Bit of an emotional roller coaster last night. I was super excited to get my Advance Adapters TH400 -> NP205 adapter in, expecting it'd be the solve to my output/input shaft engagement concerns. To review, the stock 4WD 4L80e adapter, plus the Northwest Fab Works Circle-6 to Figure-8 adapter setup I was going to use leaves me with a bit more than 1.5" of overlap between the transmission output shaft and the transfer case input shaft. I felt like there should be more. In the mean time I'd found Advance Adapters has a reproduction TH400 -> NP205 adapter (these apparently are incredibly rare in the wild, so AA sells freshly cast ones). Thinking, "oh great, this'll just get ride of the 5/8-in. adapter from NFW and I'll be that much better off," I bought it. Well, it got delivered yesterday and like a kid at Christmas I tore open the box and ran down to the shop to try it out. Pretty quickly realized reality wasn't going to match expectations.

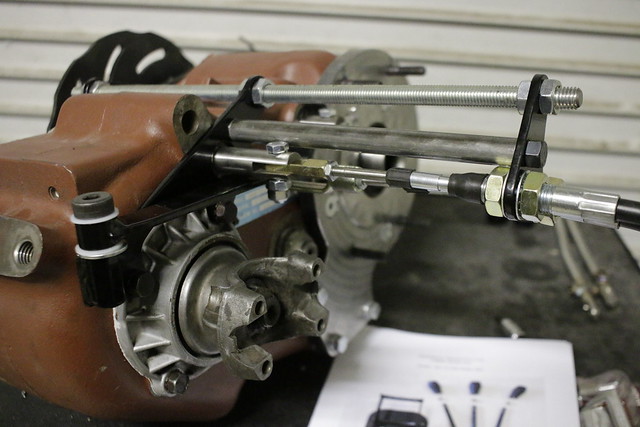

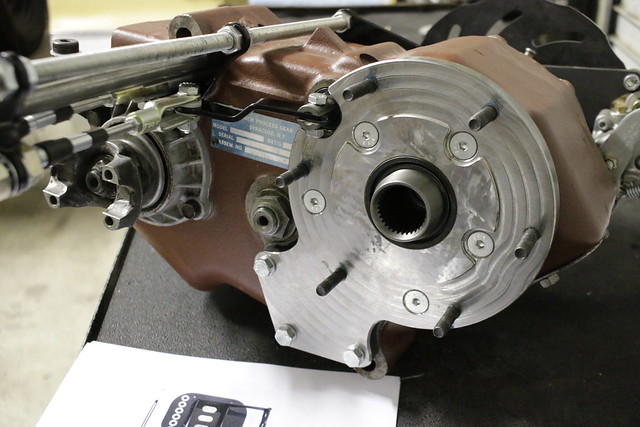

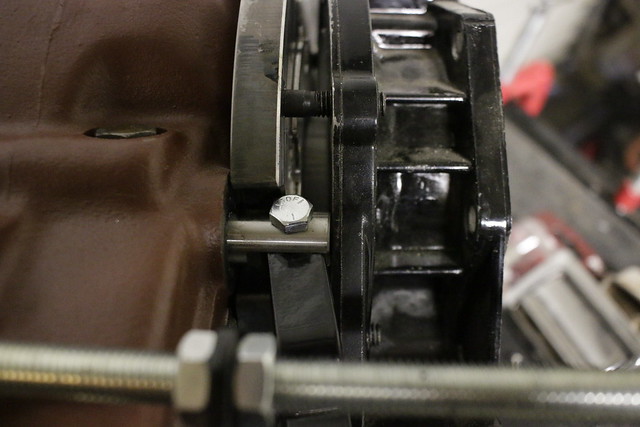

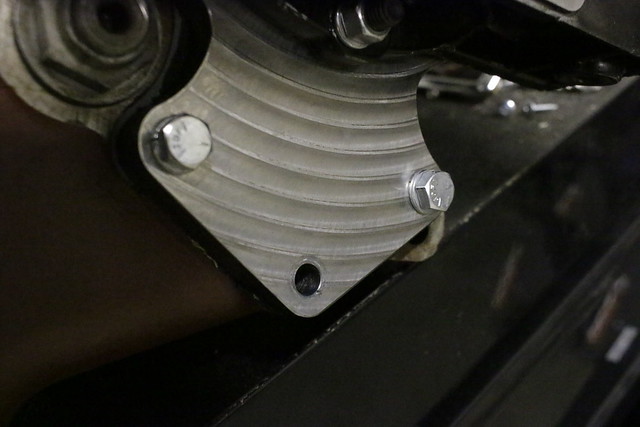

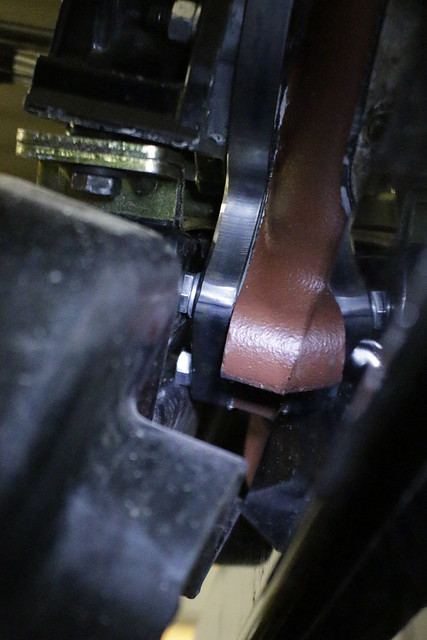

On the left you can see the stock 4wd 4L80e adapter plus the NFW bolt pattern adapter. On the right the TH400 -> NP205 adapter. You can see the problem. Just to confirm I loosely bolted up the AA adapter and sure enough, the output shaft doesn't even exit the adapter, and even with the input shaft now having an extra 5/8" from the mounting face on the NP205... I was calculating less than an inch of engagement between the two. What I hadn't read is that the full kit AA sells includes the

LONG NP205 input shaft. :squint: Read the details dumba**.

Fortunately Northwest Fab Works piped up in my Instagram when I mentioned them in the photo and confirmed that the short input shaft is what most of their customers run and they haven't heard of problems. After doing the math the long input shaft wouldn't even work with the stock adapter. So for now I'm gonna stick with this setup and return the AA adapter. Ultimately I'd like to get NFW's BlackBox underdrive, and this Circle-6 to Figure-8 is what is required to adapt an NP205 to that, and it mates to the 4L80e directly.

