theREDwonder

Observer

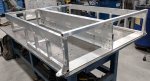

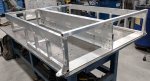

The culmination of way too much time on the computer and in the shop. As is customary, finished photo first:

I wanted a way to keep stuff organized in the back of the camper. With the Flippac, stuff was floating around everywhere and it was always a mess after a single night camping (wife + 1.5 year old daughter). This will hopefully help keep all the camper gear underneath and the clothes relegated to duffle bags.

I was inspired by this build, and even entertained the idea of buying it from him, now that it is for sale. I even looked at the decked system, but quickly balked at that after realizing that they are less than 45% efficient with the utilization of space. I have a friend with a full size truck and he loves them, they mid size truck iteration just wasn't doin it for me...and so I set off to design my own. I studied many builds, and thought about doing the ball bearing/tube sliders, but figured for the amount of money/time it would take to build, a set of drawer slides seems way easier/more robust. Using just wood seemed quick and dirty,

but also heavy. My good friend had great luck with a fabricated metal frame + purchased drawer + purchased slides, and this was the best route I chose to follow.

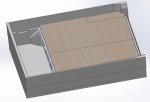

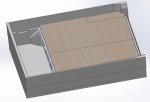

And so began the design:

I wanted the frame to slide in between the wheel wells while maximizing width and minimizing dead space. I came up with the idea of "stacking" the two center slides, and this saved a solid 2" of dead space. I was apprehensive about doing this because EVERY single drawer I've ever seen/ googled has both slides on the same plane. The engineer in me said its fine, and it turned out great. I almost went with a single giant drawer that would be have been cheaper and lighter (only 1 set of slides, and less frame), but I figured I need the center support to serve as our floor in the flippac.

Specs:

4'6" drawers on 4' lock in/ lock out slides.

Weight

* frame: 54 pounds

* 22.875" drawer: 32.3 pounds

* 17.250" drawer: 27.5 pounds

* 2x 48" 500 pound rated slides: 52 pounds total

* Plywood Floor: 45 pounds

* Mahogany Drawer Front: 5 pounds

* Hardware: 6 pounds

*Total: 221 pounds

It came out heavier than I wanted, but there really isnt that many more places I could cut weight.

Total money spent

* Drawer Slides from Orr & Orr: $270 + $60 shipping

* Drawers made by Drawer Box Specialities: $140 + $75 shipping

* Plywood: $50

* Mahogany: $20

* Carpet: $20

* Aluminum for frame: $175

* Hardware: $45

* Total: $855

I could have saved a bunch by picking up the drawers, they were only 100 miles away, but by the time you factor in gas and time, the shipping was worth it.

Being an engineer is a blessing and a curse. I spent way to long measuring/building the Taco bed in CAD, but that ultimately led to a product that fit the first time.

The drawers are 4' 6" long on 4' slides. This left an 18" full width cubby forward of the wheel wells. I plan to put a water tank in here.

I fabbed the frame at work during lunch over a few weeks, having all the right tools sure makes it go that much quicker and easier.

To keep the center "S" light, I used .125" wall C-Channel with a .25" welded in doubler. I then drilled the holes and installed stainless steel threaded inserts with a zinc chromate primer for corrosion prevention. The threaded insert install only took about 20 minutes, but not having to worry about aluminum threads galling or cross threading is worth the time.

Continued on...

I wanted a way to keep stuff organized in the back of the camper. With the Flippac, stuff was floating around everywhere and it was always a mess after a single night camping (wife + 1.5 year old daughter). This will hopefully help keep all the camper gear underneath and the clothes relegated to duffle bags.

I was inspired by this build, and even entertained the idea of buying it from him, now that it is for sale. I even looked at the decked system, but quickly balked at that after realizing that they are less than 45% efficient with the utilization of space. I have a friend with a full size truck and he loves them, they mid size truck iteration just wasn't doin it for me...and so I set off to design my own. I studied many builds, and thought about doing the ball bearing/tube sliders, but figured for the amount of money/time it would take to build, a set of drawer slides seems way easier/more robust. Using just wood seemed quick and dirty,

but also heavy. My good friend had great luck with a fabricated metal frame + purchased drawer + purchased slides, and this was the best route I chose to follow.

And so began the design:

I wanted the frame to slide in between the wheel wells while maximizing width and minimizing dead space. I came up with the idea of "stacking" the two center slides, and this saved a solid 2" of dead space. I was apprehensive about doing this because EVERY single drawer I've ever seen/ googled has both slides on the same plane. The engineer in me said its fine, and it turned out great. I almost went with a single giant drawer that would be have been cheaper and lighter (only 1 set of slides, and less frame), but I figured I need the center support to serve as our floor in the flippac.

Specs:

4'6" drawers on 4' lock in/ lock out slides.

Weight

* frame: 54 pounds

* 22.875" drawer: 32.3 pounds

* 17.250" drawer: 27.5 pounds

* 2x 48" 500 pound rated slides: 52 pounds total

* Plywood Floor: 45 pounds

* Mahogany Drawer Front: 5 pounds

* Hardware: 6 pounds

*Total: 221 pounds

It came out heavier than I wanted, but there really isnt that many more places I could cut weight.

Total money spent

* Drawer Slides from Orr & Orr: $270 + $60 shipping

* Drawers made by Drawer Box Specialities: $140 + $75 shipping

* Plywood: $50

* Mahogany: $20

* Carpet: $20

* Aluminum for frame: $175

* Hardware: $45

* Total: $855

I could have saved a bunch by picking up the drawers, they were only 100 miles away, but by the time you factor in gas and time, the shipping was worth it.

Being an engineer is a blessing and a curse. I spent way to long measuring/building the Taco bed in CAD, but that ultimately led to a product that fit the first time.

The drawers are 4' 6" long on 4' slides. This left an 18" full width cubby forward of the wheel wells. I plan to put a water tank in here.

I fabbed the frame at work during lunch over a few weeks, having all the right tools sure makes it go that much quicker and easier.

To keep the center "S" light, I used .125" wall C-Channel with a .25" welded in doubler. I then drilled the holes and installed stainless steel threaded inserts with a zinc chromate primer for corrosion prevention. The threaded insert install only took about 20 minutes, but not having to worry about aluminum threads galling or cross threading is worth the time.

Continued on...

Last edited: