dustboy

Explorer

The madness begins

Well, it's beginning. This will either be the dumbest thing I've ever done, or the coolest.

I scored 5 nice clean 10' sticks of 14 ga 2x2 box from the scrap yard, and 4 10' sticks of 12 ga 2x2 angle iron. Altogether they weigh about 175 lbs, I'm hoping this flatbed will be at least as light as the factory bed plus my current sleeping platform..always optimistic.

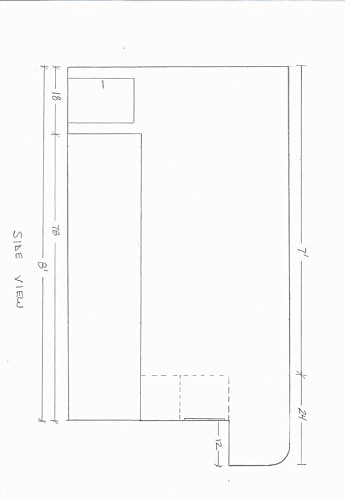

To start I cleared some floor space in my tiny garage. Next step was to lay out the perimeter of the top of the bed. This thing will be built upside down, since I need a flat plane to start from. The bed will be 80" x 64".

The floor of my garage is FAR from flat, so to get a proper start to the project, I carefully laid out the pieces and used a level to get them all in the same plane, putting pieces of whatever was laying around to prop them at the right height.

Next I tacked the outside corners together. My crappy saw cuts miters at just a hair over 45*, which is actually good because when you lay out a square like this, all the outside corners will touch.

Since only the outside corners are tacked, the whole frame can now be squared. This is easily done by measuring diagonally across the corners, when the two measurements match, the frame is square.

Once everything is perfect, I tack welded all the corners so the frame can't move, and it's ready to do the final welds. That's as far as I got last night, my buddy called with tickets to the Supercross race, so the rest of the night was smuggled margaritas, dirtbikes and pyrotechnics.

Well, it's beginning. This will either be the dumbest thing I've ever done, or the coolest.

I scored 5 nice clean 10' sticks of 14 ga 2x2 box from the scrap yard, and 4 10' sticks of 12 ga 2x2 angle iron. Altogether they weigh about 175 lbs, I'm hoping this flatbed will be at least as light as the factory bed plus my current sleeping platform..always optimistic.

To start I cleared some floor space in my tiny garage. Next step was to lay out the perimeter of the top of the bed. This thing will be built upside down, since I need a flat plane to start from. The bed will be 80" x 64".

The floor of my garage is FAR from flat, so to get a proper start to the project, I carefully laid out the pieces and used a level to get them all in the same plane, putting pieces of whatever was laying around to prop them at the right height.

Next I tacked the outside corners together. My crappy saw cuts miters at just a hair over 45*, which is actually good because when you lay out a square like this, all the outside corners will touch.

Since only the outside corners are tacked, the whole frame can now be squared. This is easily done by measuring diagonally across the corners, when the two measurements match, the frame is square.

Once everything is perfect, I tack welded all the corners so the frame can't move, and it's ready to do the final welds. That's as far as I got last night, my buddy called with tickets to the Supercross race, so the rest of the night was smuggled margaritas, dirtbikes and pyrotechnics.