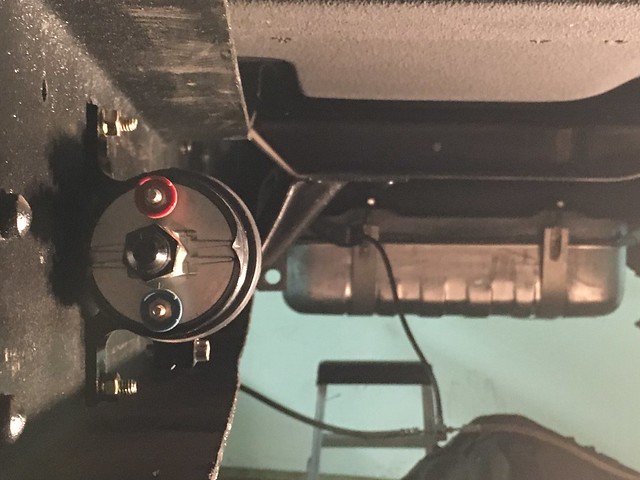

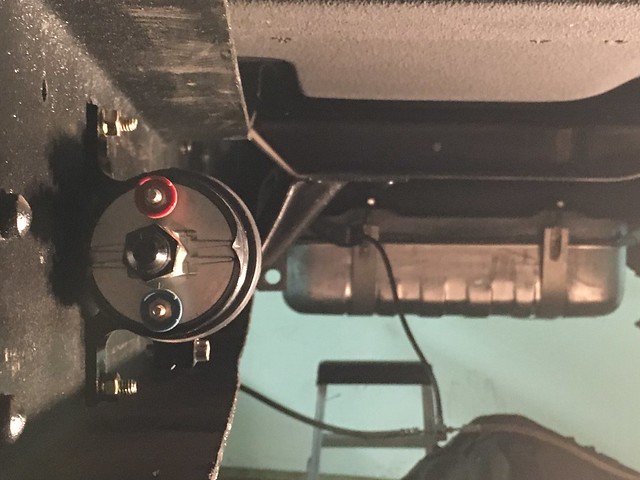

Another thing I checked off yesterday was mounting the fuel pump to the frame. As you can see from the picture the pump will end up being just above the bottom of the fuel tank. Between this placement and the Hydramat in the tank I'm feeling pretty good about things. With the pump installed I can start running fuel lines. I've been re-thinking having the fuel pressure regulator under the truck and looking at places I can put it in the engine bay. I've also picked up some hard line to run from the pump to the regulator since it is a pretty straight shot, and should only require a few bends to get up the firewall.

The truck's carpet gets here today, so I'll be picking that up and heading down to the shop again to lay that out to let it relax. Pretty excited to see how it looks! I've started painting the trim pieces with the Duplicolor Vinyl & Fabric paint, and they're looking great. Probably gonna focus on getting the doors finished so I can put them back on.

Oh! I also made a final decision about paint. I did a little cleaning of the truck the other day. Sitting in the shop for a year has gotten it pretty dusty and grimy. After getting all the gunk off I realized that the yellow paint is actually in pretty good shape. There's a few nicks and scratches here and there, but over all I think it is salvageable. SO... to start out I'm just going to clean and treat the problem rust and do the white in bed liner. I'm going to get the yellow parts professionally clayed and run it like that. This should be both cheap and easy, and cosmetically I think very good - keeping the original colors and protecting the lower part of the truck. As always I may completely change my mind in a week but I think after all the consideration I've done on bed liners and color matching and such, buffing the original back into shape is the idea that pleases me the most.