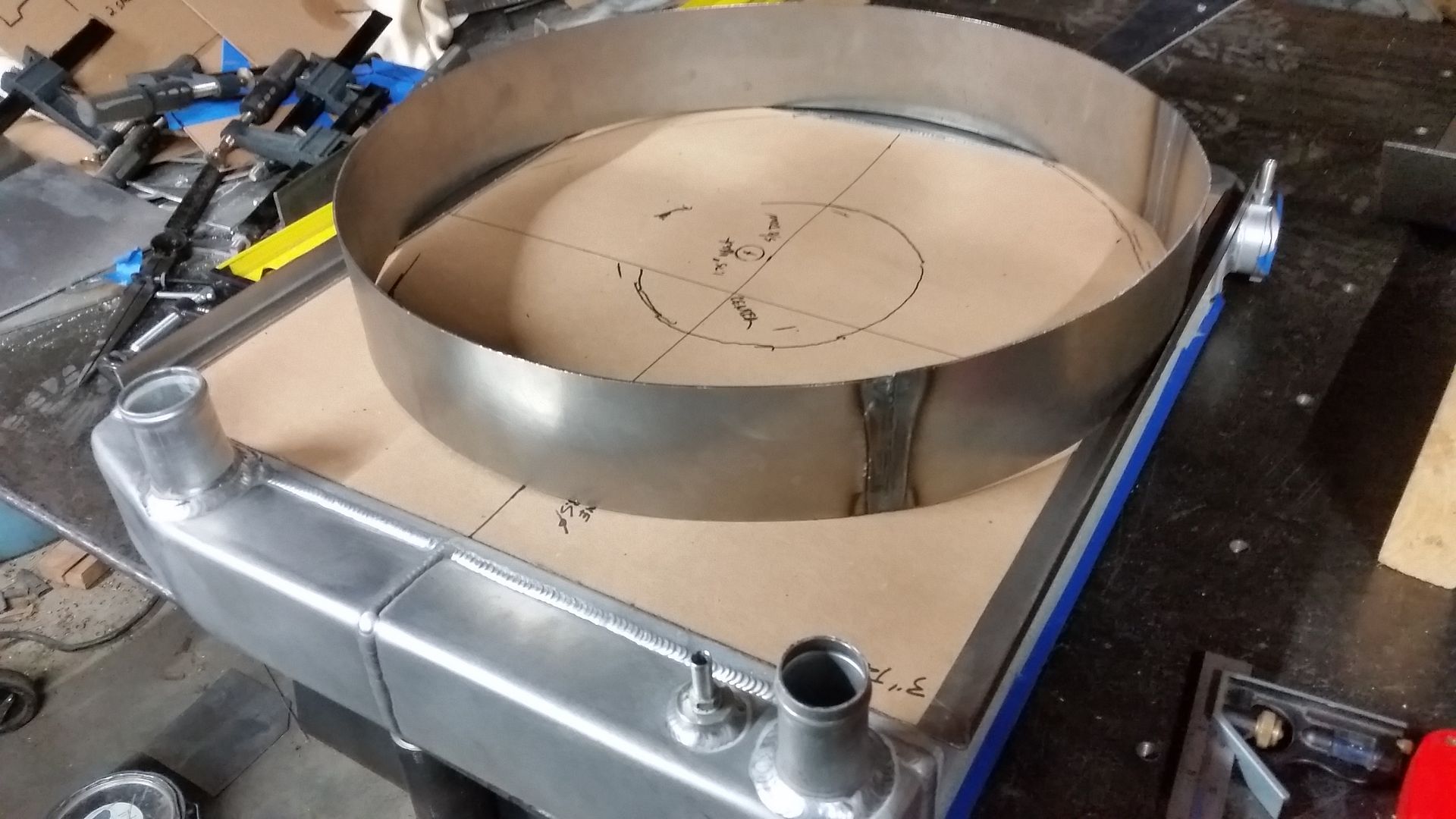

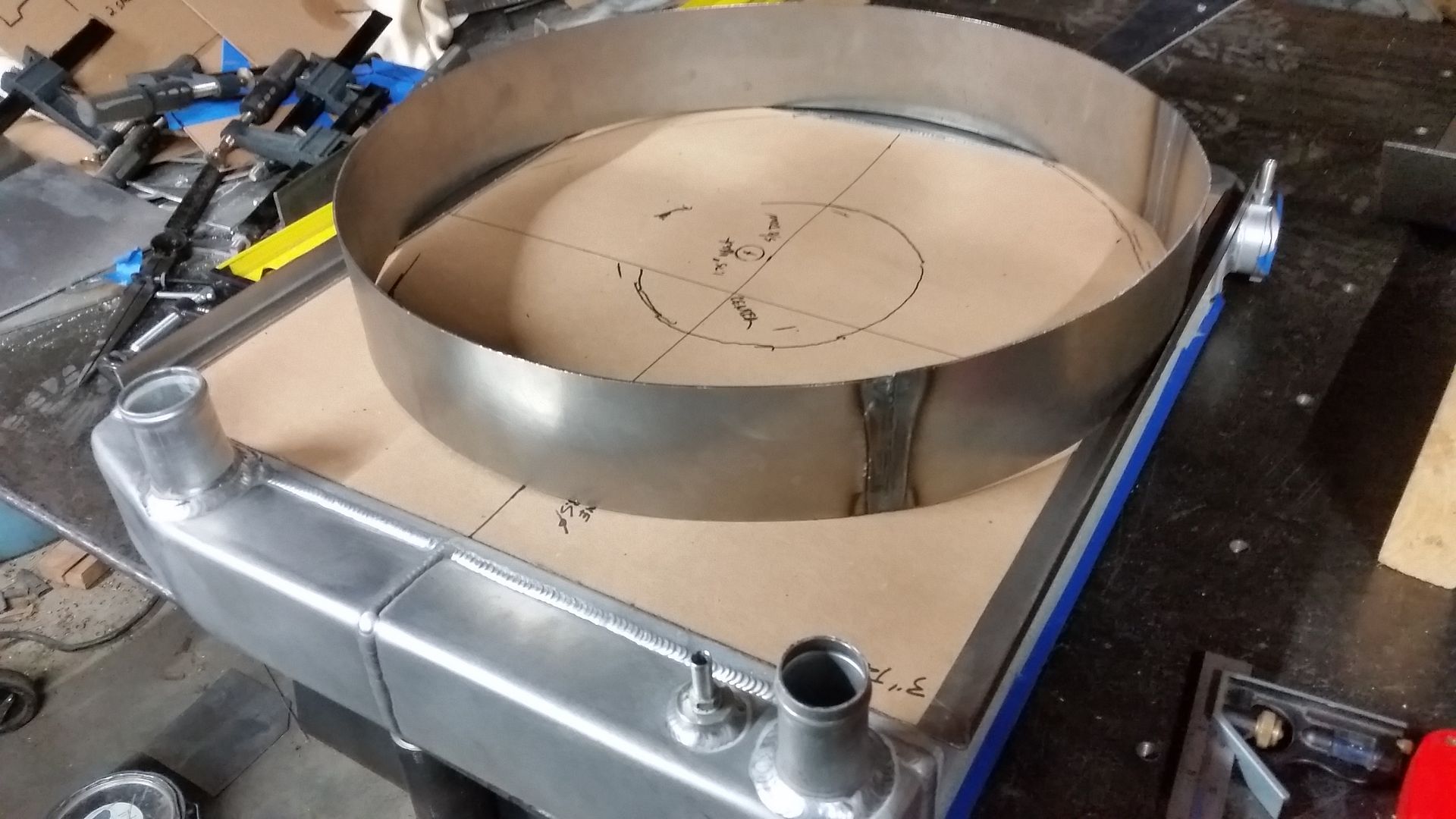

Made the main ring of the shroud. I didn't have long enough material to make the full circumference, so I had to weld in another seam. Other than that it was pretty easy. I formed it around a round thing ( an igloo water cooler ), to get it close. Then welded up the last seam on both sides....

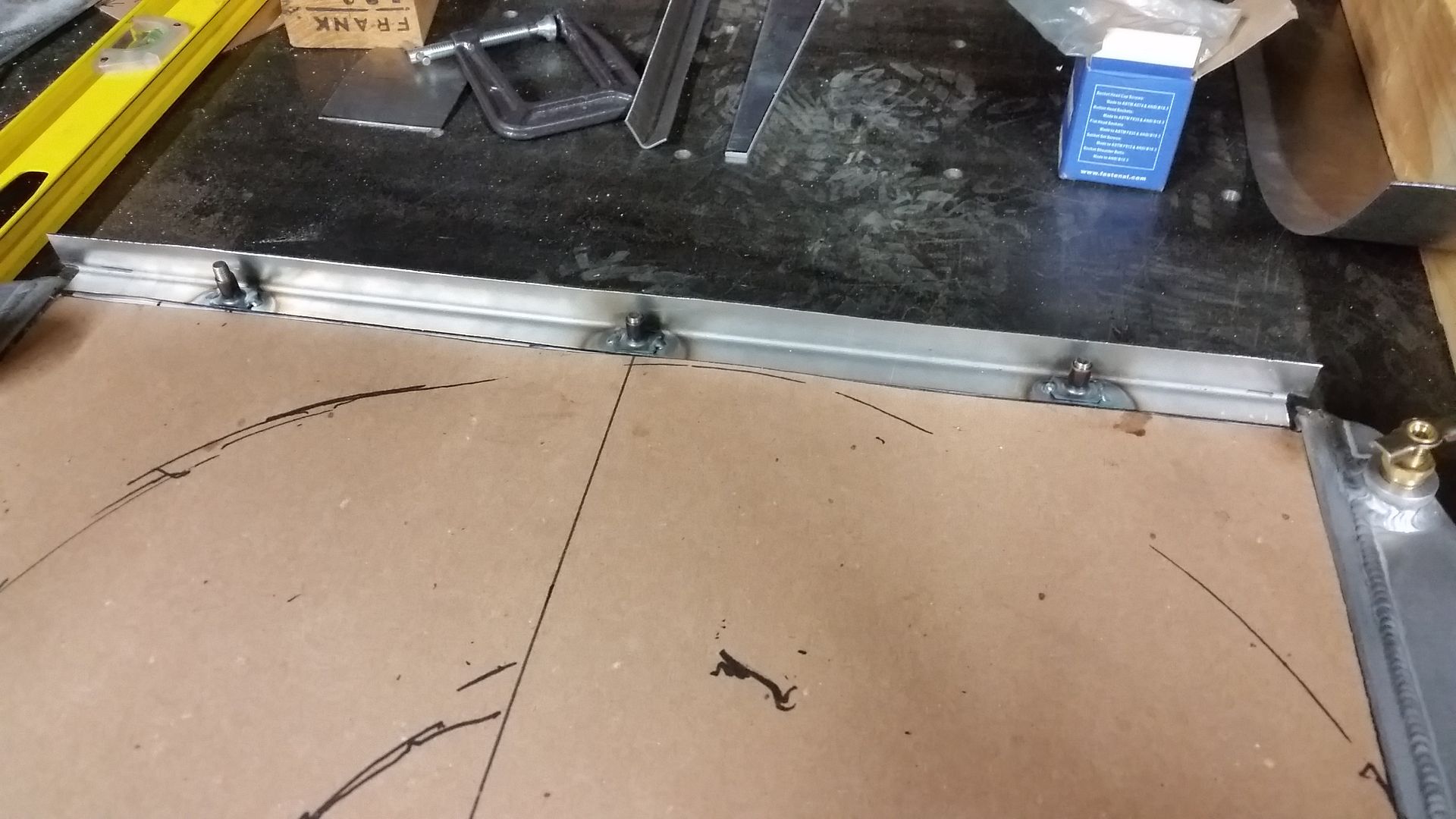

Last thing tonight was a few little angle brackets made for the top and bottom flange. I made these in my old press brake on the 20 ton HF press. These will have some weld nuts on the back to attach to the upper and lower flange on the radiator.

I should be able to hold the ring to the flanges with a cleco. Then I can double check the fit of the ring around the fan in the vehicle.

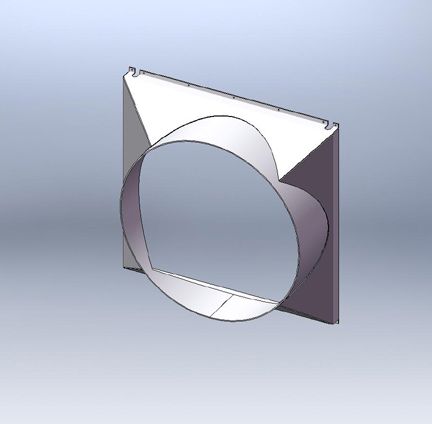

Once that is done I will make templates for the panels needed to close in the airflow to the core. Once I have those templates done, I will transfer them to metal and mark the ring for trimming. Then everything will get welded together.

I am also thinking about splitting the flange top to bottom with a set of angle flanges to allow taking it out in 2pc and/or access the fan clutch. Thoughts?