Metcalf

Expedition Leader

I have started a new project that is going to be a pseudo replacement for my 1942 Willys MB and my Dodge W250 that I built a few years back.

You can read about those builds here....

http://www.expeditionportal.com/forum/threads/58343-Rango-1942-Willys-MB

And.

http://www.expeditionportal.com/forum/threads/24653-Project-Doitall-Dodge

I am going to have to play a bit of catch up with this thread. I don't get over the Expo as much as I would like these days. I got sucked into the Willys section at Pirate4x4 when I was building my 1942 MB. That little thing opened a few doors for me. After taking it on a few trips to Moab and an epic 2000+ mile 13 day trip up north...

Read about that here....

http://www.pirate4x4.com/forum/jeep-willys/1280122-2000-miles-nervous-nirvana.html

...I was lucky enough to be one of the readers invited to attend the 2014 Ultimate Adventure trip hosted by 4-wheel and Off-road Magazine. That trip consisted of a crazy 3150 mile tour of the midwest. In 2015 I was invited back to Ultimate Adventure again as the Returning Reader. Once returning from that trip the gears in my head wouldn't stop grinding away at what to build next. I had another project lined up to build that was ( and still is ) a frustration. In a fit, I made the mistake of cruising Craigslist for a project. I knew generally what I was looking to build as far as the general package, but I didn't know what to start with.

After my adventures over the last few years, my wishlist has evolved as I spend more time neck deep in this sport. My Dodge has been a great vehicle for years. It is basically just a 1 ton diesel powered 4wd truck with big dumb tires. For a lot of things it works well. It has a top, doors, windows, heater, power, and gets good mileage. My ol' Willys, on the other hand, is open, small, short, limited to about 60mph, and did I mention small. While I love the little thing to death, and it is FAR more capable than I ever through a vehicle on 35" tires and an 85" wheelbase could be, it just isn't that practical.

What I really wanted was a blend ( ha...get it...blender ) of both those vehicles.

This is what I came up with so far....

-1996 LX450 ( same as FZJ80 ) chassis ( it was a super clean unit with only 110K miles that was flopped over in a ditch on a snowy road )

-1970 FJ45-esk custom pinched cab/tub ( which started out as a mostly rust free FJ40 tub from Arizona )

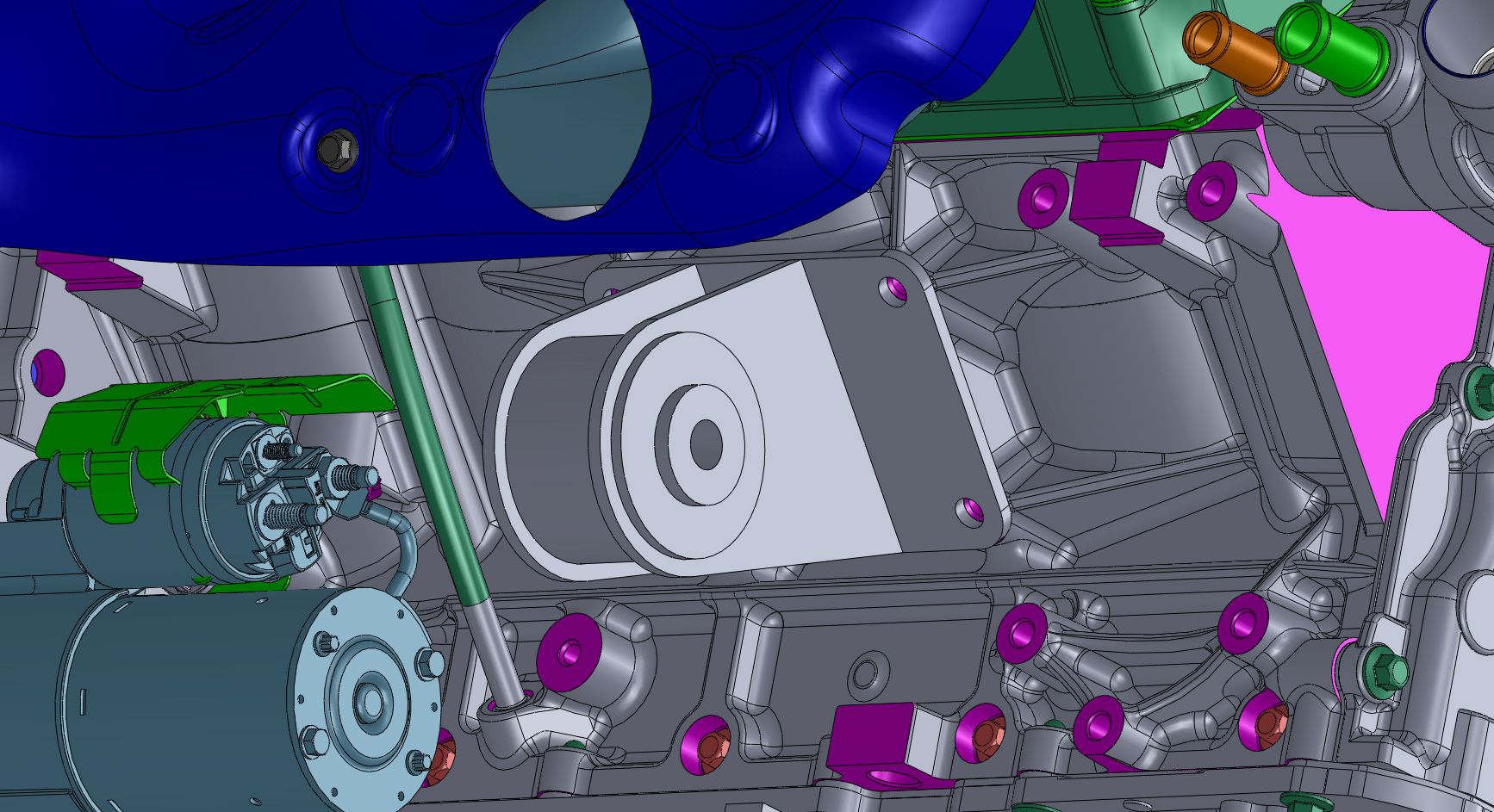

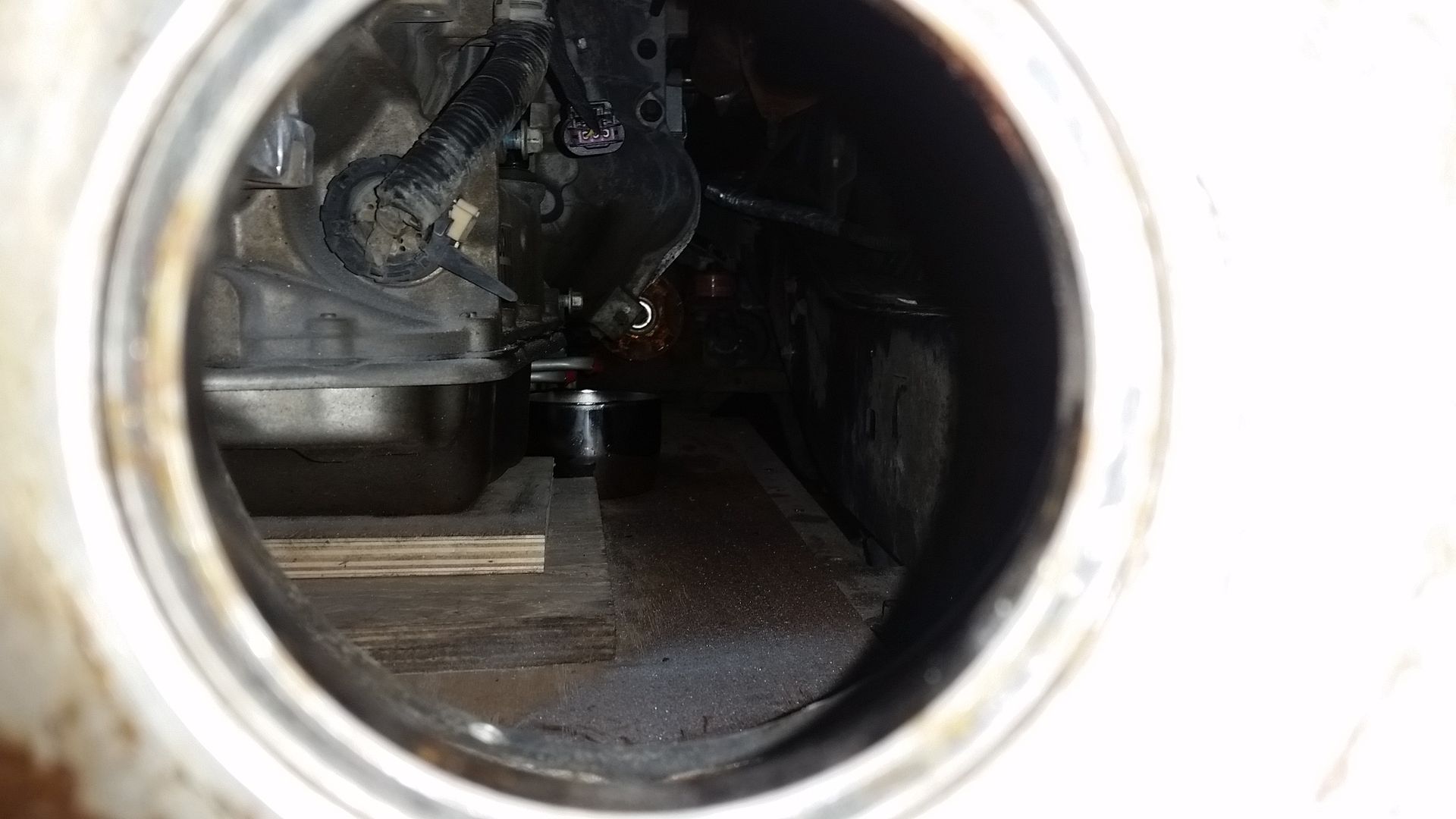

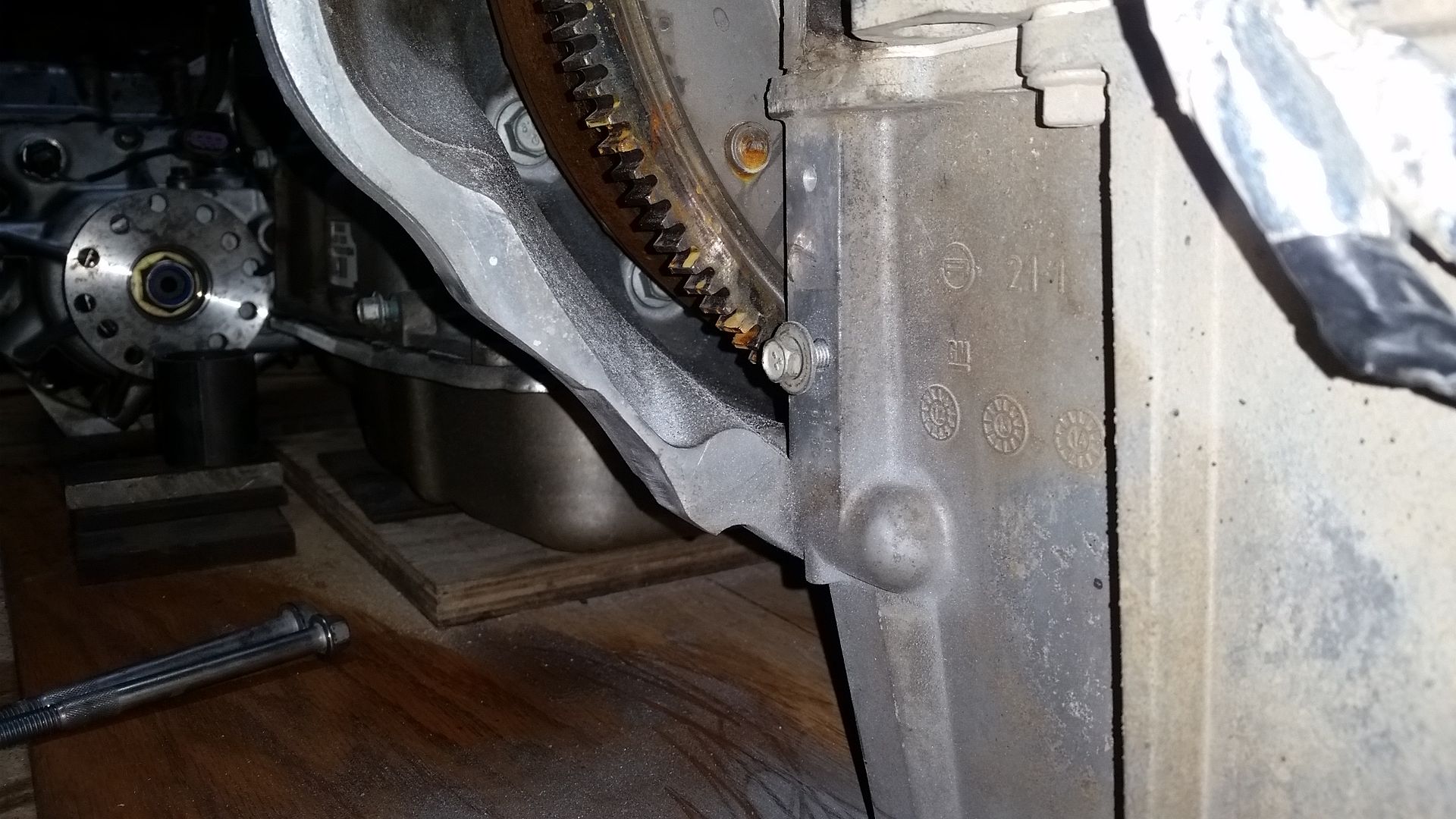

-2013 LC9 5.3 GM V8 all aluminum engine ( from a rolled truck with less than 50K miles )

-6L80E 6-speed automatic ( from the same truck as the engine and still attached from the factory )

-Land Rover LT230 transfer case ( from a Discovery2(?), it is the SE version with the unused center diff lock from the factory with 1.2 high range and 3.32 low range.

-Toyota Factory 4.10 E-Locker Differentials ( that came in the LX450 from the factory )

-40" Tires and Beadlock wheels ( because I like big dumb tires )

-Warn 8274 winch

In general I wanted ( no real specific order )

-About a 110" wheelbase, the J80 chassis is 112" (close enough)

-Modern, reliable V8 power with about 300hp, cheap, with easy to find parts.

-Automatic transmission. I think for the technical 'wheeling they do have an advantage.

-BROAD gearing, not just low gearing. I like being able to run between harder section of the trail, and in the sand/desert, without having to do the low-hi range shuffle.

-Be able to travel at modern interstate speeds of 75-80mph without needing a death grip on the wheel and focused concentration.

-Cruise control. I seem to always go on these long adventures....

-Flat smooth belly at about 1/2 tire diameter. I tend to build vehicles very low for stability and handling. To make that work I try and maximize the belly clearance while keeping it as smooth as practical.

-Limited front overhang. Just enough room for the winch past the grill. It won't be a 90 degree approach angle, but close

-Limited rear overhang. With the longer wheelbase you can more easily get the front end up on very large obstacles. If the rear end gets in the way your forward/upward progress stops

-25-30 gallon fuel capacity that doesn't get in the way

-Full float rear axle because semi-float shafts suck when they break, or bend, when you're doing stupid stuff you shouldn't (check)

-Serviceable wheel bearings, because I like being able to inspect/replace/repack those parts (check)

-Big dumb tires, because I feel that allows me to do crazy things that I like to do.

-Room for a big dumb spare tire that will not get in the way of rearward visibility

-4 wheel disc brakes, to help stop the big dumb tires.

-Coil/link suspension, to help with approach and departure angles along with provide a more complaint 'modern' ride quality.

-Front end weight bias, so that when it is loaded down for larger trips it is still close or better than 50/50 front to rear.

-Smaller body. I want the body to be comfortable for 2 people, but no bigger than needed for tight trail work.

-Almost no lift. I like running big dumb tires, but I don't like using feet of 'lift' to do it.

-Modular lockable hard top. While I enjoy an open air high visibility driving immersion in the environment, I hate getting hit in the back of the ear by tire spray on the highway.

-Doors, that lock, with windows

-Heater

-Good ventilation, but no complex heavy complicated A/C systems

-Comfy interior

-etc

-etc

I have a thread in the wrong section of pirate here...

http://www.pirate4x4.com/forum/jeep-willys/2126506-jumping-ship.html

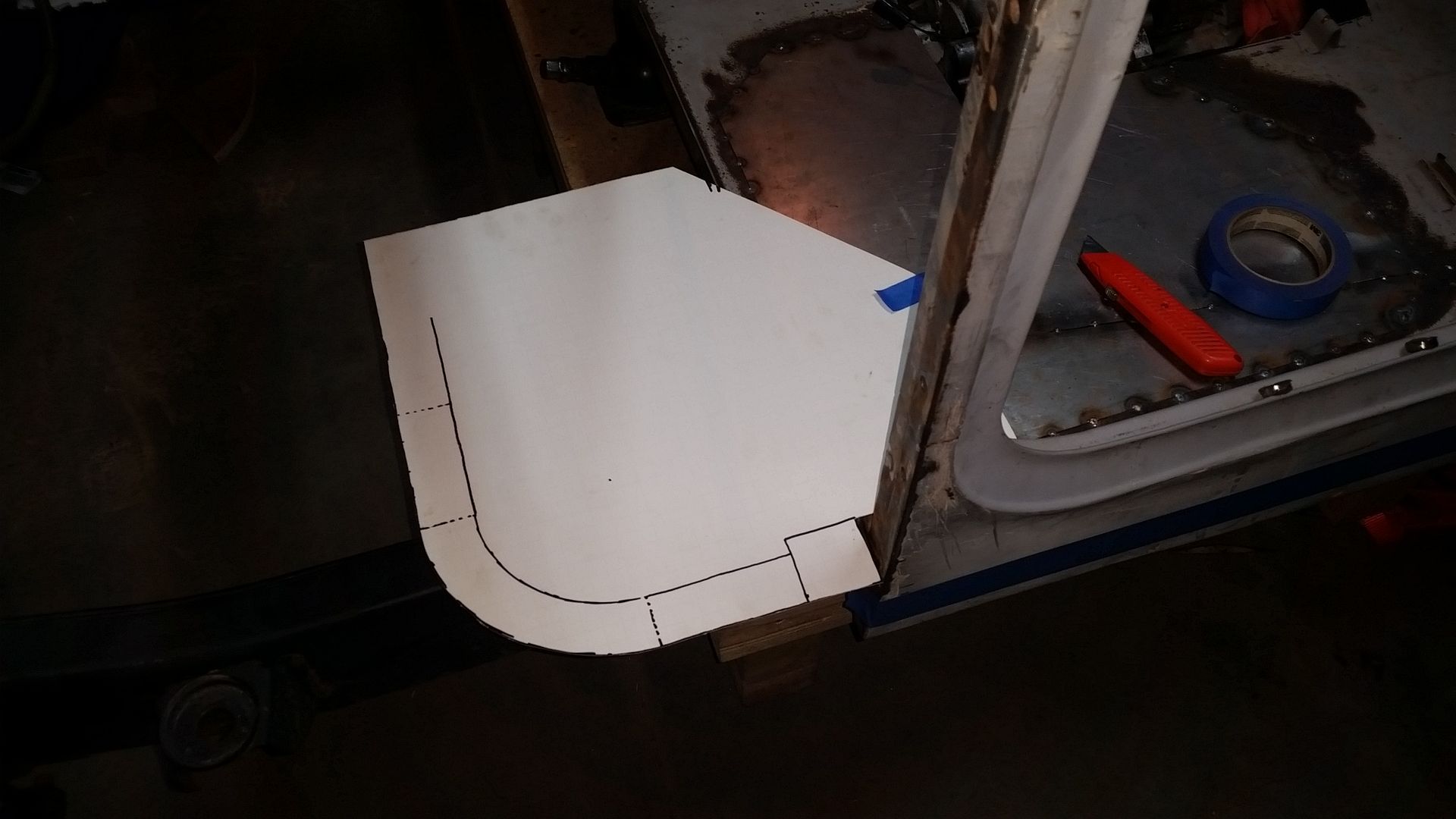

I will be taking off from the point in the above picture in this thread. If you want to ask questions from the stuff in that other thread feel free.

I like questions. I like hearing other points of view and criticism on my dumb ideas.

And go....

You can read about those builds here....

http://www.expeditionportal.com/forum/threads/58343-Rango-1942-Willys-MB

And.

http://www.expeditionportal.com/forum/threads/24653-Project-Doitall-Dodge

I am going to have to play a bit of catch up with this thread. I don't get over the Expo as much as I would like these days. I got sucked into the Willys section at Pirate4x4 when I was building my 1942 MB. That little thing opened a few doors for me. After taking it on a few trips to Moab and an epic 2000+ mile 13 day trip up north...

