givemethewillys

Jonathan Chouinard

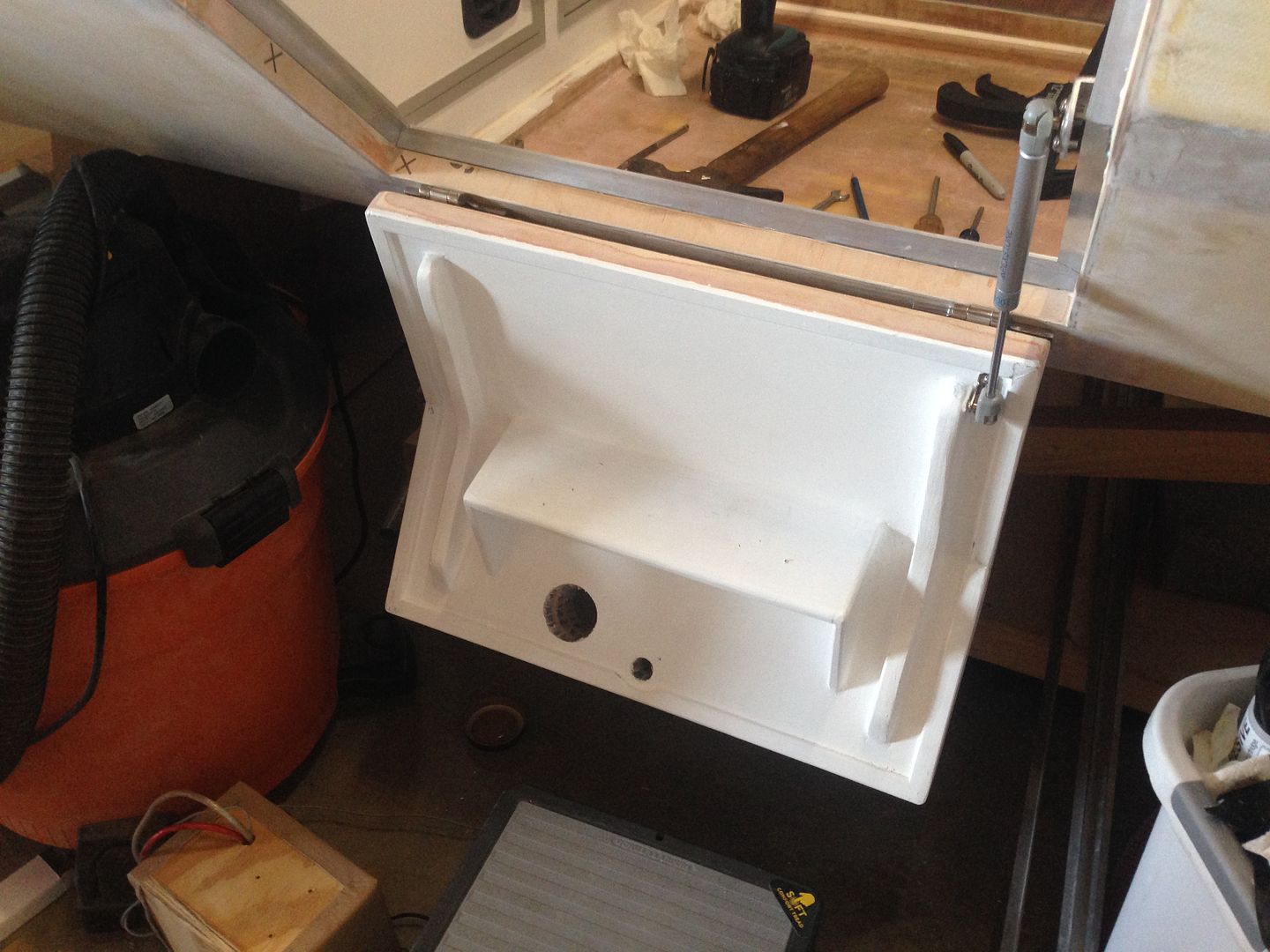

Your best bet might be to set up a vacuum bag for your countertop, that should make everything even and smooth.

Your best bet might be to set up a vacuum bag for your countertop, that should make everything even and smooth.

