It is time to import my trailer build into expedition portal. I finished principle construction of this trailer in 2012 and have been using it since. At this point the main thing missing (and the primary reason for this thread) is a well thought out kitchen setup. I have been working out of crates or plastic totes to this point which has worked out so far, but my trips to date have all been relatively short (seven days or less). In planning for longer trips the advantage of something better thought out becomes more and more obvious.

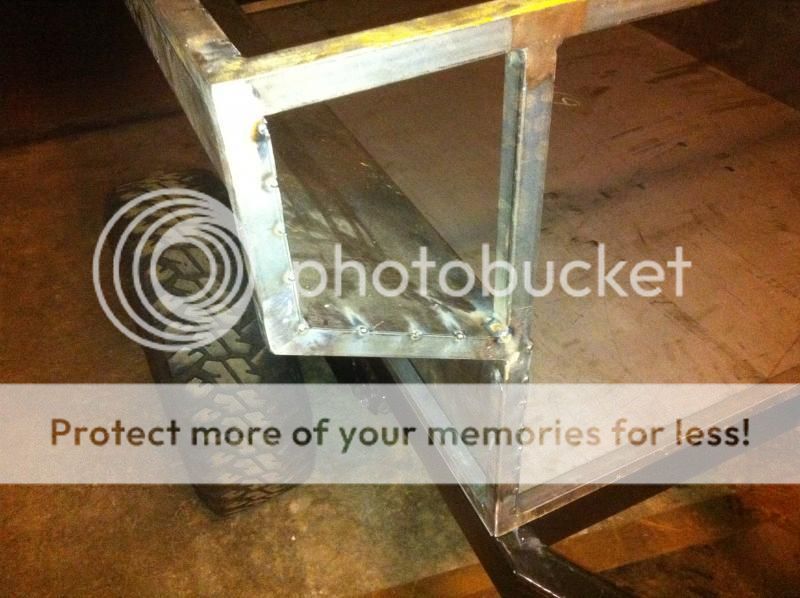

Frame:

The frame is primarily .125” wall 2”x4” rectangular tube with a built in receiver tube in the rear. The tongue telescopes with a .250 wall 3”x3” outer tube and .250 wall 2.5”x2.5” (receiver tube) extension. With the exception of the interior cross members (t welded) all joints were mitered and welded leaving no openings,

Frame:

The frame is primarily .125” wall 2”x4” rectangular tube with a built in receiver tube in the rear. The tongue telescopes with a .250 wall 3”x3” outer tube and .250 wall 2.5”x2.5” (receiver tube) extension. With the exception of the interior cross members (t welded) all joints were mitered and welded leaving no openings,