freshlikesushi

Free Candy

Need to work on your welding skills too.

Why? It holds. I'm not in a beauty contest

Thanks tho!

Need to work on your welding skills too.

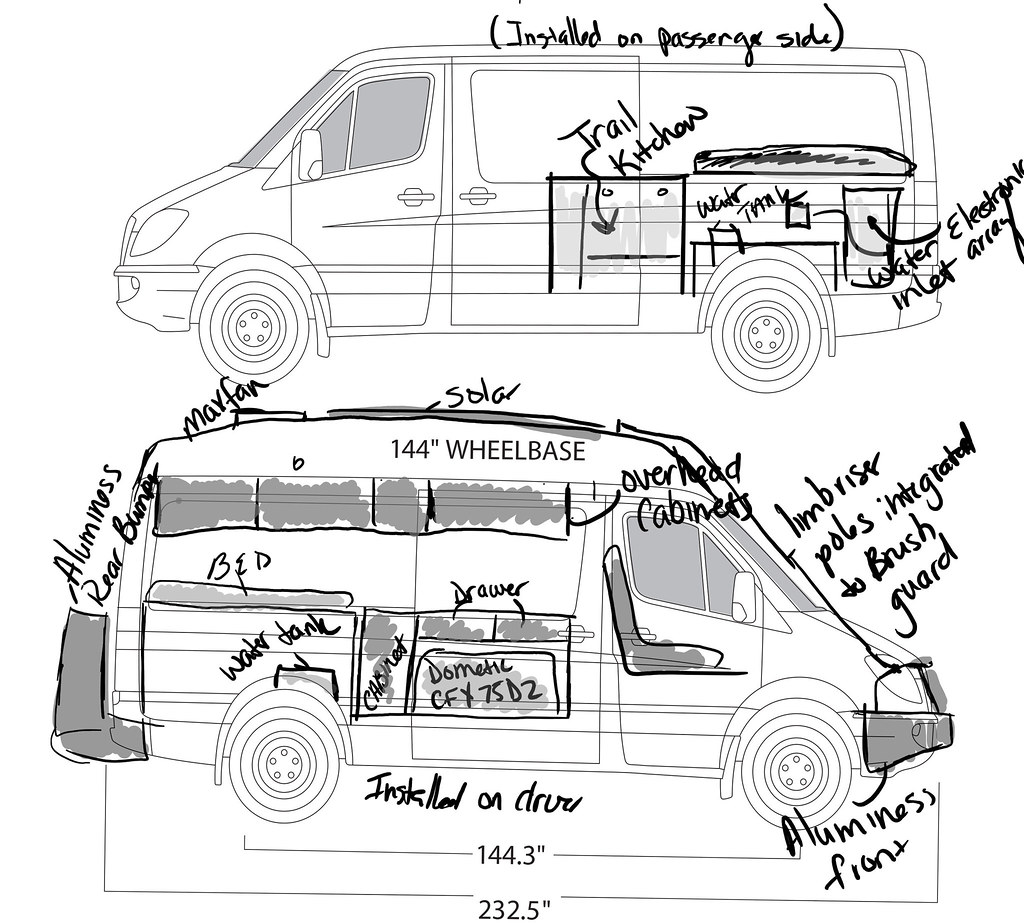

SprinterData144SideView by Grant Wilson, on Flickr

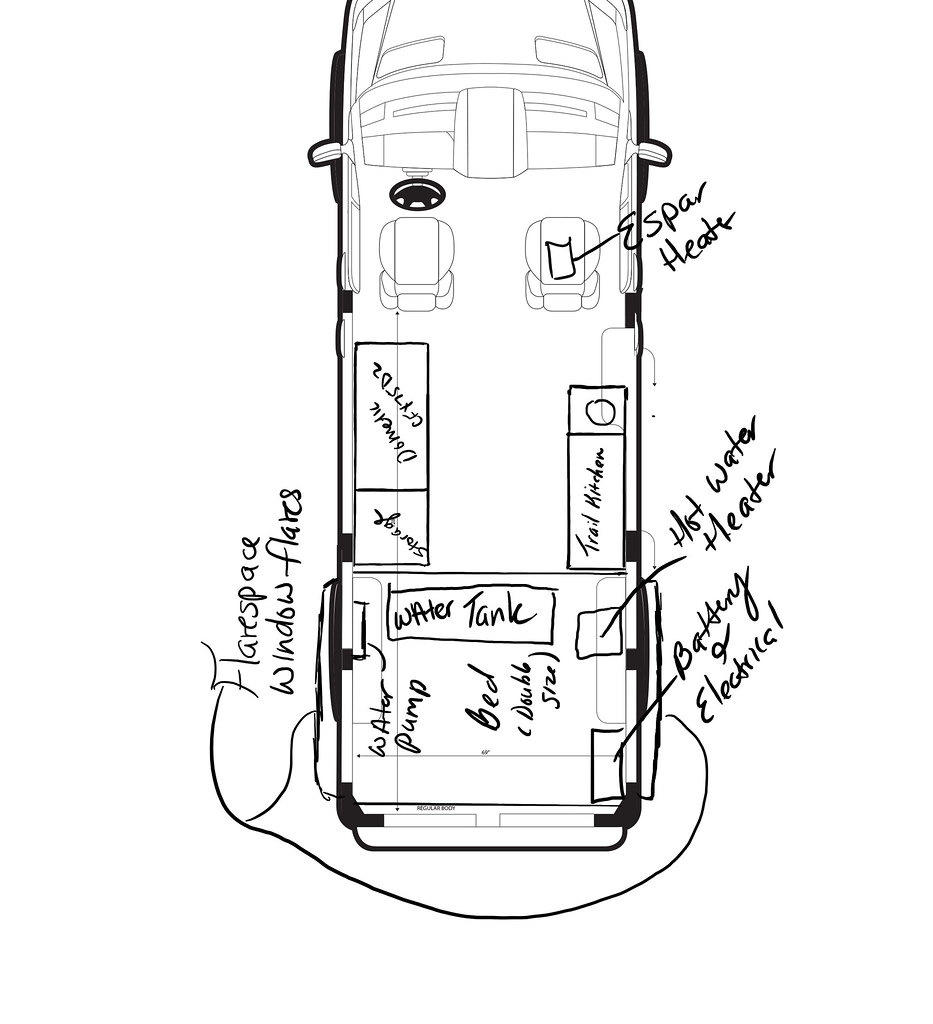

SprinterData144SideView by Grant Wilson, on Flickr OV_144_OVERHEAD_DRAWING_F by Grant Wilson, on Flickr

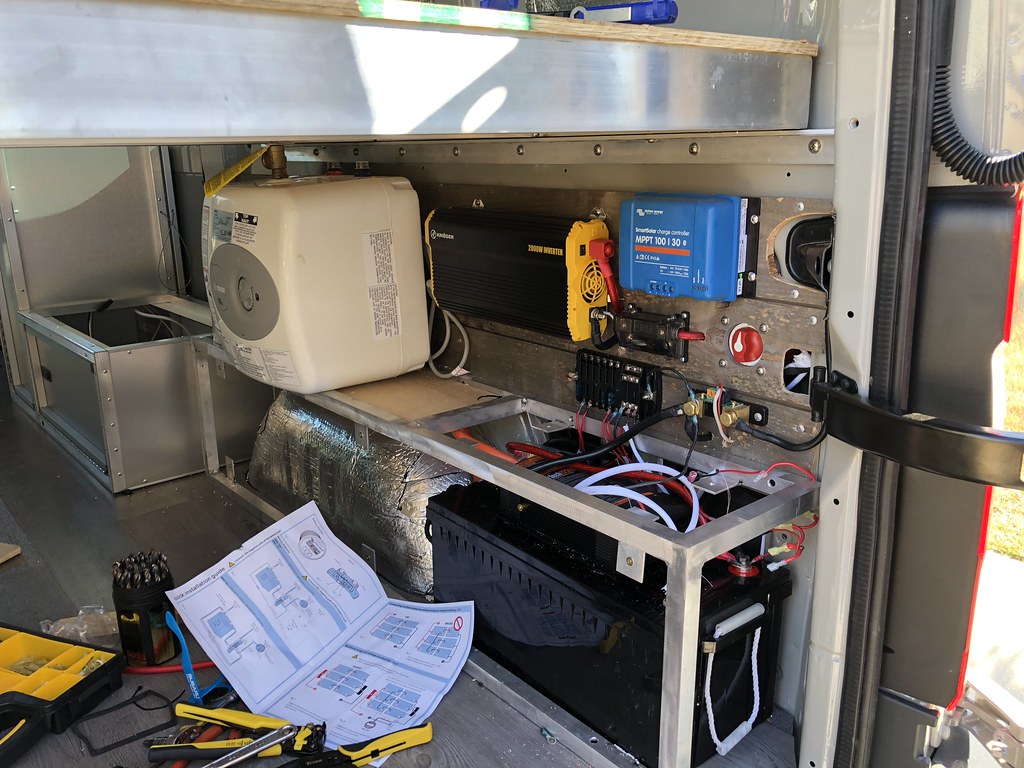

OV_144_OVERHEAD_DRAWING_F by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

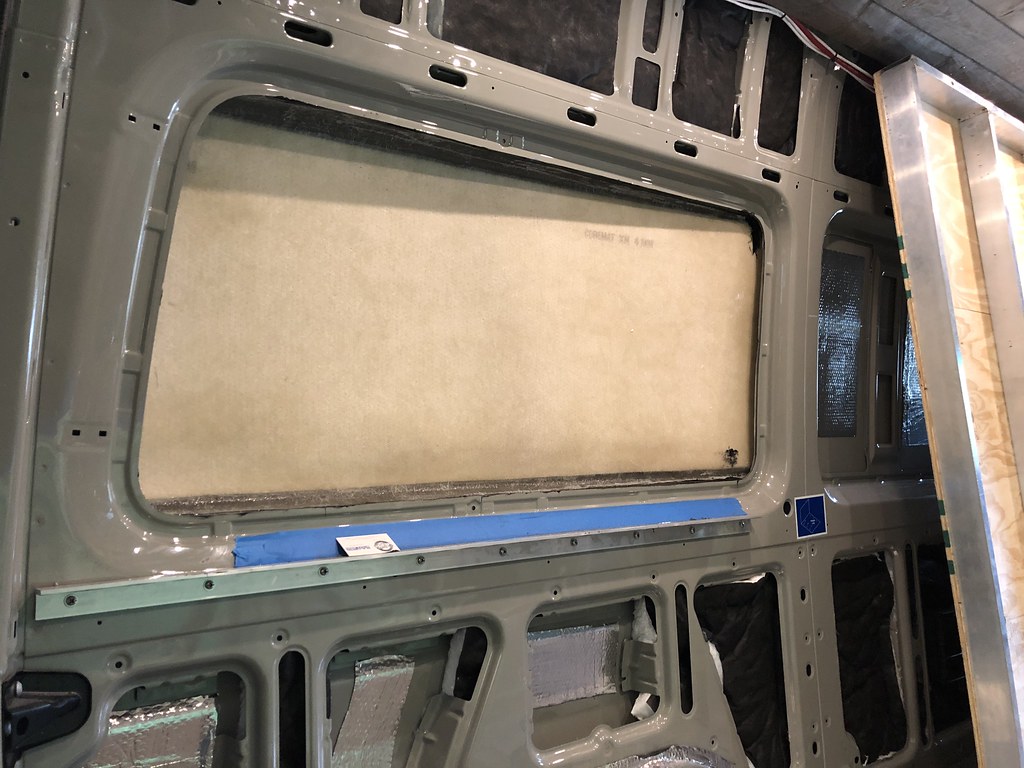

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr Untitled by Grant Wilson, on Flickr

Untitled by Grant Wilson, on Flickr