jscherb

Expedition Leader

My career had nothing to do with fabrication, this is just a hobby for me....You are killing me here with all this stuff! I can't even draw it in mspaint, and you just go out and build it like legos! If you don't mind me asking, what do you do for a living, is all this fab part of your day-to-day? I can't even fathom what you must have wrapped up ($) in all your projects!

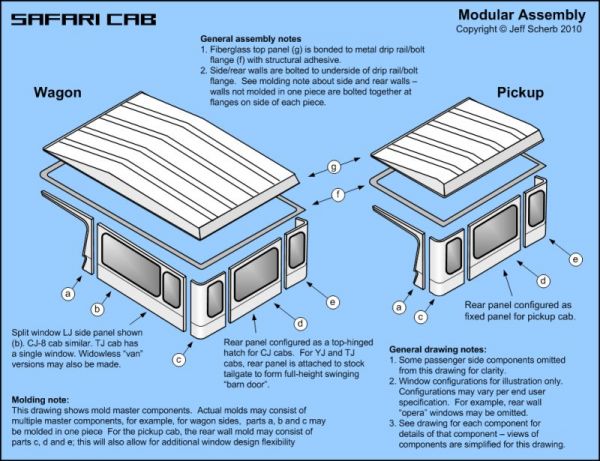

It costs about $500-600 for the materials to mold one of these LJ tops, so it's not too expensive. Building the molds cost a bit more than that, but the biggest investment is time, not materials.

Last edited: