I haven't watched the fuel gauge as I've filled the tanks, but I believe that the oem tank fills first. I think I read that in the manual, but now can't find the manual.

To fill all 40.6 gals (22.6 oem + 18 Aux, though the most I've filled is ~35gals, as I recall) you just put the nozzle in the tank and hope the pump has a high enough $ limit to allow a full fill up. The fueling is actually better than with just the stock tank, which in mine often spit some back toward the end. The better fueling may be the result of raising and repositioning the charcoal filter for better venting, don't know.

The Long Ranger website has some good photos of the tank, here's a link:

http://www.thelongranger.com.au/jklongrangefueltank.html

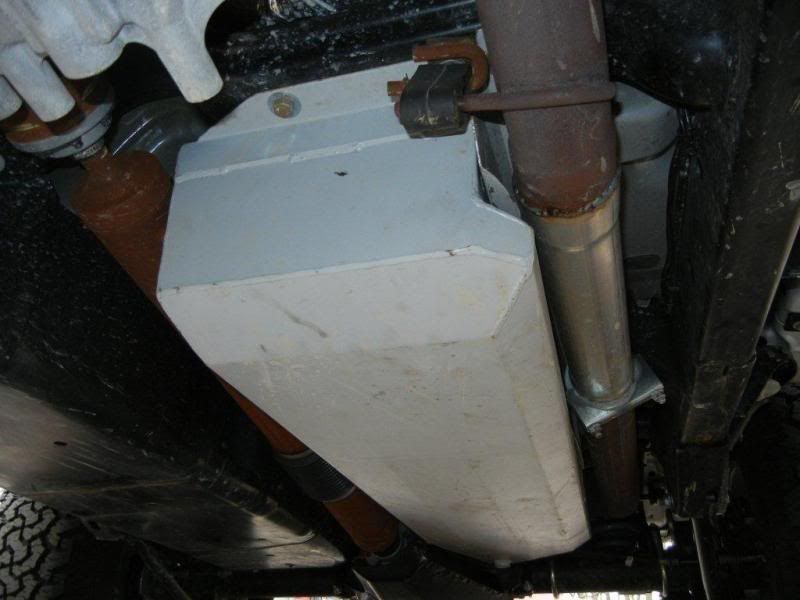

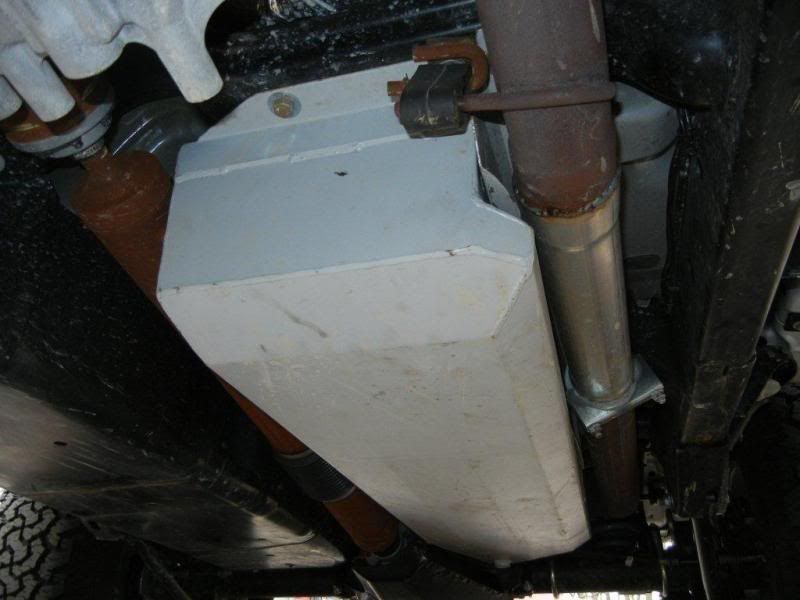

As the photos reveal, the hose is at the top of the aux tank and goes to the supplied pump. The aux tank remains full until you pump some or all of its contents to the oem tank. There is a supplied led gauge for the aux tank, and of course you have your oem gauge. You can transfer as much fuel as the oem tank needs when you wish by flicking the pump switch. The pump isn't fast and it takes maybe 40 minutes to transfer all 18 gals, or as much as will transfer - there must be some fuel you can't get to, as with any tank. The LR website gives a 1.7 litres/minute transfer rate.

I didn't do the instal, but I'm betting that the hose from the aux pump runs into the filler hose near the oem tank and the vent hose taps into the oem vent hose.

I suppose you could use a low mounted hose between the tanks. But to ensure that the oem pick up has fuel it can reach in an off camber situation, left/driver's side down, I'd suggest a check valve in the hose.

When we were figuring out how best to fab the skid for the aux tank, we considered going across the run between the tanks at the forward end of the rear DS. We didn't because there were adequate mounting points for the aux skid up front and we didn't need to, but at the front of the tanks you could run a skid between them without DS interference at full droop. That would protect the hose.

BTW, I'm almost certain it is a violation of federal regulations, and probably a bunch of state regulations too, to have a gravity feed, maybe a bottom feed of any sort, on an over the road fuel tank. If you search for diesel aux tanks, which is a target rich field to search as opposed to gas aux tanks, you will note that every maker of gravity feed aux tanks notes that a gravity feed system, allowing fuel to gravity feed from aux to oem tank, is for off road use only and/or has some other restriction. Also, diesel is diesel and gas ain't diesel. I think even refueing tanks that see over the road use need to be top pick up.

Also, if you have a tank made, it will need a roll over safe vent fitting both to meet regs and for basic safety. The roll over vent fittings work sort of like a check valve in reverse. They're readily available and not too expensive. Here's a link to a few.

http://www.jegs.com/p/JAZ/JAZ-Roll-Over-Vent-Valves/751554/10002/-1

I like this one too - top left:

http://www.jegs.com/webapp/wcs/stor...toreId=10001&Jnar=0&catalogId=10002&N=0&Nty=0

JPK