1x1_Speed_Craig

Active member

Hi all,

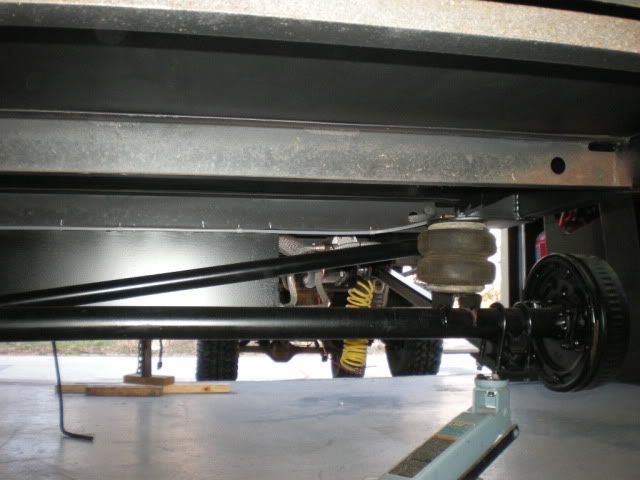

I'm just finalizing an order with Martyn at AT for some Firestone air bags and upper mounting brackets, among several other things.

I'll be using the air bags for the suspension, and will main leafs from a set of new stock CJ-7 front springs to locate the axle only (I also plan on adding shocks). I also have CJ-7 main eye hangers and shackle mounts, but am open to doing something different if needed (read on...).

I have seen several people suggest using the "dummy" leaf spring to locate the axle, but have not been able to find any photos of such a set-up.

Does anyone have pics of a trailer running this air bag/leaf spring combo?

I mainly wondered about the following:

Any ideas, thoughts, and most of all PHOTOS are greatly appreciated.

Thanks,

Craig

I'm just finalizing an order with Martyn at AT for some Firestone air bags and upper mounting brackets, among several other things.

I'll be using the air bags for the suspension, and will main leafs from a set of new stock CJ-7 front springs to locate the axle only (I also plan on adding shocks). I also have CJ-7 main eye hangers and shackle mounts, but am open to doing something different if needed (read on...).

I have seen several people suggest using the "dummy" leaf spring to locate the axle, but have not been able to find any photos of such a set-up.

Does anyone have pics of a trailer running this air bag/leaf spring combo?

I mainly wondered about the following:

- With a 2" budget boost and 31" BFG KM2s on my tow vehicle (and trailer), I planned on running spring-under on the trailer to best match the ride height. I may have to run spring-over to allow the air springs enough space for the full range of travel. I'm also wondering if the stock-height leaves will be adequate.

- I'm wondering about clearance for the air bag diameter (mounted just inboard of the frame rail) between the leaf spring/U-bolt spring plate/etc. when compressed.

Any ideas, thoughts, and most of all PHOTOS are greatly appreciated.

Thanks,

Craig