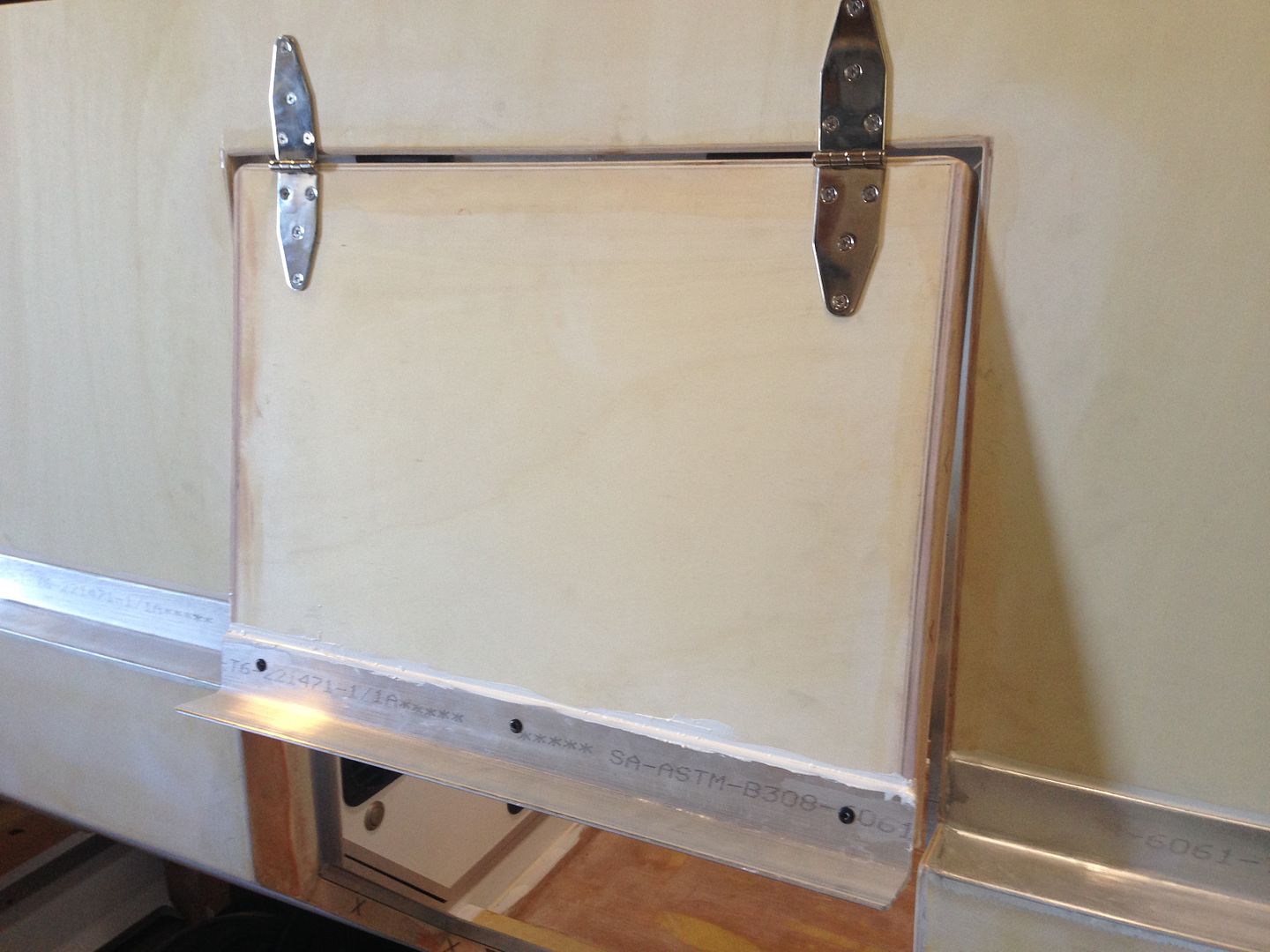

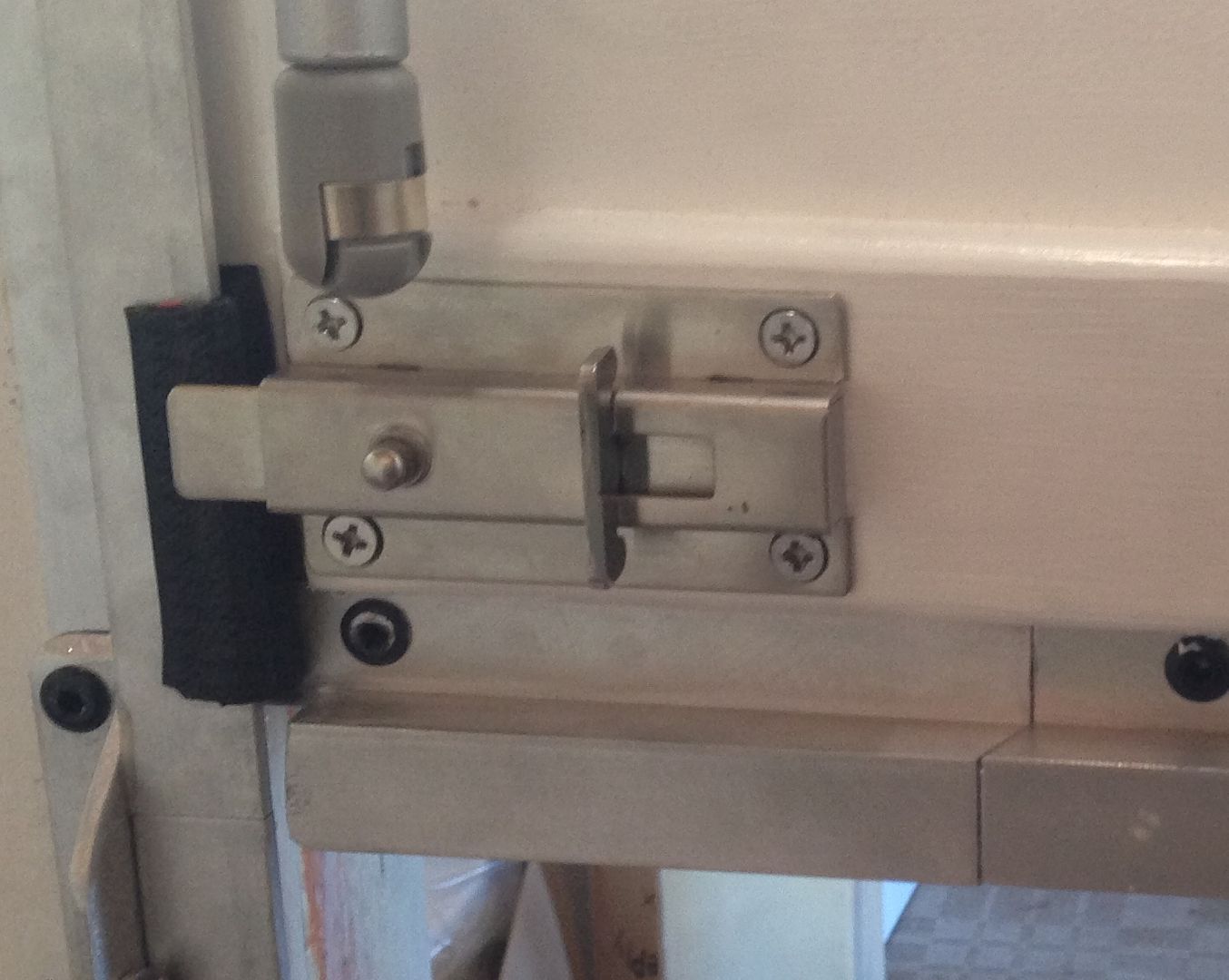

Can you tell me where you found those latches? I like how they secure. Great build!

You commented about Lithium. If you are going that way I would suggest the Sterling-Power BBW12180 DC to DC,it isn't cheap but it is marine grade waterproof. It will take 180amps of power and controls the voltage precisely for the chemistry, taking it up or down (most important for lithium) as modern alternators can toss some high voltages. Stick a 180 amp circuit breaker between it and the battery lead, you got to fuse it anyway, protects it and allows you to manually trip it if your alternator is getting hot. Lithium love amps and will put a huge strain on a stock alternator. You don't run into the same issues bulk charging Lipro so long run times aren't required in the same way. This was the route I was going until I dumped the Lipro for the FireFly. Expensive but...so is 200 Amp/hrs of Lipro and mixing automotive industry stuff... This is like pushing the easy button.

Yeah, that Sterling is a nice unit - but even the 60 amp version costs way more than my battery! Good choice if money is no object or you're protecting a big $$ bank - I'm looking towards a simpler yet effective approach. We'll see how it goes...

FireFly is interesting, but is the charging profile of your alternator correct for that chemistry? I know that it is in the lead-acid family, but not all lead-acid variants want to charge alike - gel batteries need a different charging profile than the common flooded lead acid (FLA) for instance or they can be damaged. FireFly info says bulk charge at 14.4v - that's lower than many modern alternators put out (as you noted). The impressive data they tout seems to all be from bench chargers (I assume programmed to the optimal voltages). How will they perform in the real world of alternators with bulk/absorption/float voltages engineered for FLA will be interesting to follow. I hope early adopters like yourself will track and post their experiences!

I know, in the same boat with my counter sunk locks and knob. Design is there just need to build it.The door is one of the few aspects of the project that I didn't give a lot of thought to before hand, thinking, I'll just figure something out. Kind of a relief that this approach seems to be working. So, on the the next thing...

I know, in the same boat with my counter sunk locks and knob. Design is there just need to build it.

Kevin

Looks great from over here.:sombrero::sombrero: