VerMonsterRV

Gotta Be Nuts

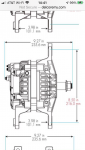

I think I have finally stumbled on a few things about alternators on our OM366LA engine. I suspect that this information is also usable for the OM352 engines and possibly other MB engines as I think the mounting points are similar (80mm foot seems to be the big thing). So here is goes, apparently Mercedes used the same mounting style on some of the newer engines which had higher amp alternators available. These higher amp alternators also have 2 internal fans for cooling, which I am hoping will allow them to last longer. The trick with the newer style though is you need to do a bit of extra wiring to get them to work. Oh, and this is for 24v trucks.

Here is a link to a 110amp Mahle available in the USA, there are other brands available in the 100amp range

And a link to a 150amp Bosch (and a couple of others) available in Europe (haven't found a USA supplier of a name brand one), MB part number A0001506550

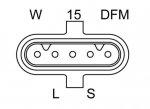

Some of the wiring you need to do is install a Bosch style plug, which is available here

This is an image of the Bosch plug pins

This is how to match the wires in the new plug to the existing wires, Stefan shared this information and it made things easy

W: Speed signal, for the LN2 the white/blue cable.

L: D+ , the blue cable on the LN2

15: Ignition plus (this cable must be installed retrospectively, when the ignition is on, current must be there)

S: Sense cable ( here a cable must be laid directly to the positive pole of the battery 1.5 mm2 is sufficient

DFM: This is a data line, where information about the current load status, temperature, etc. is output to other ECUs.

This image just help verify the wire color on the plug and what the function is.

Now one thing I learned replacing the last alternator. Most of the previous alternators I have worked with are case grounded. These alternators are also but I learned that the mounting foot has some rubber bushings so Mercedes installed a small ground cable that just went to a small case nut (probably fine on the lower amp alternator). I am guessing this might have led to our previous alternator early demise as I just reattached that small wire to the case, I just didn't see the rubber bushings and didn't understand why the ground cable was there. So with the new 110amp alternator I also installed a 2/0 ground cable which should be overkill.

As I am no electrician if anyone has anything to add feel free to jump on in.

Here is a link to a 110amp Mahle available in the USA, there are other brands available in the 100amp range

And a link to a 150amp Bosch (and a couple of others) available in Europe (haven't found a USA supplier of a name brand one), MB part number A0001506550

Some of the wiring you need to do is install a Bosch style plug, which is available here

Connector Alternator Repair Plug Harness 5-way 5pin bosch style Oval Plug 5 pins | eBay

Bosch Type Alternator ( Compare with your old Part). We Will Only Accept Our Products Which Are Unused, Unwrapped Or Never Installed.

www.ebay.com

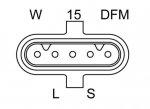

This is an image of the Bosch plug pins

This is how to match the wires in the new plug to the existing wires, Stefan shared this information and it made things easy

W: Speed signal, for the LN2 the white/blue cable.

L: D+ , the blue cable on the LN2

15: Ignition plus (this cable must be installed retrospectively, when the ignition is on, current must be there)

S: Sense cable ( here a cable must be laid directly to the positive pole of the battery 1.5 mm2 is sufficient

DFM: This is a data line, where information about the current load status, temperature, etc. is output to other ECUs.

This image just help verify the wire color on the plug and what the function is.

Now one thing I learned replacing the last alternator. Most of the previous alternators I have worked with are case grounded. These alternators are also but I learned that the mounting foot has some rubber bushings so Mercedes installed a small ground cable that just went to a small case nut (probably fine on the lower amp alternator). I am guessing this might have led to our previous alternator early demise as I just reattached that small wire to the case, I just didn't see the rubber bushings and didn't understand why the ground cable was there. So with the new 110amp alternator I also installed a 2/0 ground cable which should be overkill.

As I am no electrician if anyone has anything to add feel free to jump on in.