Read about that here....

http://www.pirate4x4.com/forum/jeep-willys/1280122-2000-miles-nervous-nirvana.html

...I was lucky enough to be one of the readers invited to attend the 2014 Ultimate Adventure trip hosted by 4-wheel and Off-road Magazine. That trip consisted of a crazy 3150 mile tour of the midwest. In 2015 I was invited back to Ultimate Adventure again as the Returning Reader. Once returning from that trip the gears in my head wouldn't stop grinding away at what to build next. I had another project lined up to build that was ( and still is ) a frustration. In a fit, I made the mistake of cruising Craigslist for a project. I knew generally what I was looking to build as far as the general package, but I didn't know what to start with.

After my adventures over the last few years, my wishlist has evolved as I spend more time neck deep in this sport. My Dodge has been a great vehicle for years. It is basically just a 1 ton diesel powered 4wd truck with big dumb tires. For a lot of things it works well. It has a top, doors, windows, heater, power, and gets good mileage. My ol' Willys, on the other hand, is open, small, short, limited to about 60mph, and did I mention small. While I love the little thing to death, and it is FAR more capable than I ever through a vehicle on 35" tires and an 85" wheelbase could be, it just isn't that practical.

What I really wanted was a blend ( ha...get it...blender ) of both those vehicles.

This is what I came up with so far....

-1996 LX450 ( same as FZJ80 ) chassis ( it was a super clean unit with only 110K miles that was flopped over in a ditch on a snowy road )

-1970 FJ45-esk custom pinched cab/tub ( which started out as a mostly rust free FJ40 tub from Arizona )

-2013 LC9 5.3 GM V8 all aluminum engine ( from a rolled truck with less than 50K miles )

-6L80E 6-speed automatic ( from the same truck as the engine and still attached from the factory )

-Land Rover LT230 transfer case ( from a Discovery2(?), it is the SE version with the unused center diff lock from the factory with 1.2 high range and 3.32 low range.

-Toyota Factory 4.10 E-Locker Differentials ( that came in the LX450 from the factory )

-40" Tires and Beadlock wheels ( because I like big dumb tires )

-Warn 8274 winch

In general I wanted ( no real specific order )

-About a 110" wheelbase, the J80 chassis is 112" (close enough)

-Modern, reliable V8 power with about 300hp, cheap, with easy to find parts.

-Automatic transmission. I think for the technical 'wheeling they do have an advantage.

-BROAD gearing, not just low gearing. I like being able to run between harder section of the trail, and in the sand/desert, without having to do the low-hi range shuffle.

-Be able to travel at modern interstate speeds of 75-80mph without needing a death grip on the wheel and focused concentration.

-Cruise control. I seem to always go on these long adventures....

-Flat smooth belly at about 1/2 tire diameter. I tend to build vehicles very low for stability and handling. To make that work I try and maximize the belly clearance while keeping it as smooth as practical.

-Limited front overhang. Just enough room for the winch past the grill. It won't be a 90 degree approach angle, but close

-Limited rear overhang. With the longer wheelbase you can more easily get the front end up on very large obstacles. If the rear end gets in the way your forward/upward progress stops

-25-30 gallon fuel capacity that doesn't get in the way

-Full float rear axle because semi-float shafts suck when they break, or bend, when you're doing stupid stuff you shouldn't (check)

-Serviceable wheel bearings, because I like being able to inspect/replace/repack those parts (check)

-Big dumb tires, because I feel that allows me to do crazy things that I like to do.

-Room for a big dumb spare tire that will not get in the way of rearward visibility

-4 wheel disc brakes, to help stop the big dumb tires.

-Coil/link suspension, to help with approach and departure angles along with provide a more complaint 'modern' ride quality.

-Front end weight bias, so that when it is loaded down for larger trips it is still close or better than 50/50 front to rear.

-Smaller body. I want the body to be comfortable for 2 people, but no bigger than needed for tight trail work.

-Almost no lift. I like running big dumb tires, but I don't like using feet of 'lift' to do it.

-Modular lockable hard top. While I enjoy an open air high visibility driving immersion in the environment, I hate getting hit in the back of the ear by tire spray on the highway.

-Doors, that lock, with windows

-Heater

-Good ventilation, but no complex heavy complicated A/C systems

-Comfy interior

-etc

-etc

I have a thread in the wrong section of pirate here...

http://www.pirate4x4.com/forum/jeep-willys/2126506-jumping-ship.html

I will be taking off from the point in the above picture in this thread. If you want to ask questions from the stuff in that other thread feel free.

I like questions. I like hearing other points of view and criticism on my dumb ideas.

And go....

Last edited: