Inyo_man

Don't piss down my back and tell me it's raining.

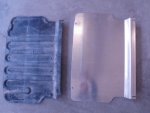

Since I wasn't able to find after market support in the way of Skid plates for my NM, I fabricated some.

I went back and forth about using alum. or steel, and decided on alum in the end.

For the sump/front diff. plate I started with the factory, plastic plate as a template.

I used 3/16'' (a bit over 4mm) in the T6 5052 Alum., since I needed to make the 60 degree Z bend in order to mount it the same as the factory plate. For the curves I used a jig saw with a coarse metal blade. Then filed and sanded the edges. I had a drill press to use, so the drilling of holes was very straight forward. For the slot mounts, I drilled the holes then made two parallel cuts up to the hole from the edge.

For the transmission pan plate I started with a cardboard template to get rough dimensions. I used 3/16'' T6 6061 for this, because there were no bends. For mounting it I used the factory tabs with welded on nuts located on the rear side of the cross member that receives the front diff. plate. These mount points had never been used. To mount the other side of the plate I drilled through the cross member where it pinches below the transmission pan. I drilled the holes in the cross member without dropping the member.

Using a right angle drill and a block of wood, I wedged the block of wood between the trans. pan and the cross member and drilled. If you have jack stands or ramps you could probably drill the holes with a standard cordless, but I have a right angle drill which made the job much easier. On this side I used through bolts with nuts.

Before the final install I tapped all of the factory tab welded nuts and replaced the bolts and washers with new ones.

This was a fun project.

I went back and forth about using alum. or steel, and decided on alum in the end.

For the sump/front diff. plate I started with the factory, plastic plate as a template.

I used 3/16'' (a bit over 4mm) in the T6 5052 Alum., since I needed to make the 60 degree Z bend in order to mount it the same as the factory plate. For the curves I used a jig saw with a coarse metal blade. Then filed and sanded the edges. I had a drill press to use, so the drilling of holes was very straight forward. For the slot mounts, I drilled the holes then made two parallel cuts up to the hole from the edge.

For the transmission pan plate I started with a cardboard template to get rough dimensions. I used 3/16'' T6 6061 for this, because there were no bends. For mounting it I used the factory tabs with welded on nuts located on the rear side of the cross member that receives the front diff. plate. These mount points had never been used. To mount the other side of the plate I drilled through the cross member where it pinches below the transmission pan. I drilled the holes in the cross member without dropping the member.

Using a right angle drill and a block of wood, I wedged the block of wood between the trans. pan and the cross member and drilled. If you have jack stands or ramps you could probably drill the holes with a standard cordless, but I have a right angle drill which made the job much easier. On this side I used through bolts with nuts.

Before the final install I tapped all of the factory tab welded nuts and replaced the bolts and washers with new ones.

This was a fun project.

Last edited: