Jscherb, I have no where near the talents you do in as many areas, so one of the ideas I have thought about was doing just as you have but then adding a RTT (one of the fiberglass hardshells, one is only 8" height) on top. Idea is someone has already figured out the hinges, tent, and mattress for me and would in theory make the project go faster. What challenges do you see for this? I had already thought about the need to make sure RTT was attached/supporters by rollbars and that I am cutting into a hardtop + rtt. What would be the best way to bond rtt to hardtop? Would I need to reinforce the rtt floor/ what would be the best way for that? By the way I apologize in advance if my wife calls cursing your name

The fiberglass hard shell RTTs are designed to be mounted on roof rack bars so the floors are made strong enough to handle that mounting; I wouldn't think you'd need to do any reinforcement or strengthening of the unit itself.

If I were planning to mount one of these on a factory hardtop, the first thing I'd do is research roof racks for factory hardtops. I'm not talking about the Exocage racks like the Gobi, I mean things like the Surco Safari Rack, the Rhino Rack Vortex Bar Roof Rack and the Smittybilt Defender, among others. I'd see if any of these have both the dynamic and static weight capacity to support the unoccupied tent while driving and the occupied tent when camped. (I'm just listing a few of the ones I'm aware of, I have no idea if they have the weight capacity).

If none of them had the capacity, I'd look at the Teraflex Nebo rack, which comes with brackets to tie it to the roll bars and has a static load rating of 850 lbs.

If you didn't like any of them, or found them too expensive, you could pick up up a junkyard Cherokee rack (or any other SUV rack you happen to like) and support it to the roll bar with brackets you could make. The photo below shows one of the brackets that support the rear of the Cherokee rack I have on my Safari Cab. You could also take a close look at the brackets that come with the Nebo rack and try to build something like that yourself.

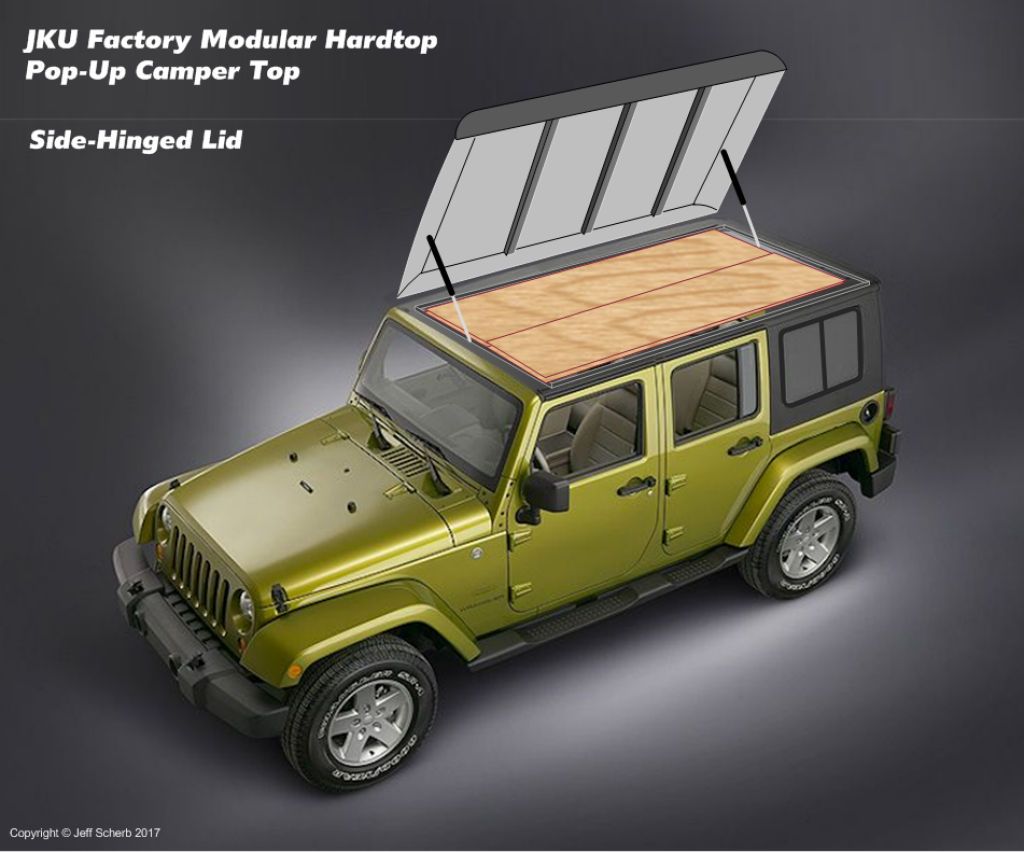

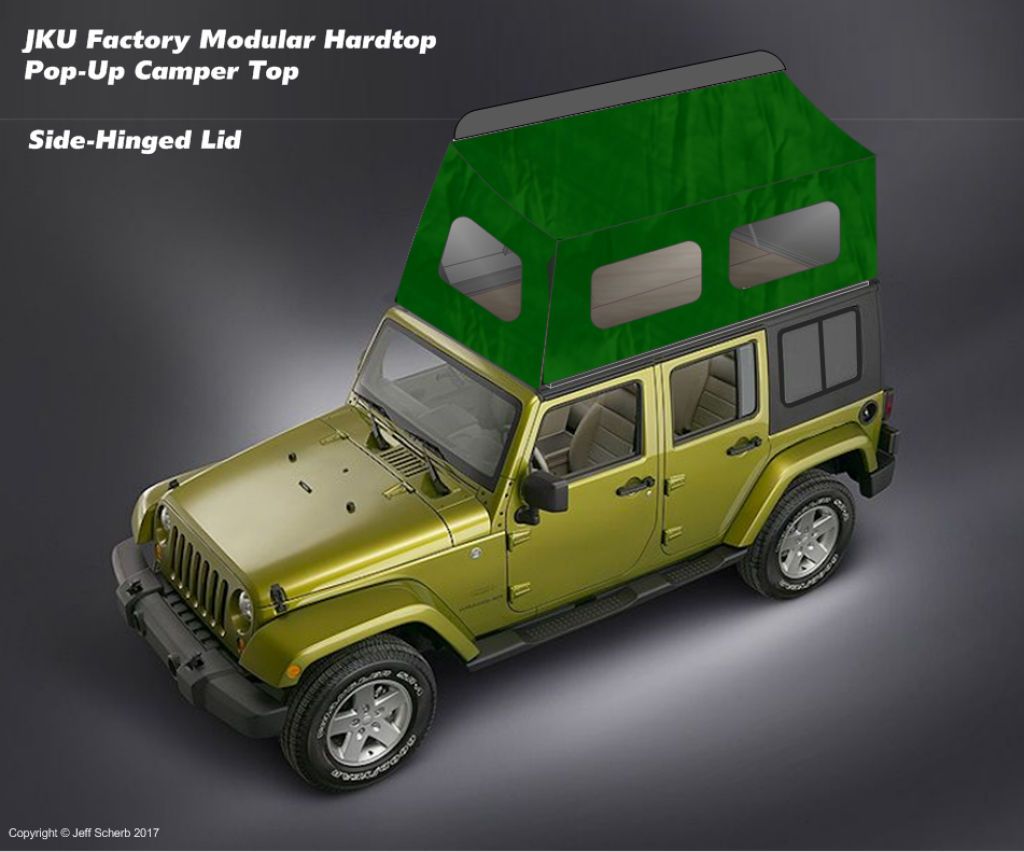

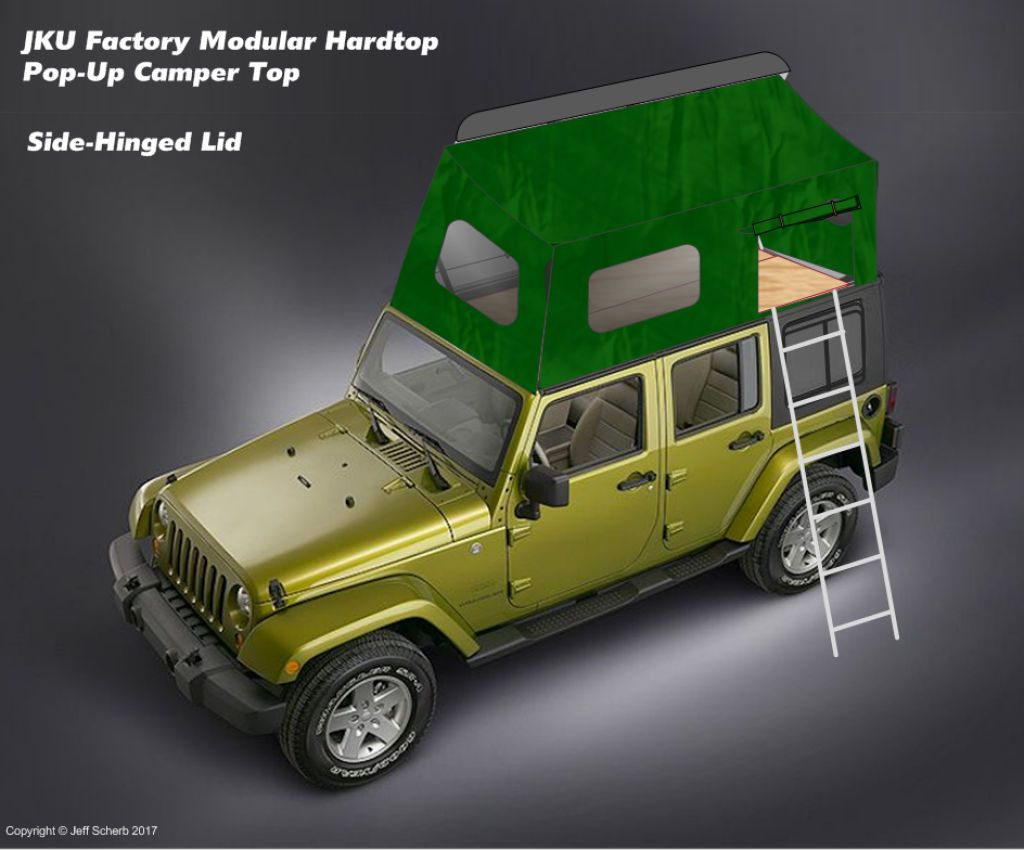

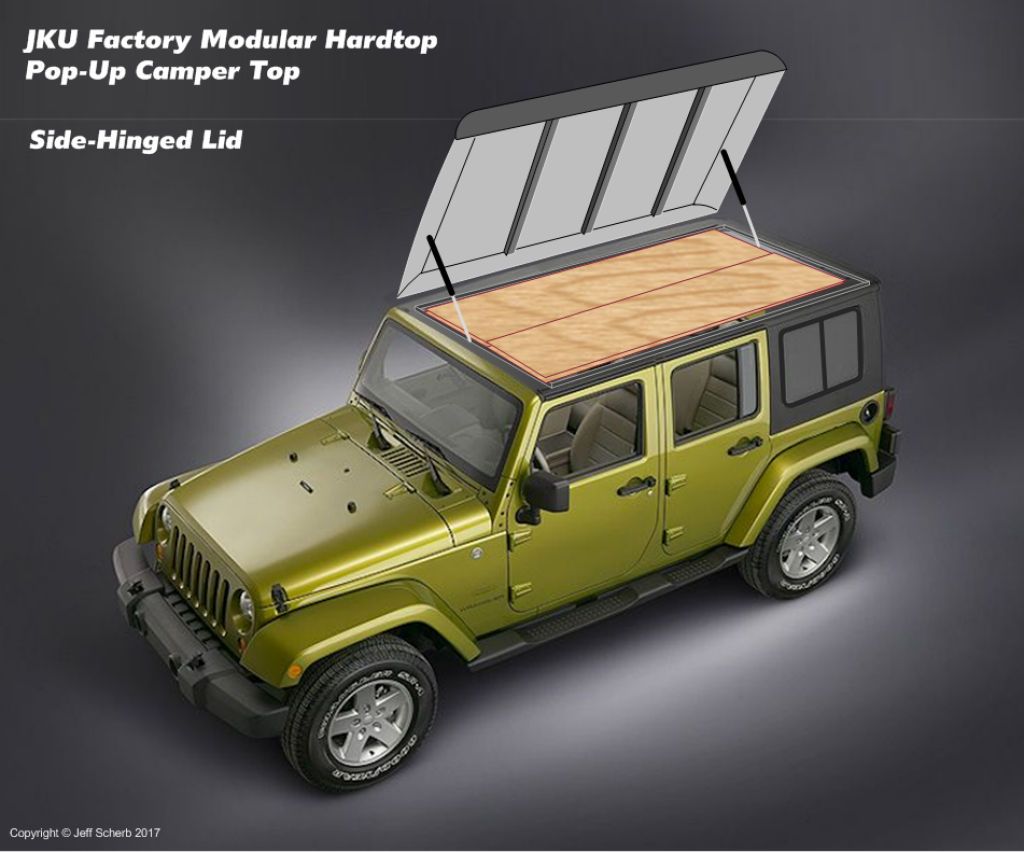

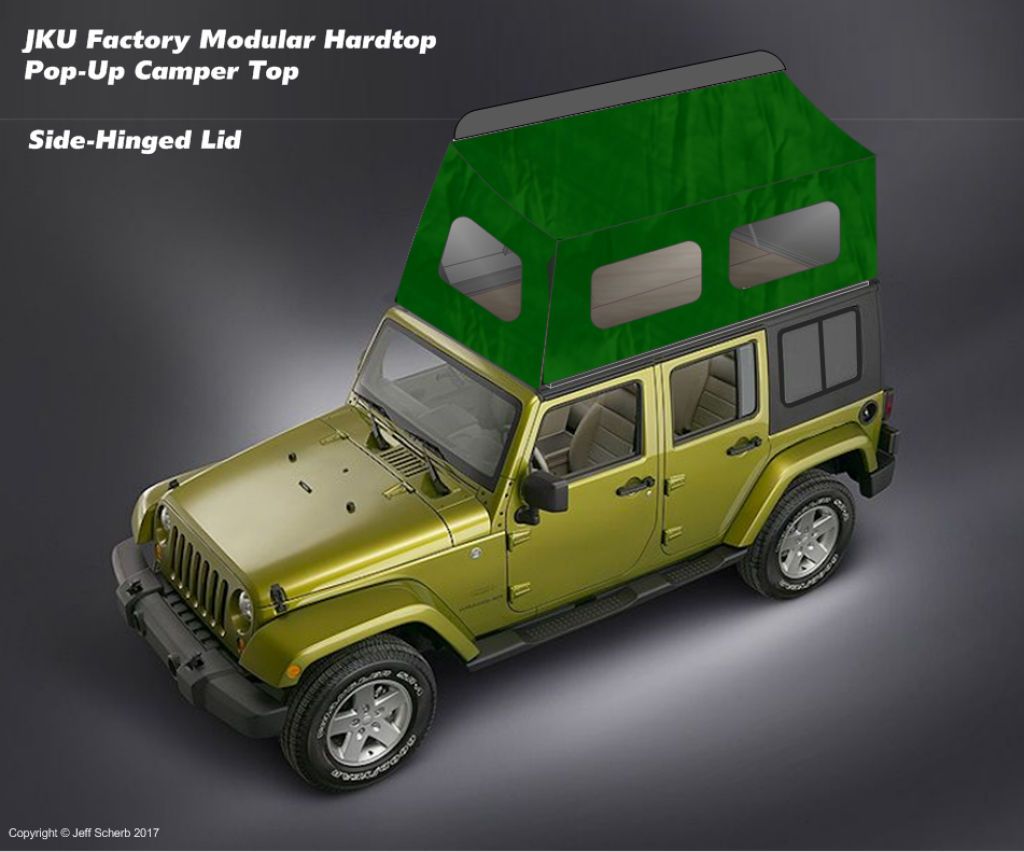

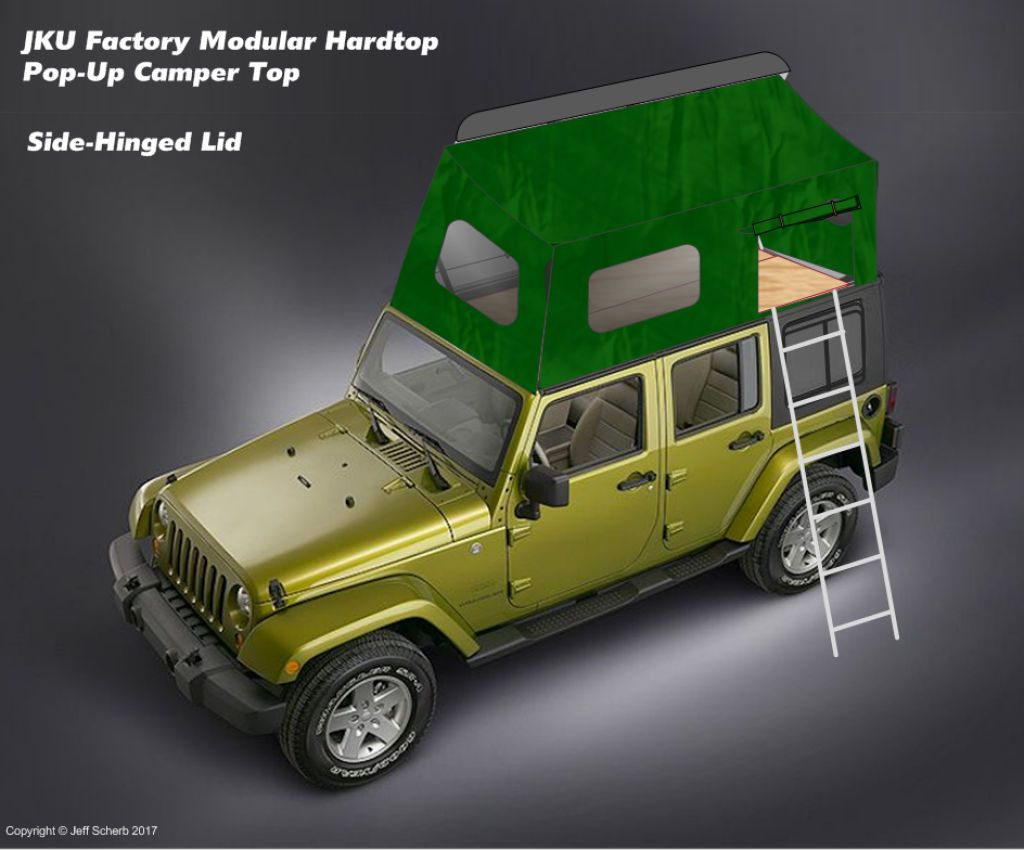

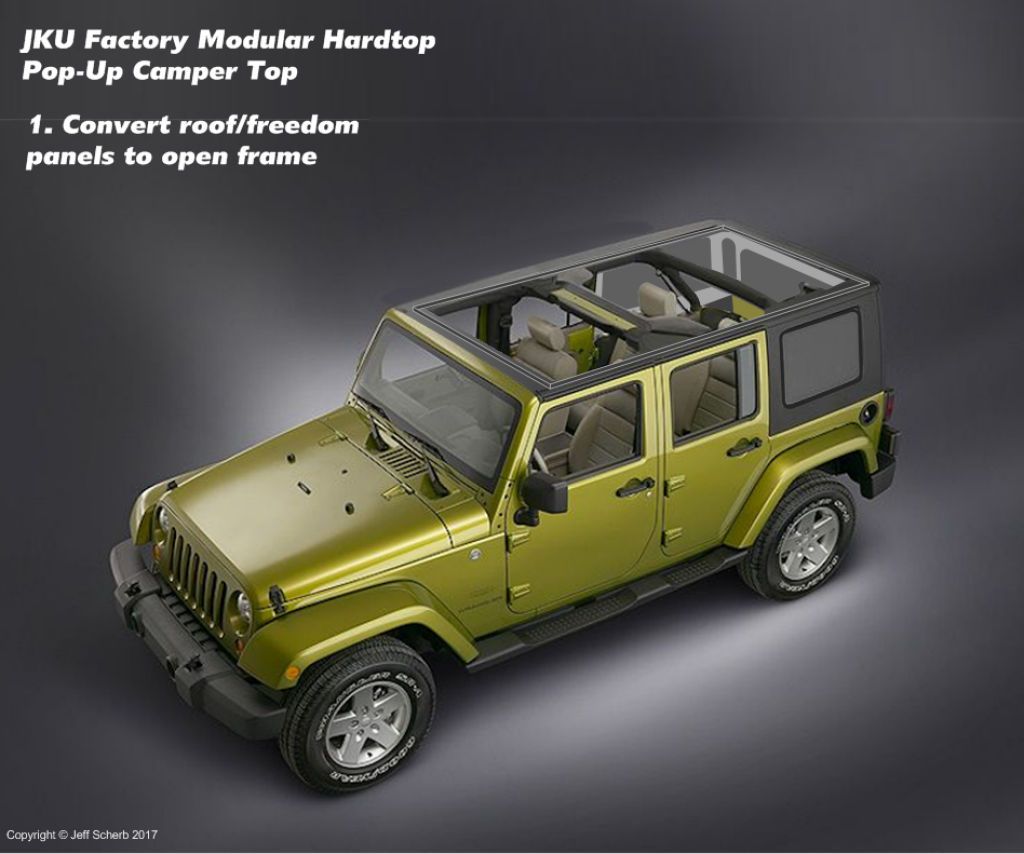

I've often thought of building a clamshell-type RTT from scratch, I could use the upper shell and canvas from my Jeep-tub trailer and make a matching lower half shell, hinge it like a clamshell and mount it to a roof rack, here's a concept drawing I did a few years ago when I was working on the TrailTop project. The appeal of doing this is that I could do any size clamshell I wanted, I find most the commercial clamshells a bit cramped for my 6' 6" size, and it would be less expensive than a commercial one.

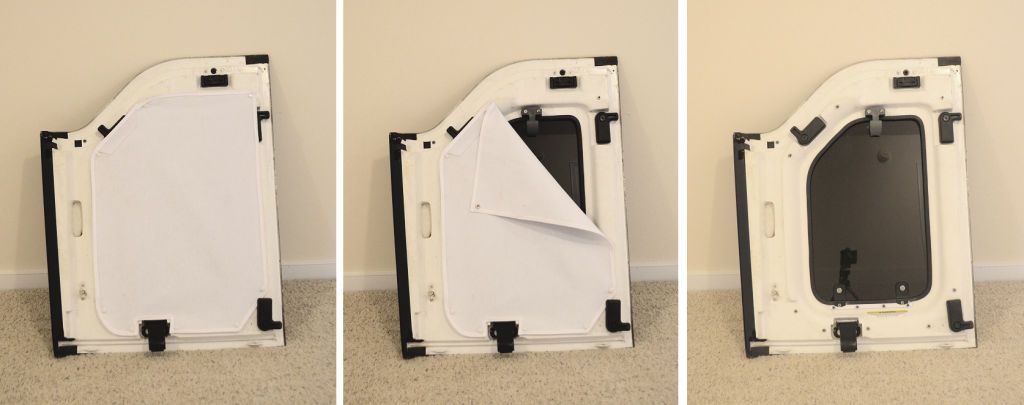

The top half of the clamshell and the canvas could be repurposed to make the full clamshell above: