You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2-2.5" of lift, are cam bolts really that bad?

- Thread starter kojackJKU

- Start date

brianjwilson

Some sort of lost...

I wouldn't use them myself. As is, the lower control arm mount on the axle has a square hole that the bolt loosely fits into. A cam bolt setup will require that hole to be opened up more, although the cam washer should in theory keep the bolt in place. Thing is, the front lower control arms take the brunt of every bump, dip, braking action etc and the washers can easily move around.

I would, first, strongly recommend a full suspension bolt kit from synergy or northridge4x4. They will replace the bolts in the control arms and track bars with bolts that are the proper size and shouldered versus the undersized bolts from the factory that are threaded full length. This firms everything up, and helps prevent damage to the bushing sleeves and ovaling out the mounting holes. You should use cam eleminator washers the keep those lower front bolts centered. If the kit you purchase doesn't include some, get them.

For caster you can either purchase adjustable lower control arms and fine tune, order fixed (slightly longer) lower control arms, or check out the AEV geometry correction brackets. They will lower the frame side lower arms about 2" which in itself will help the way the suspension absorbs hits, but the upper arms are lowered further which improves the geometry and reduces brake dive. They also set caster around 4-4.5 degrees (not adjustable).

I would, first, strongly recommend a full suspension bolt kit from synergy or northridge4x4. They will replace the bolts in the control arms and track bars with bolts that are the proper size and shouldered versus the undersized bolts from the factory that are threaded full length. This firms everything up, and helps prevent damage to the bushing sleeves and ovaling out the mounting holes. You should use cam eleminator washers the keep those lower front bolts centered. If the kit you purchase doesn't include some, get them.

For caster you can either purchase adjustable lower control arms and fine tune, order fixed (slightly longer) lower control arms, or check out the AEV geometry correction brackets. They will lower the frame side lower arms about 2" which in itself will help the way the suspension absorbs hits, but the upper arms are lowered further which improves the geometry and reduces brake dive. They also set caster around 4-4.5 degrees (not adjustable).

Ok,

I am still using stock parts, I just find my steering a little flighty since my teraflex leveling kit. Maybe its just me. or maybe its the tires. The drop brackets are not useable with my leveling kit.

Will the hardware upgrade tighten everything up even if stock? Im fine with my stance now, actually it sits perfect. I will be taking out my stock springs and adding something else for extra weight but im going to try to stay close to my height now.

I am still using stock parts, I just find my steering a little flighty since my teraflex leveling kit. Maybe its just me. or maybe its the tires. The drop brackets are not useable with my leveling kit.

Will the hardware upgrade tighten everything up even if stock? Im fine with my stance now, actually it sits perfect. I will be taking out my stock springs and adding something else for extra weight but im going to try to stay close to my height now.

NFRs2000NYC

Adventurer

I recommend the rancho drop brackets. They are better designed (stronger) than AEV brackets. The ride on my jeep is spectacular.

315s on an AEV 2.5" (with modifications)

Look at how the control arm sits, perfectly parallel to the ground.

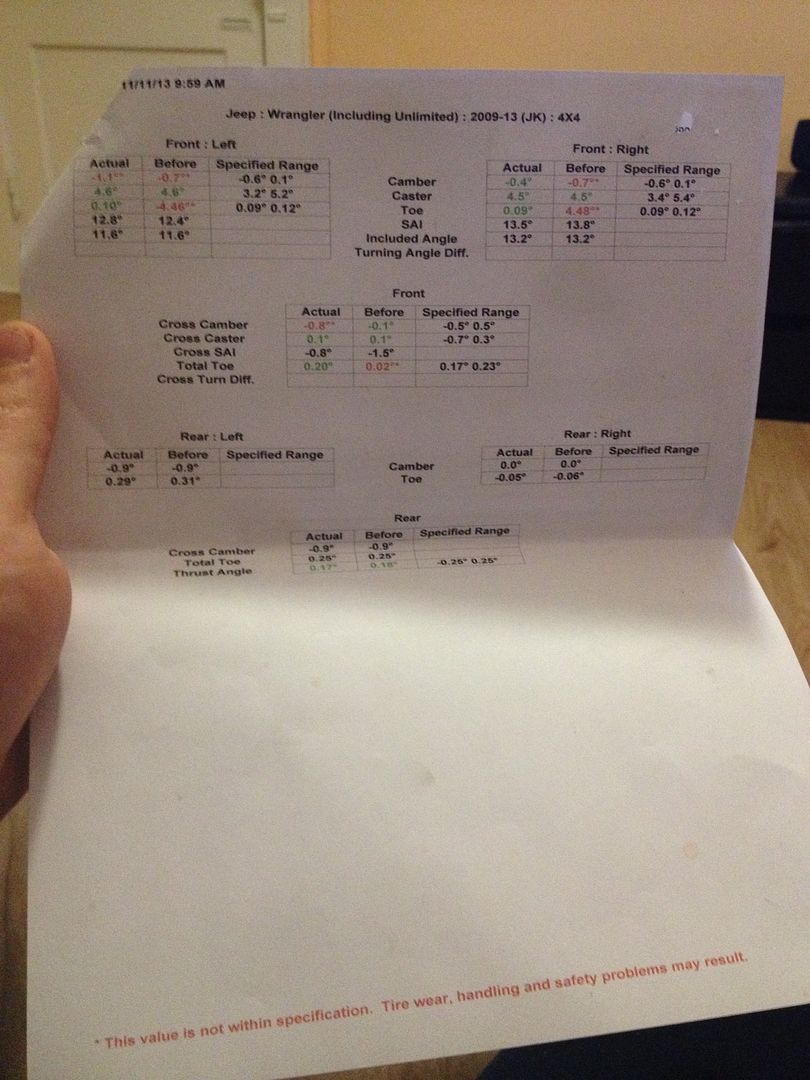

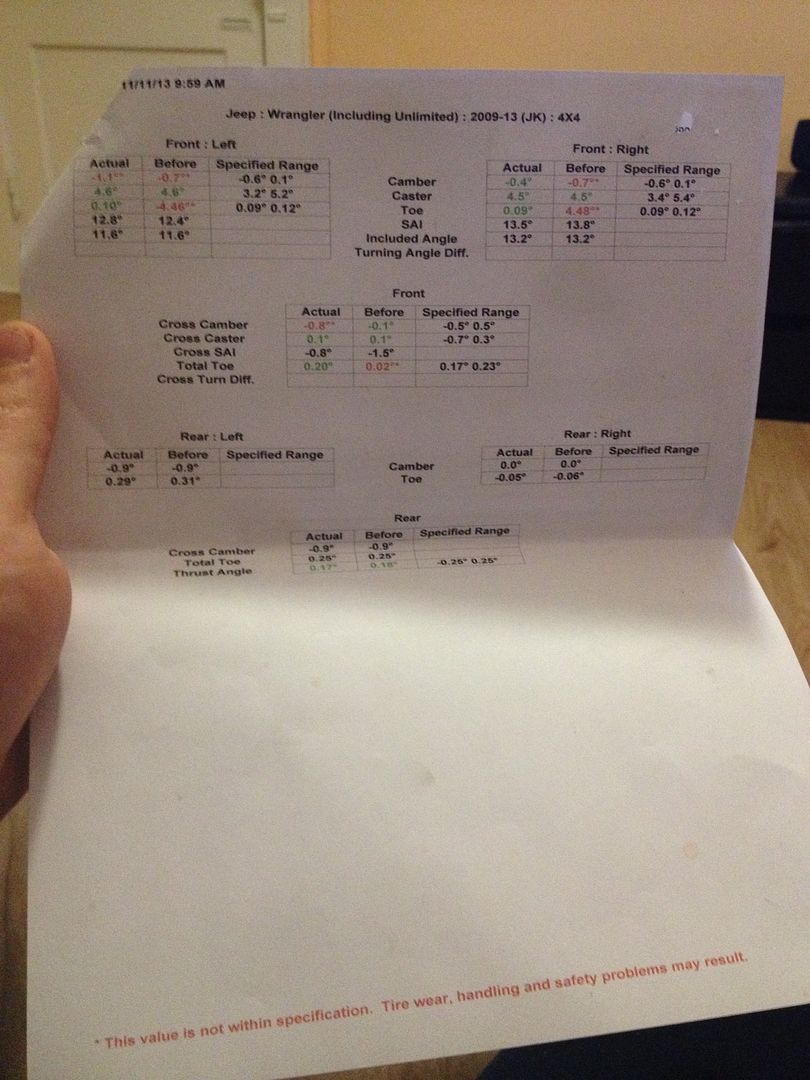

And the pudding....alignment is PERFECT dead on (4.5)

Stay away from cambolts.

315s on an AEV 2.5" (with modifications)

Look at how the control arm sits, perfectly parallel to the ground.

And the pudding....alignment is PERFECT dead on (4.5)

Stay away from cambolts.

brianjwilson

Some sort of lost...

Either of the brackets will work. All they move is the control arm mounts on the frame side.

Just my two cents, it appears that the rancho brackets hang down a little further, I could be wrong. AEB has revised theirs so the left and right brackets bolt together for more strength. I have the older version, I've drug mine over rocks a handful of times and never damaged anything, just scraped the paint on the control arms and bottom of the brackets. Also, I'm unsure about the rancho brackets, but the AEV brackets actually improve on factory geometry. The upper mounts are dropped probably twice as far which changes the way the axle rotates through its range of motion. Not only decreasing brake dive but also helping tilt the pinion up when the axle droops. This helps the driveshaft last longer and reduces driveline angles.

Again I don't know if the rancho brackets do that or if they are simple drop brackets. The pictures I'm seeing online look like they drop the uppers and lowers an equal amount, just basic drop brackets. AEVs suspension guys are former jeep/Chrysler engineers and focus on improving, not just correcting, geometry.

Just my two cents, it appears that the rancho brackets hang down a little further, I could be wrong. AEB has revised theirs so the left and right brackets bolt together for more strength. I have the older version, I've drug mine over rocks a handful of times and never damaged anything, just scraped the paint on the control arms and bottom of the brackets. Also, I'm unsure about the rancho brackets, but the AEV brackets actually improve on factory geometry. The upper mounts are dropped probably twice as far which changes the way the axle rotates through its range of motion. Not only decreasing brake dive but also helping tilt the pinion up when the axle droops. This helps the driveshaft last longer and reduces driveline angles.

Again I don't know if the rancho brackets do that or if they are simple drop brackets. The pictures I'm seeing online look like they drop the uppers and lowers an equal amount, just basic drop brackets. AEVs suspension guys are former jeep/Chrysler engineers and focus on improving, not just correcting, geometry.

1stDeuce

Explorer

It's probably worth noting that there's nothing wrong with cam bolts themselves, as TJ's, ZJ's, WJ's, etc used the for years. I think the problem on a JK is that it isn't really fully designed for cam bolts... You have to slot the axle bracket to allow the bolt to actually travel, and lots of places seem to hog them out way too big. That leaves little of the bracket for the sleeve to engage, and they come loose. It's just a PITA basically. I've seen a stamp tool for doing it, but I don't know how well it works. Hmm. We have a JK axle at work... I'll have to check it out tomorrow. We have the stamp tool too, so I'll let you know how it works as well!

Contrary to popular belief, the actual fit of the bolt in the bushing sleeve/mounting hole should NEVER come into play. The clamp load that the bolt places through the bushing sleeve is what holds things in place. The ones I've seen have problems look like a 300lb drunk idiot opened them up with a 1" drill bit or something... The same bolt kit that fits JK fits other dodge vehicles IIRC, and they don't have problems. Even 1-ton dodge trucks used lower cam bolts and they didn't have problems. ??

On the plus side, for 2-2 1/2" lift, you really shouldn't need cam bolts anyway. Another thing that may sway you is that adding caster can sometimes exacerbate a death wobble condition if your Jeep happens to be borderline. (And all JK's are...)

Good Luck!

Chris

Contrary to popular belief, the actual fit of the bolt in the bushing sleeve/mounting hole should NEVER come into play. The clamp load that the bolt places through the bushing sleeve is what holds things in place. The ones I've seen have problems look like a 300lb drunk idiot opened them up with a 1" drill bit or something... The same bolt kit that fits JK fits other dodge vehicles IIRC, and they don't have problems. Even 1-ton dodge trucks used lower cam bolts and they didn't have problems. ??

On the plus side, for 2-2 1/2" lift, you really shouldn't need cam bolts anyway. Another thing that may sway you is that adding caster can sometimes exacerbate a death wobble condition if your Jeep happens to be borderline. (And all JK's are...)

Good Luck!

Chris

brianjwilson

Some sort of lost...

It's probably worth noting that there's nothing wrong with cam bolts themselves, as TJ's, ZJ's, WJ's, etc used the for years. I think the problem on a JK is that it isn't really fully designed for cam bolts... You have to slot the axle bracket to allow the bolt to actually travel, and lots of places seem to hog them out way too big. That leaves little of the bracket for the sleeve to engage, and they come loose. It's just a PITA basically. I've seen a stamp tool for doing it, but I don't know how well it works. Hmm. We have a JK axle at work... I'll have to check it out tomorrow. We have the stamp tool too, so I'll let you know how it works as well!

Contrary to popular belief, the actual fit of the bolt in the bushing sleeve/mounting hole should NEVER come into play. The clamp load that the bolt places through the bushing sleeve is what holds things in place. The ones I've seen have problems look like a 300lb drunk idiot opened them up with a 1" drill bit or something... The same bolt kit that fits JK fits other dodge vehicles IIRC, and they don't have problems. Even 1-ton dodge trucks used lower cam bolts and they didn't have problems. ??

On the plus side, for 2-2 1/2" lift, you really shouldn't need cam bolts anyway. Another thing that may sway you is that adding caster can sometimes exacerbate a death wobble condition if your Jeep happens to be borderline. (And all JK's are...)

Good Luck!

Chris

The bolts passing through the bushing sleeves shouldn't come into play, but they do. Evidence on SO many JKs (including mine that was frequently torqued properly) proves that it is an issue.

aristobrat

Observer

FWIW, check out AEV's install guide, ... it's just a 3-page PDF. The last page has a quick test you can do to verify that the brackets will be OK with your JK. It basically just has to do with the distance between the bottom of the frame to the top of the spring seat. They have it illustrated.yeah, I am going to. Those brackets won't work with my leveling kit however, correct?

http://www.aev-conversions.com/isheets/aev_drop_brackets.pdf

Also, I've never run the Rancho brackets, but like brian mentioned, the AEV brackets are different from the Rancho in that AEV drops the upper control arms even more than the lower arms are dropped, which adds some additional positive characteristics.