Hello FlyFishermen:

There are a lot of different rope shackles out there and they differ in how the shackle portion and the end knot are tied. I found some tests of the various styles (I can't find the link) and decided to use the "High Strength Soft Shackle" (

http://l-36.com/high_strength_soft_shackle.php) with the "Button Knot" instead of the "Diamond Knot". It is a an easy shackle to make, but the Button Knot is definitely the hard part (or it was for me). I found a good description of the Button Knot at

http://www.bethandevans.com/pdf/button.pdf that finally allowed me to tie one. It takes a lot of time to work the button knot into the rock hard form you want, but I sit in front of the TV and work at it bit by bit. I also found it helpful to mount the two lines in a vice as I laid out the Button Knot. The next time I do the Button Knot on a soft shackle I plan to mark one of the lines with a black Marks Alot to keep the two strands identifiable.

The only other thing I found that wasn't well described in the instructions was that you want the closable loop in the end of the shackle opposite the knot to be as small as possible. I thought that since that loop closes around the knotted end of the shackle as the shackle is weighted that it would close up completely regardless of it's size. That is only partially true. If you leave it bigger than "as small as you can make it" the weighted shackle has some space around the knotted end that looks like it could increase the chance of the weighted shackle opening. I've not seen one open under load, so my preoccupation could be baseless, but if you make the loop as small as you can, the weighted shackle closes up nicer and inspires more confidence.

To figure out the length of line to use for the shackle, I use the online calculator here (

http://l-36.com/soft_shackle_9.php). Even though that calculator occurs on page describing a different shackle, it does a fair job of estimating the length for the "High Strength Soft Shackle."

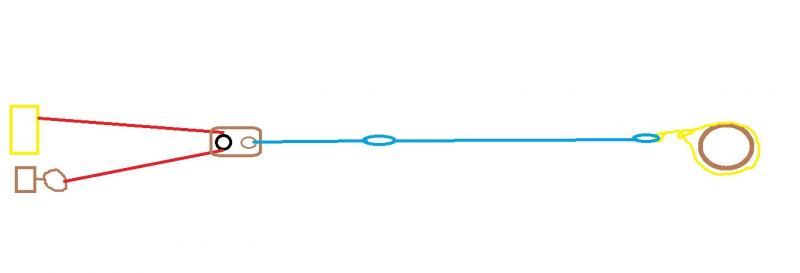

I use 2" tubular webbing as a partial chafe guard on the soft shackle. I'd prefer 3" tubular webbing so that the chafe guard would cover the whole length, but I could fine 3" tubular.

Some additional information that might be useful. I wasn't satisfied with the bulk and expense of the various static line or webbing "tree slings" (lifting slings in the crane lingo) available. I made my own by splicing Amsteel Blue into a closed loop (a circle). I then flattened the circle and passed it through a piece of 2" tubular webbing. Before splicing I had placed other stripes of webbing onto the line so that the final sling had chafe guards at each end with the middle contained in the 2" tubular webbing. I'm not sure this description makes any sense - so if you're interested in that configuration, let me know and I'll take a photograph.

Finally - if you use soft shackles I think it is really important to make sure that everything is your set up is absolutely static. If you have any dynamic components in the system they will stretch and build up energy that could case flying lines if anything gives way. As long as everything is static then there is much less potential energy and if something breaks you don't have flying pieces going around to break windshields, arms or heads!

Howard