CoyoteThistle

Adventurer

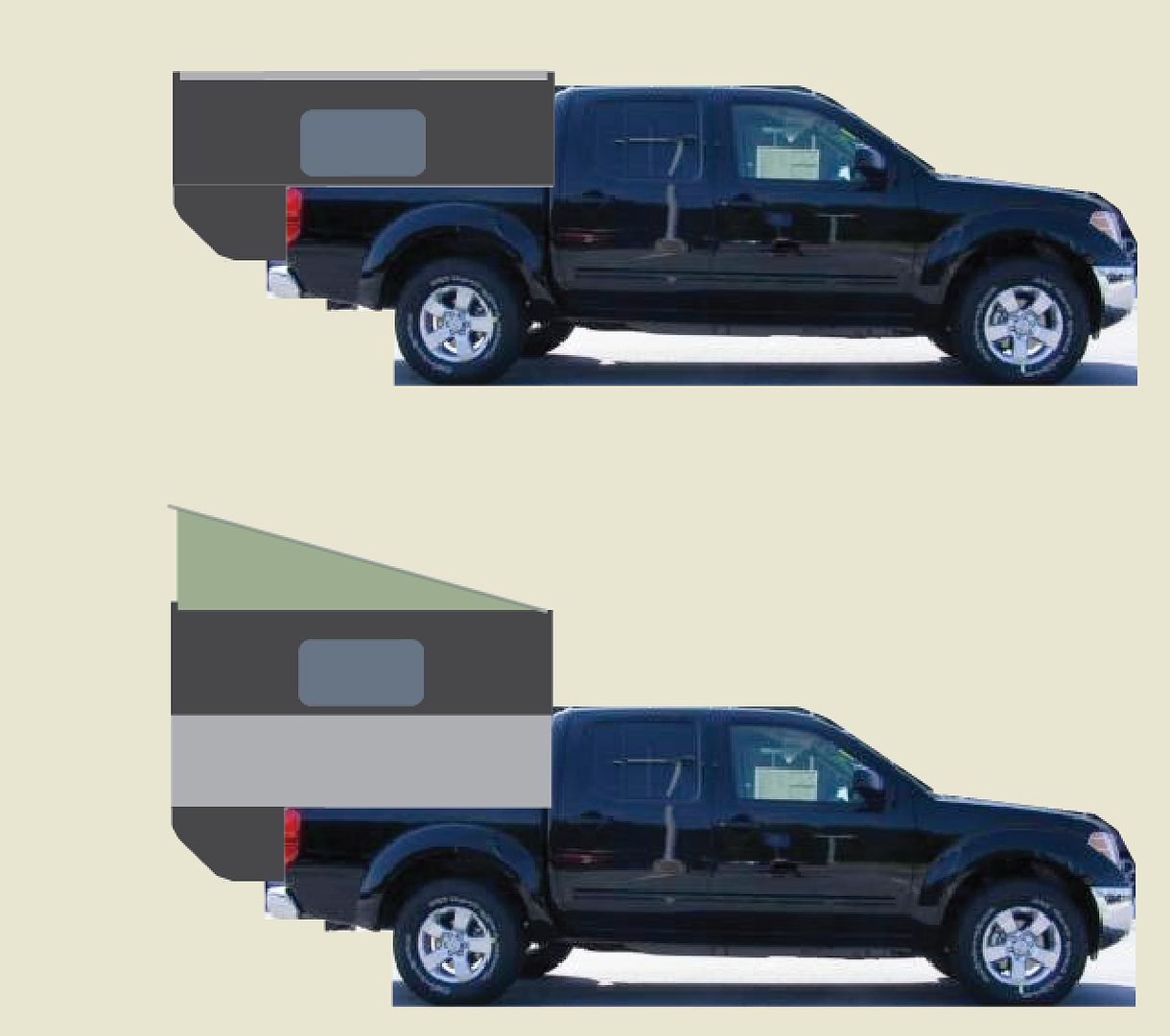

Well, I'm about six months in to this build and progress has been slow but steady. Here's how it looks as of about a week ago:

It's (obviously) a slide in. It will be a double pop-up - the structure on the foreground in the photos is the hard-sided part of the pop-up (upside down). It will slide up vertically giving about 5 feet of headroom. The second part of the pop up will be a Westfalia-style hinged roof with canvas sides. The idea is, if the weather is bad we can close the canvas part and still do everything inside (except stand up straight). In the "down" mode for travel, it should be just a couple inches taller than the cab of the truck (Nissan Frontier 4-door short bed).

The building material is a honeycomb core with 2.7mm plywood skins (more on this later). I went with the plywood composite over a fiberglass composite primarily due to the fact that I'm building this in my garage and the thought of all that fiberglass dust all over everything was a deal breaker. Most of the camper exterior will then get a layer of fiberglass to give it some extra impact resistance. Aluminum angle is bonded on with 3m 5200 to protect/strengthen the outside corners. Joints are mostly butt joints - I fill the honeycomb with thickened epoxy and then clamp the joint together (usually overnight at least). The inside corners then get a fillet and 3" fiberglass tape. Outside corners get 6" tape where they don't get aluminum.

Since I don't have one of those cool 3-D graphics that others manage to do, you'll have to see the design unfold as it comes together.

The interior as it sits:

The interior is made of composites too, making the whole thing (hopefully) really strong. My floor plan prioritized getting the heavy stuff forward and including the "must-haves" that my girlfriend requested - inside shower, porta potty, 2-burner stove, fridge with freezer, battery-that-doesn't-go-dead-all-the-time, queen size bed with sit-up headroom, dinette seating, hot water, heater and, most importantly, "I don't want it to look home made". Well, that's a lot to cram in to a small camper and a tall order for someone with no experience in building this type of thing. Never mind, it's worth a try!

Lots or work yet to go. Currently working on getting the electrical, water and propane systems installed and still lots to do on painting and finishing construction of the roof.

Updates to follow!

matt

It's (obviously) a slide in. It will be a double pop-up - the structure on the foreground in the photos is the hard-sided part of the pop-up (upside down). It will slide up vertically giving about 5 feet of headroom. The second part of the pop up will be a Westfalia-style hinged roof with canvas sides. The idea is, if the weather is bad we can close the canvas part and still do everything inside (except stand up straight). In the "down" mode for travel, it should be just a couple inches taller than the cab of the truck (Nissan Frontier 4-door short bed).

The building material is a honeycomb core with 2.7mm plywood skins (more on this later). I went with the plywood composite over a fiberglass composite primarily due to the fact that I'm building this in my garage and the thought of all that fiberglass dust all over everything was a deal breaker. Most of the camper exterior will then get a layer of fiberglass to give it some extra impact resistance. Aluminum angle is bonded on with 3m 5200 to protect/strengthen the outside corners. Joints are mostly butt joints - I fill the honeycomb with thickened epoxy and then clamp the joint together (usually overnight at least). The inside corners then get a fillet and 3" fiberglass tape. Outside corners get 6" tape where they don't get aluminum.

Since I don't have one of those cool 3-D graphics that others manage to do, you'll have to see the design unfold as it comes together.

The interior as it sits:

The interior is made of composites too, making the whole thing (hopefully) really strong. My floor plan prioritized getting the heavy stuff forward and including the "must-haves" that my girlfriend requested - inside shower, porta potty, 2-burner stove, fridge with freezer, battery-that-doesn't-go-dead-all-the-time, queen size bed with sit-up headroom, dinette seating, hot water, heater and, most importantly, "I don't want it to look home made". Well, that's a lot to cram in to a small camper and a tall order for someone with no experience in building this type of thing. Never mind, it's worth a try!

Lots or work yet to go. Currently working on getting the electrical, water and propane systems installed and still lots to do on painting and finishing construction of the roof.

Updates to follow!

matt