Well up early and ready to install the drivers seat today. To keep the adjustable base from the original seat and use it on the new unit the base and seat pan needs to be separated. I can either cut the pan apart using a skinny wheel or drill out the spot welds using a spot weld remover, after all of 30 seconds I decided removing the spot welds would be cleaner overall so I set out to separate the two.

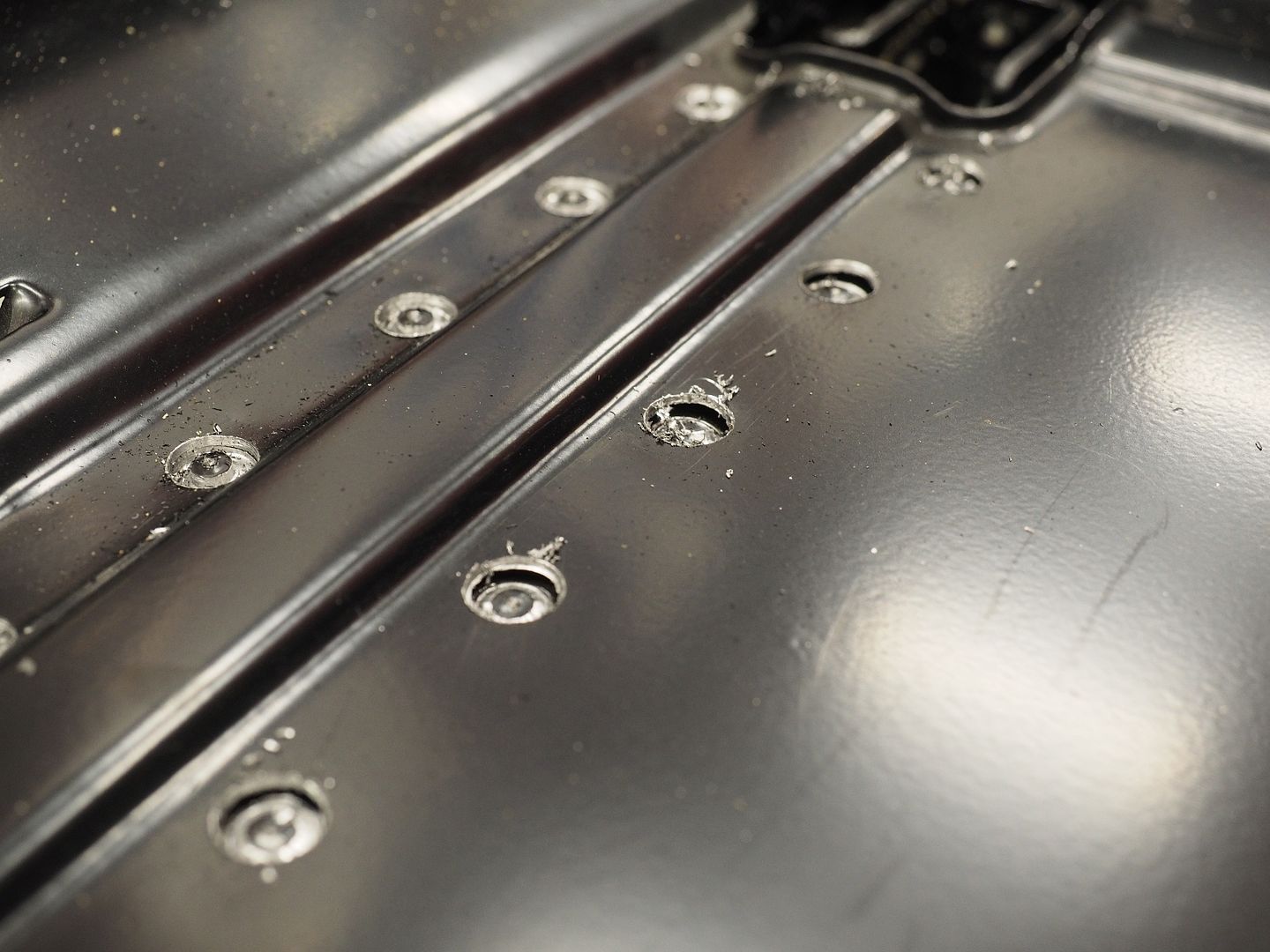

Here's the spot weld remover bit, it quickly chews through the first layer and separates the two pieces of metal. You use a center punch to mark the center of the spot weld then use this tool to drill the weld out, the center of the tool is spring loaded and retracts as you drill keeping the bit on coarse.

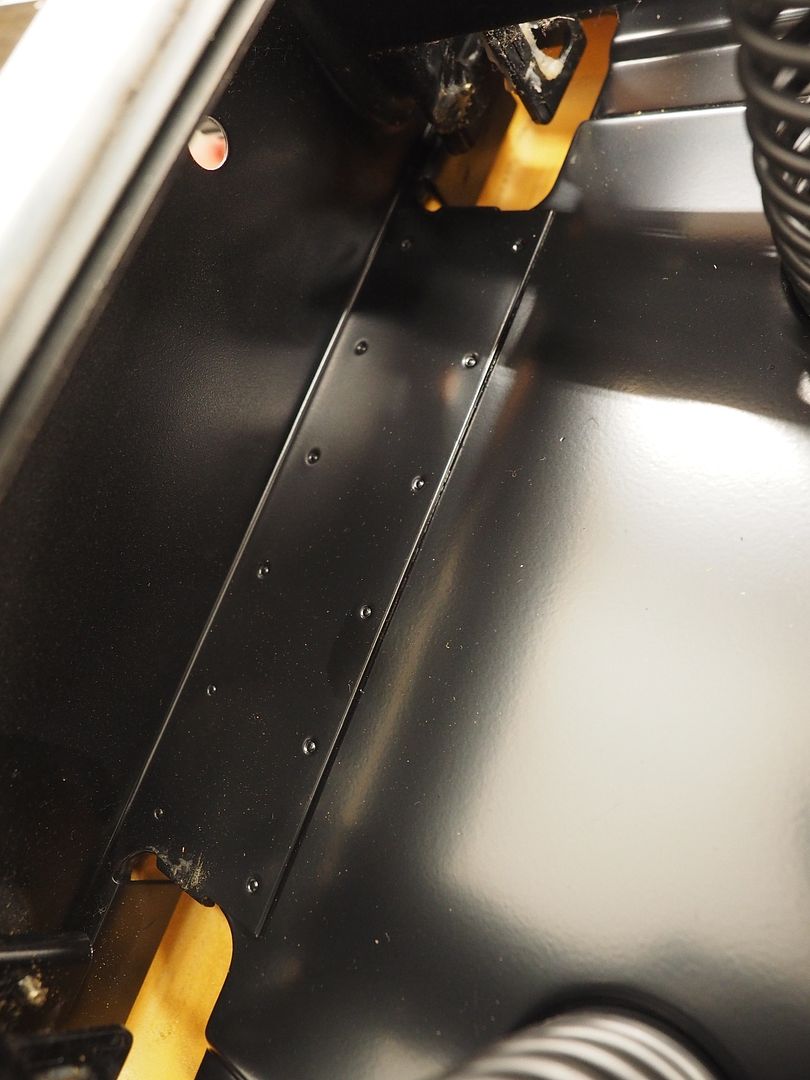

And the spot welds before and after drilling, you can see the two pieces separating here.

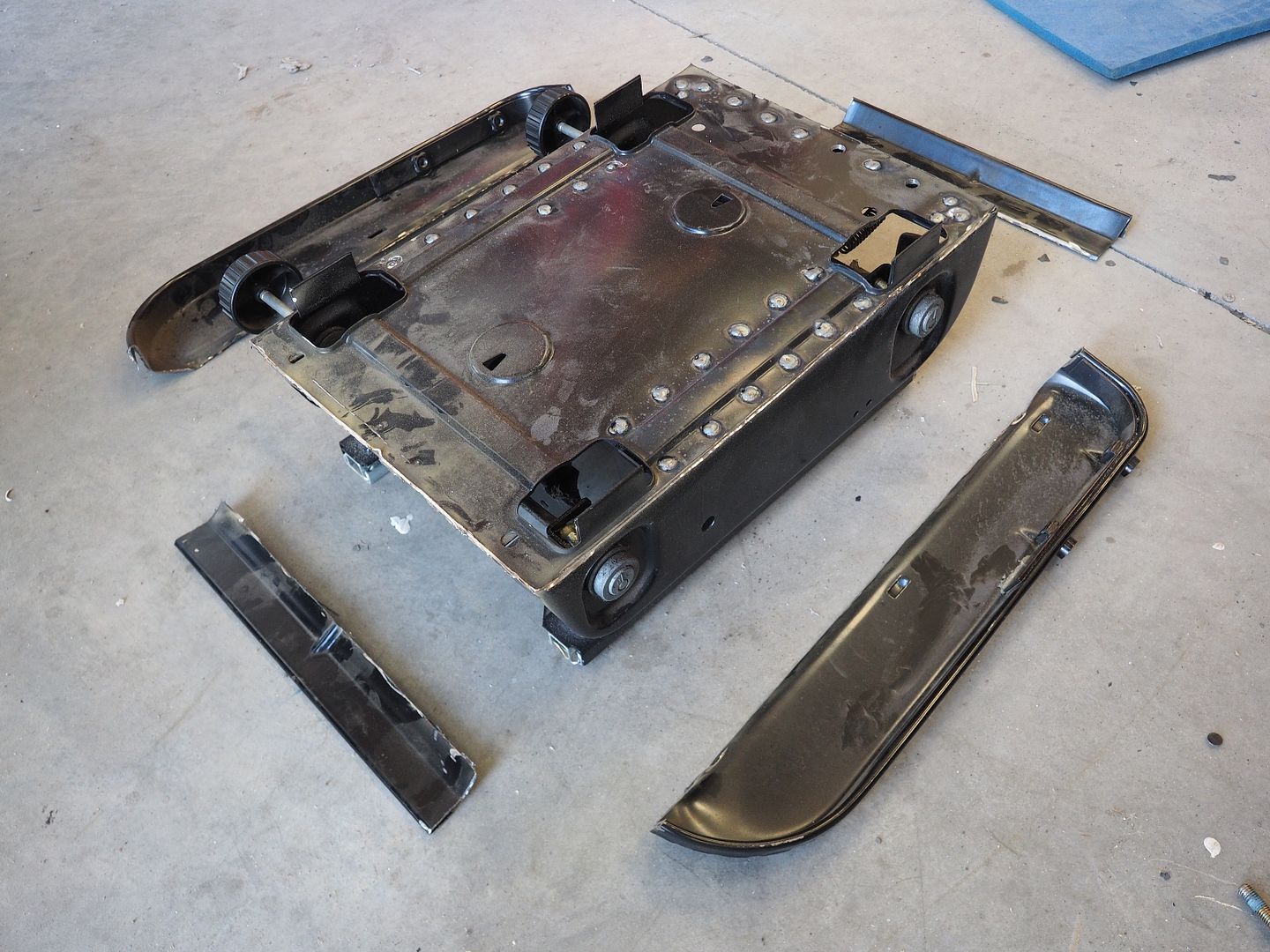

Soooo.....now we have a lesson in thinking things ALL the way through before you start working on something. There are two stiff springs on the bottom side on the base that keep tension on the adjustment mechanism, as I started removing the spot welds it became apparent that the seat pan was the upper restraint for the springs and removing the spot welds wasn't an option. Out came the Mig machine and a few minutes later the spot welds were put right back where they were when I started LOL. Time to get out the skinny wheel

Here the tabs sticking up on top have been removed and I've shortened the adjusting bars on all 4 corners to allow clearance for the new seat to go lower, the new seat is slightly taller than the old one.

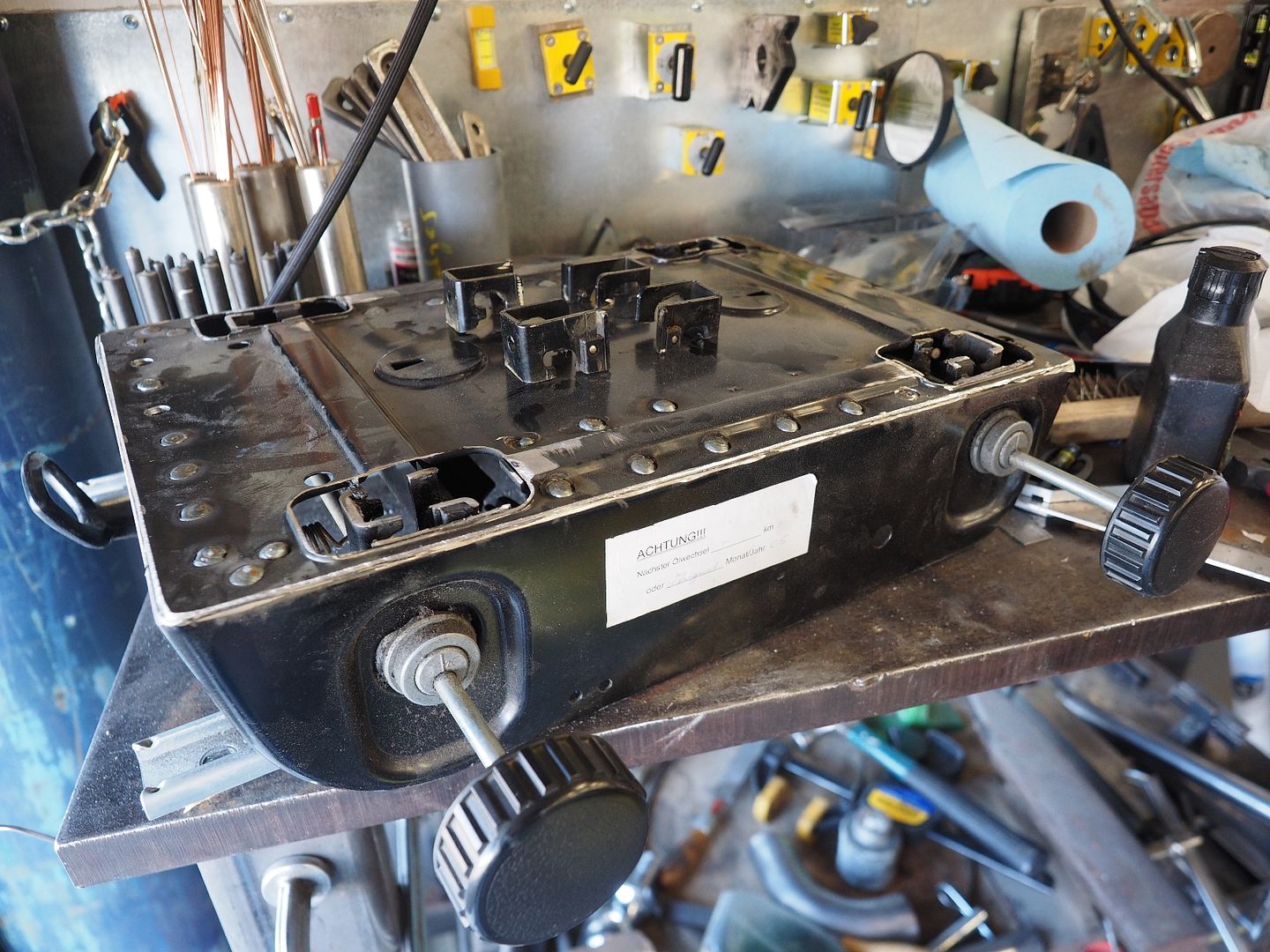

Stops tack welded in place to keep the adjusting mechanism from coming apart if the adjusting wheel is turned to far.

Mounting bars installed, these were needed for the new seat to clear the adjustment bars.

Installed in the truck. The seat is very comfortable compared to the OEM unit and adds a bit of modern look to the interior as well. Glad I kept the height adjustment as I like to run the seat up very high but anyone with a heavier build will need to lower the seat to drive it. When I pull the seat back out I'll blend down the edges and paint the needed bits.

I ordered another suspension base to install on the passenger side seat as well, hopefully it will help out with my father bad back when on long trips. I also want to raise the passenger seat up to the drivers seat height, it feels like sitting in a hole when your riding on that side with the bench seat. You can see the current height difference in this pic.

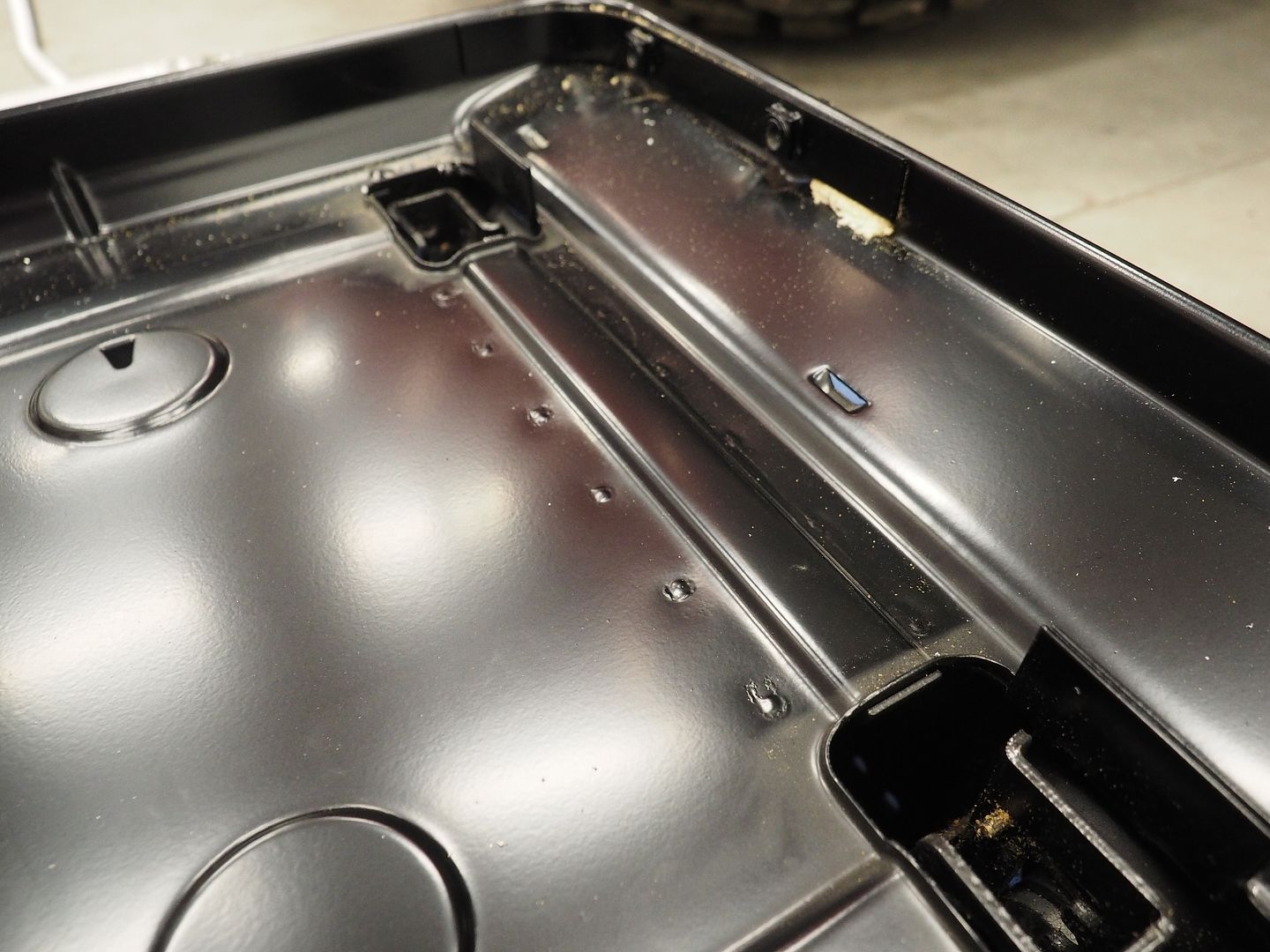

Started stripping the truck down for paint & powder coat prep that will hopefully start soon. Still have several holes to fill on top of the cab from the old radio antennas as well.

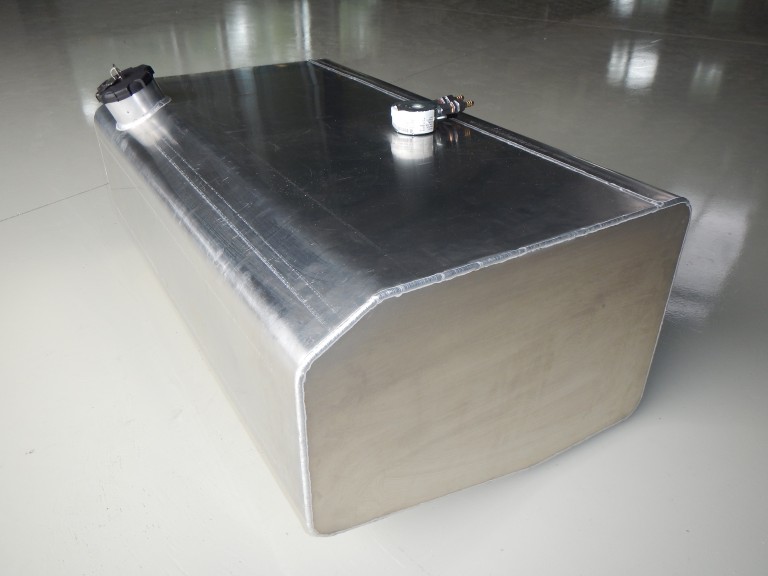

Parts that will be going out for powder coating soon. The mounting tabs on the front fenders had a thick layer of rubbery sealant applied under the paint all the way around each bracket to keep out moisture. We didn't want the powder coating place to warp the sheet metal trying to get that stuff out with a sand blaster so my father carefully removed it all with hand tools. There will be more to powder coat but this will be a start.

Hodakaguy