saburai

Explorer

Hi Gang!

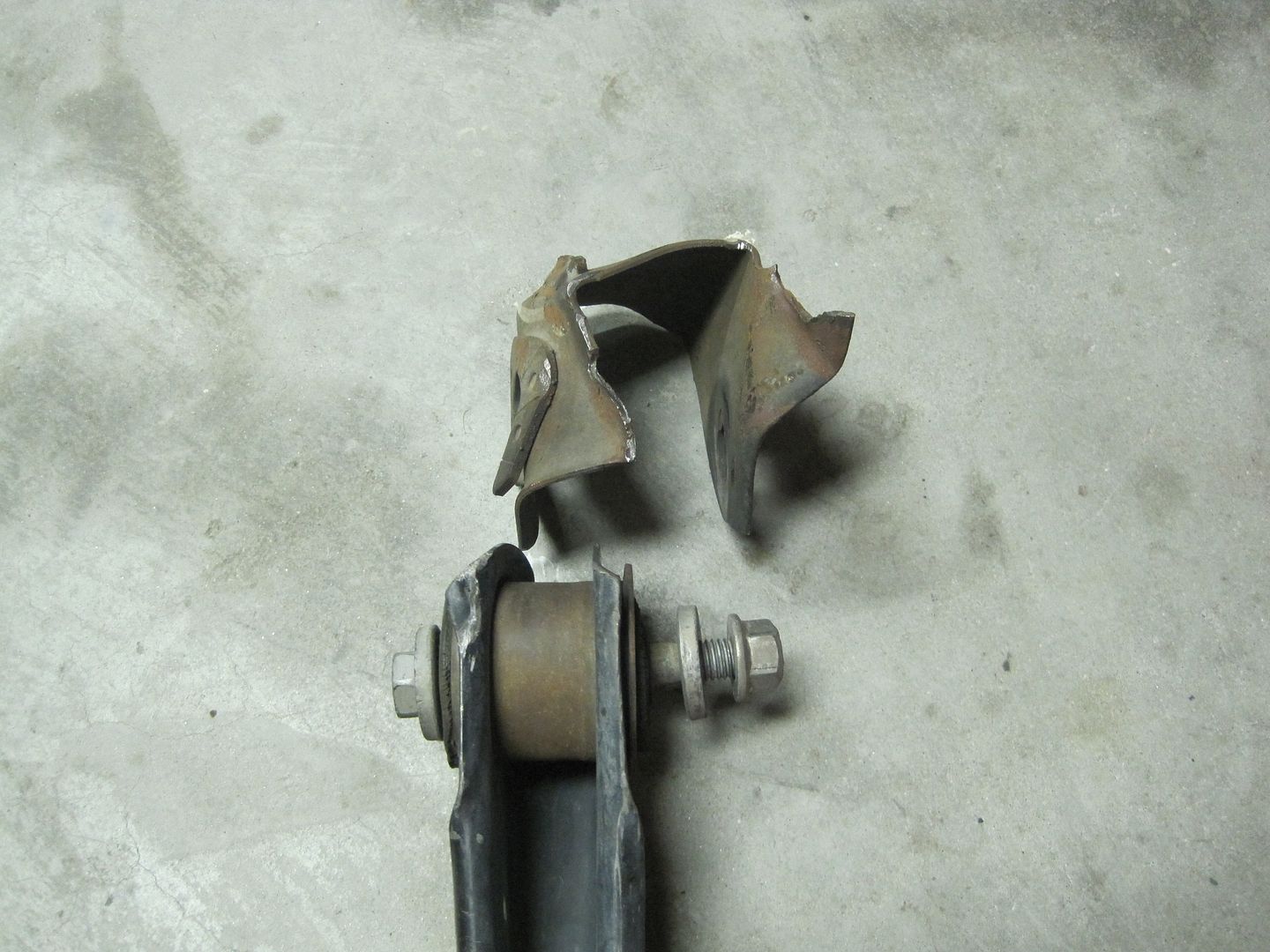

The other day I was out playing around and managed to bash, at a very slow speed my passenger side lower control arm mount. I whacked it hard enough to bend it a good bit. There is no noticeable change driving the truck over the road. I'm wondering what my best course of action would be. I'm thinking that I should take it apart and bend it back and then install some skid row LCA plates, here's a link:

http://www.skidplates.com/LCA_Plates.asp

They look pretty beefy and I think if I had had them on there before I took the hit, I wouldn't be writing this post...

Input, thoughts and suggestions please!

The other day I was out playing around and managed to bash, at a very slow speed my passenger side lower control arm mount. I whacked it hard enough to bend it a good bit. There is no noticeable change driving the truck over the road. I'm wondering what my best course of action would be. I'm thinking that I should take it apart and bend it back and then install some skid row LCA plates, here's a link:

http://www.skidplates.com/LCA_Plates.asp

They look pretty beefy and I think if I had had them on there before I took the hit, I wouldn't be writing this post...

Input, thoughts and suggestions please!