HSKR4X4

Adventurer

Power Stop Jeep JK Rear Brake Kit Write-Up & Install Guide

Power Stop Z36 Truck & Tow Brake Kit

2014 Part Numbers & Pricing

Front: K3097-36 ($179.00)

Rear: K3090-36 ($176.00)

Front & Rear: K2798-36 ($356.00)

FRONT WRITE-UP & INSTALL GUIDE LINK

http://www.expeditionportal.com/for...op-JK-Front-Brakes-Write-Up-amp-Install-Guide (CLINK ON LINK)

October 2015 10 Year Anniversary $30 Rebate Offer

• Celebrate Power Stop?s 10-Yr Anniversary with a huge Sale! | Power Stop (CLICK ON LINK)

Company Information

Power Stop Extreme Performance brake rotors and pads were first introduced in California in 1995 as a problem solver for the toughest brake challenges. Power Stop is committed to providing the safest and most effective braking solutions for its customer’s at an affordable price.

Power Stop set the standard when it introduced its first performance brake kit, the 1-Click Brake kit in 2011. Power Stop offers a complete line of application specific brake kits that includes as applicable: performance brake rotors, disc brake pads, brake hardware, brake sensors and calipers.

The “1-Click Brake Kit,” has revolutionized the way consumers purchase their brake parts and take the stress and guesswork out of selecting the right pad and rotor combination while delivering maximum performance and reliability. Don’t just Stop – Power Stop!

Brake Kit Information & Specs

Power Stop 1-Click Extreme Truck & Tow Brake Kits offer superior stopping power that is demanded by those that Tow/Haul, as well as the off-road enthusiast. Any time you add weight to a vehicle by hauling a load, towing a trailer, or simply adding a larger wheel/tire combination, you change the operating conditions of your stock brake package. Those operating conditions may exceed the ability of the stock braking components. The Power Stop 1-Click Extreme Truck & Tow Brake Kits are specifically matched components designed to produce the brake torque that is needed due to the increase in wheel diameter or load. The Drilled & Slotted rotors will reduce the heat and the Z36 Extreme Truck & Tow brake pads will provide the extra stopping power to bring your hauler to a halt quickly.

Warranty Information

60 Day Hassle-Free Warranty on top of a 3 year/36k mile warranty on all Power Stop 1- Click Brake Kits

IMPORTANT BREAK IN PRODECURE

• 5 moderate to aggressive stops from 40 mph down to 10 mph in rapid succession without letting the brakes cool and do not come to a complete stop. If you're forced to stop, either shift into neutral or give room in front so you can allow the vehicle to roll slightly while waiting for the light. The rotors will be very hot and holding down the brake pedal will allow the pad to create an imprint on the rotor. This is where the judder can originate from.

• Then do 5 mod¬erate stops from 35 mph to 5 mph in rapid succession without letting the brakes cool. You should expect to smell some resin as the brakes get hot.

• After this is complete, drive around for as long as possible without excessively heating the brakes and without coming to a complete stop (Try for about 5 minutes at moderate speed). This is the cooling stage. It allows the heated resin in the brake pads to cool and cure.

• After the brakes have cooled to standard operating temperature, you may use the brakes normally.

• For the first 100 miles, avoid towing or hauling loads while the pad completes the resin cure.

What Comes In Power Stop Kit

Rotors

Pads

Premium Hardware

Pin Bushing Kit

High Temperature Lubricant

Front Brake Install Guide

Install Time

1-2 Hours

Tools Needed

Refreshment of your choice

Flat Head Screwdriver

C-Clamp

Jack

Jack Stands (2)

½ or 3/8 Ratchet

Ratchet Extension

19 or ¾ Socket

13mm Wrench or Socket

15mm Wrench

18mm Wrench or Socket

Plyers

Brake Clean

Rags

Locktite (Blue)

Blocks/Wheel Chalk

Step 1

Lift Rear Of Jeep Off Ground

• Make sure you are parked on somewhat level ground, and place one block in front of front tire, and other in back of opposite front tire.

• Take 19mm/ ¾ Socket and loosen all 10 front lug nuts. (Don’t remove.)

• Take jack and place under pumpkin of housing. Jack to proper height and place one jack stand on each side of housing end under axle tubes.

Step 2

Remove One Wheel

• Leave other wheel during installation of new brakes.

• Remove the 5 loosened lug nuts, and slide wheel off studs.

• Place wheel that was removed under frame of rear door area.

Step 3

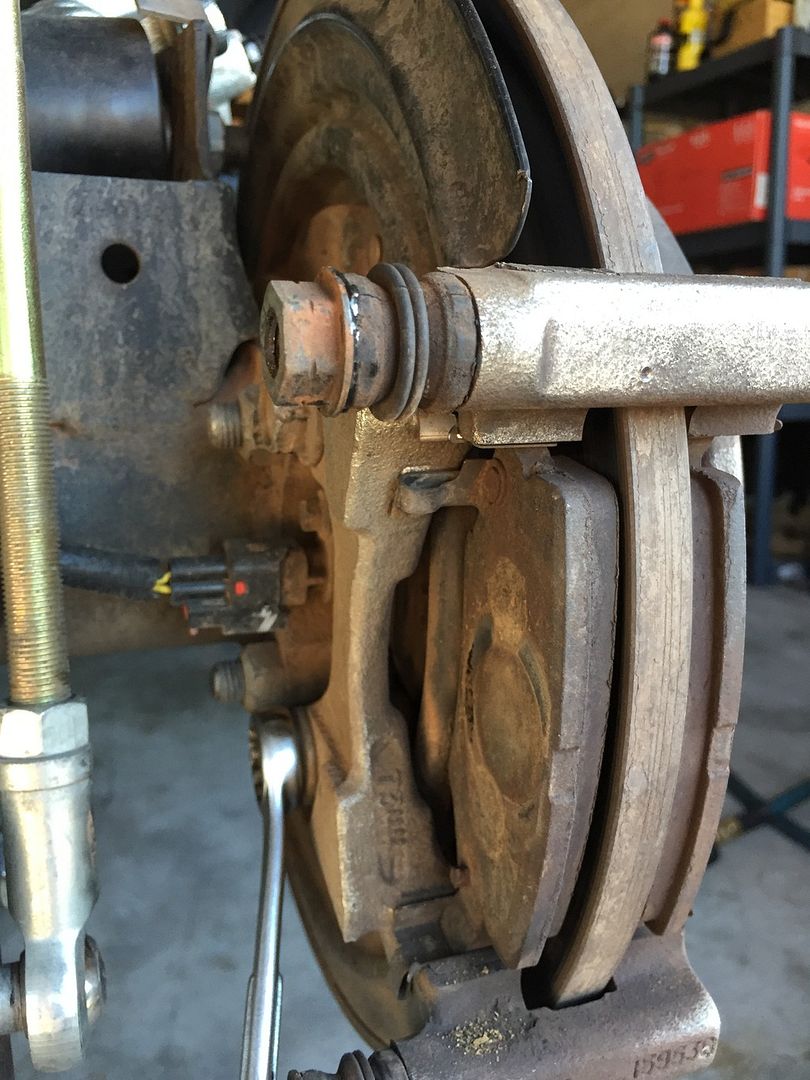

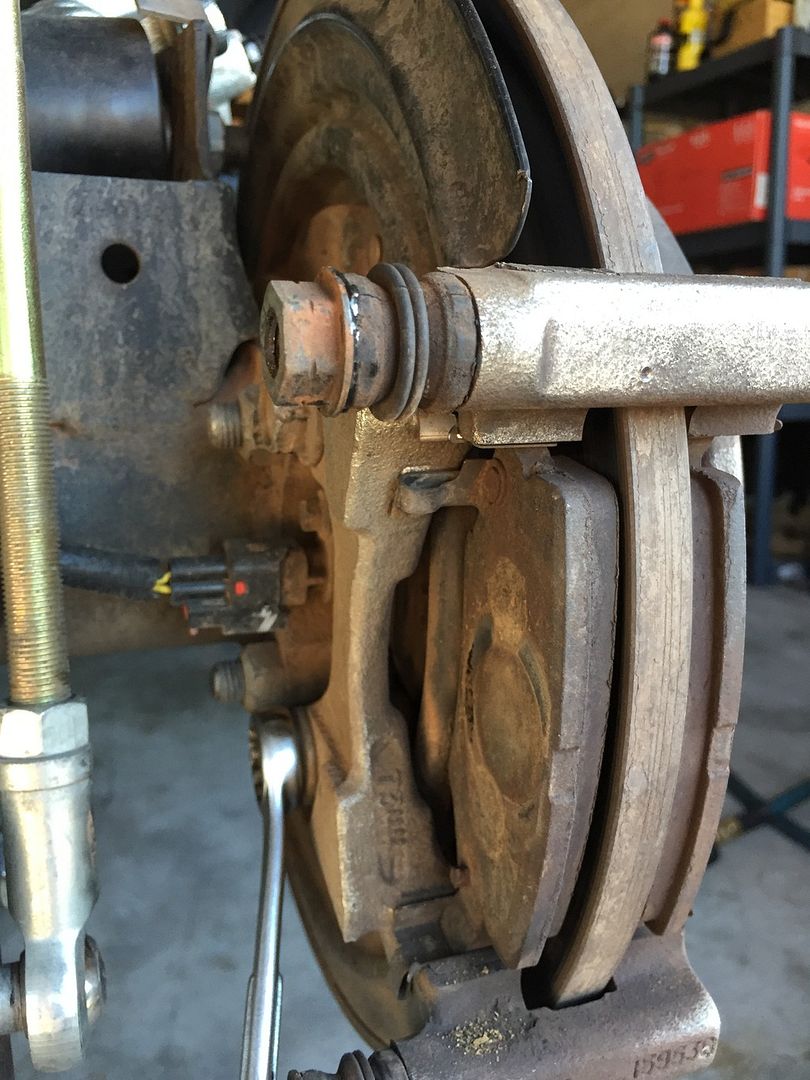

Remove Brake Caliper & Caliper Bracket

• Remove Rotor Retainers on studs if they are present. Use flat head or plyers to remove.

• Compress piston back with flat head screw driver with gentle force. By doing this, you will not have to bleed your brakes when finished.

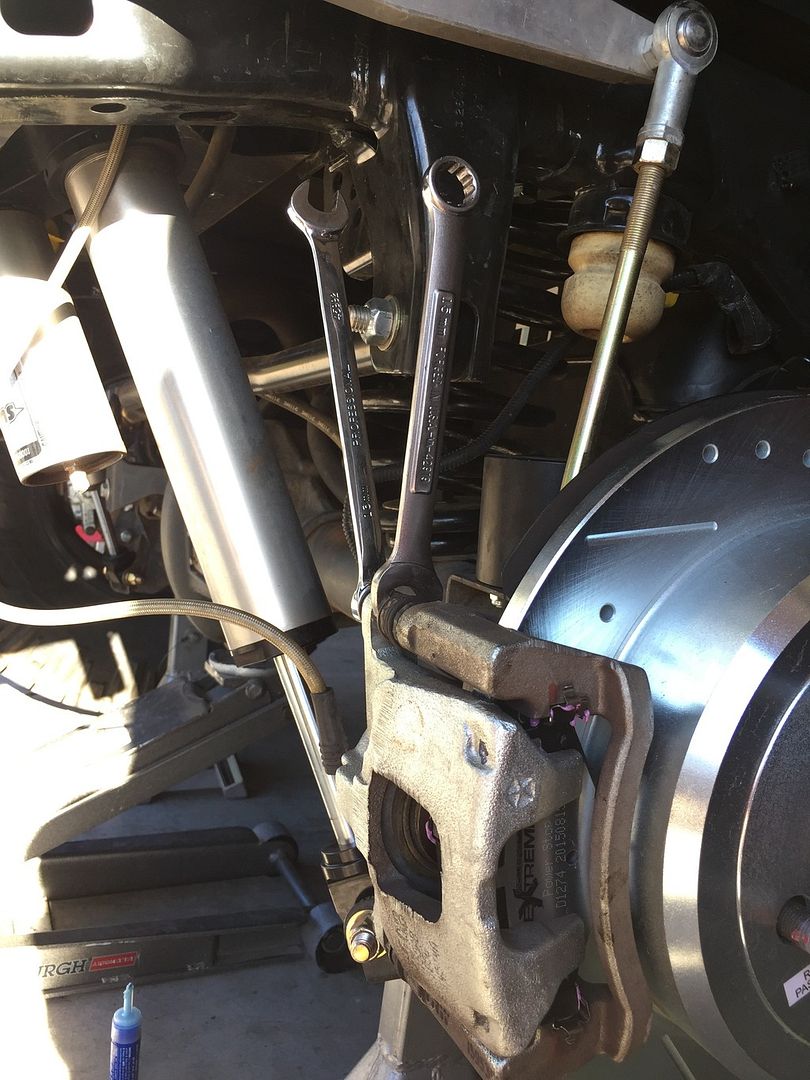

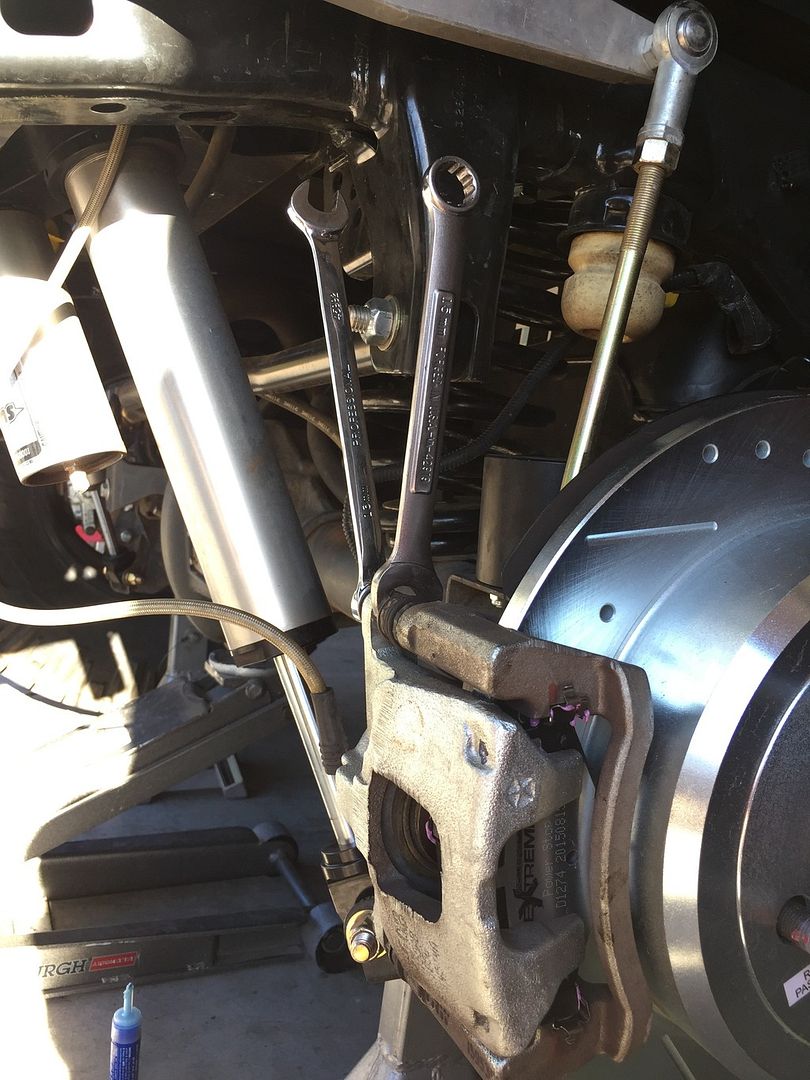

• Loosen caliper slide bolts with 13mm & 15mm wrenches. Hold 15mm in place while loosening with 13mm

• Move caliper up out of way and place bracket to the side. Make sure caliper it is sitting in safe spot or hanging with bungee and there is no stress on caliper brake lines.

• Remove caliper mount bolts with 18mm wrench/socket.

Step 4

Remove Rotor & Install New

• Slide rotor off now that caliper has been removed and out of way.

• Slide proper marked Power Brake rotor on, and screw on lug nut on to hold in place.

• Spray new rotor down with brake clean and wipe down.

Step 5

Prep Caliper Bracket

• Remove slide bolts, clean, install new boots clean regrease bolts with provided grease.

• Remove old brake hardware and install the new provided hardware as well. Flat lip of shims go up, and tongue clip goes towards outside.

Step 6

Install Caliper Bracket On To Rotor

• Put blue locktite on bolts.

• use 18 to tighten back down and torque to 120 ft.lb.

Step 7

Install Power Stop Pads & Piston Caliper

• Use provided grease, and lubricate the 3 edges of pads on each side that will slide into shims.

• Install pads on each side of rotor.

• Wipe down piston caliper, and use provided grease to grease piston and inner caliper where it touches pad. (This will promote brake from having any noise issues.)

• Slide caliper over bracket and tighten slide bolts with 13mm and 15mm. Once tight, torque bolts to 26 ft.lb.

• Remove lug nut that was holding rotor in place, spray brake clean on rotor and wipe clean one last time.

Step 8

Install Rear Wheel & Pump Brake

• Slide back on wheel and tighten down all lugs. (Don’t torque at this time)

• Once wheel is reinstalled, open Jeep door and pump brake with hand or foot. That will reseed brake to caliper and reset pads.

Step 9-16

**REPEAT STEPS FOR OPPOSITE SIDE**

Step 17

Final Installation

• Remove jack stands and Jack.

• Remove wheel blocks.

• Torque all 10 lugs in a cross pattern with 19/ ¾ socket to 95-120 ft.lb. (personal preference)

Power Stop Z36 Truck & Tow Brake Kit

2014 Part Numbers & Pricing

Front: K3097-36 ($179.00)

Rear: K3090-36 ($176.00)

Front & Rear: K2798-36 ($356.00)

FRONT WRITE-UP & INSTALL GUIDE LINK

http://www.expeditionportal.com/for...op-JK-Front-Brakes-Write-Up-amp-Install-Guide (CLINK ON LINK)

October 2015 10 Year Anniversary $30 Rebate Offer

• Celebrate Power Stop?s 10-Yr Anniversary with a huge Sale! | Power Stop (CLICK ON LINK)

Company Information

Power Stop Extreme Performance brake rotors and pads were first introduced in California in 1995 as a problem solver for the toughest brake challenges. Power Stop is committed to providing the safest and most effective braking solutions for its customer’s at an affordable price.

Power Stop set the standard when it introduced its first performance brake kit, the 1-Click Brake kit in 2011. Power Stop offers a complete line of application specific brake kits that includes as applicable: performance brake rotors, disc brake pads, brake hardware, brake sensors and calipers.

The “1-Click Brake Kit,” has revolutionized the way consumers purchase their brake parts and take the stress and guesswork out of selecting the right pad and rotor combination while delivering maximum performance and reliability. Don’t just Stop – Power Stop!

Brake Kit Information & Specs

Power Stop 1-Click Extreme Truck & Tow Brake Kits offer superior stopping power that is demanded by those that Tow/Haul, as well as the off-road enthusiast. Any time you add weight to a vehicle by hauling a load, towing a trailer, or simply adding a larger wheel/tire combination, you change the operating conditions of your stock brake package. Those operating conditions may exceed the ability of the stock braking components. The Power Stop 1-Click Extreme Truck & Tow Brake Kits are specifically matched components designed to produce the brake torque that is needed due to the increase in wheel diameter or load. The Drilled & Slotted rotors will reduce the heat and the Z36 Extreme Truck & Tow brake pads will provide the extra stopping power to bring your hauler to a halt quickly.

Warranty Information

60 Day Hassle-Free Warranty on top of a 3 year/36k mile warranty on all Power Stop 1- Click Brake Kits

IMPORTANT BREAK IN PRODECURE

• 5 moderate to aggressive stops from 40 mph down to 10 mph in rapid succession without letting the brakes cool and do not come to a complete stop. If you're forced to stop, either shift into neutral or give room in front so you can allow the vehicle to roll slightly while waiting for the light. The rotors will be very hot and holding down the brake pedal will allow the pad to create an imprint on the rotor. This is where the judder can originate from.

• Then do 5 mod¬erate stops from 35 mph to 5 mph in rapid succession without letting the brakes cool. You should expect to smell some resin as the brakes get hot.

• After this is complete, drive around for as long as possible without excessively heating the brakes and without coming to a complete stop (Try for about 5 minutes at moderate speed). This is the cooling stage. It allows the heated resin in the brake pads to cool and cure.

• After the brakes have cooled to standard operating temperature, you may use the brakes normally.

• For the first 100 miles, avoid towing or hauling loads while the pad completes the resin cure.

What Comes In Power Stop Kit

Rotors

Pads

Premium Hardware

Pin Bushing Kit

High Temperature Lubricant

Front Brake Install Guide

Install Time

1-2 Hours

Tools Needed

Refreshment of your choice

Flat Head Screwdriver

C-Clamp

Jack

Jack Stands (2)

½ or 3/8 Ratchet

Ratchet Extension

19 or ¾ Socket

13mm Wrench or Socket

15mm Wrench

18mm Wrench or Socket

Plyers

Brake Clean

Rags

Locktite (Blue)

Blocks/Wheel Chalk

Step 1

Lift Rear Of Jeep Off Ground

• Make sure you are parked on somewhat level ground, and place one block in front of front tire, and other in back of opposite front tire.

• Take 19mm/ ¾ Socket and loosen all 10 front lug nuts. (Don’t remove.)

• Take jack and place under pumpkin of housing. Jack to proper height and place one jack stand on each side of housing end under axle tubes.

Step 2

Remove One Wheel

• Leave other wheel during installation of new brakes.

• Remove the 5 loosened lug nuts, and slide wheel off studs.

• Place wheel that was removed under frame of rear door area.

Step 3

Remove Brake Caliper & Caliper Bracket

• Remove Rotor Retainers on studs if they are present. Use flat head or plyers to remove.

• Compress piston back with flat head screw driver with gentle force. By doing this, you will not have to bleed your brakes when finished.

• Loosen caliper slide bolts with 13mm & 15mm wrenches. Hold 15mm in place while loosening with 13mm

• Move caliper up out of way and place bracket to the side. Make sure caliper it is sitting in safe spot or hanging with bungee and there is no stress on caliper brake lines.

• Remove caliper mount bolts with 18mm wrench/socket.

Step 4

Remove Rotor & Install New

• Slide rotor off now that caliper has been removed and out of way.

• Slide proper marked Power Brake rotor on, and screw on lug nut on to hold in place.

• Spray new rotor down with brake clean and wipe down.

Step 5

Prep Caliper Bracket

• Remove slide bolts, clean, install new boots clean regrease bolts with provided grease.

• Remove old brake hardware and install the new provided hardware as well. Flat lip of shims go up, and tongue clip goes towards outside.

Step 6

Install Caliper Bracket On To Rotor

• Put blue locktite on bolts.

• use 18 to tighten back down and torque to 120 ft.lb.

Step 7

Install Power Stop Pads & Piston Caliper

• Use provided grease, and lubricate the 3 edges of pads on each side that will slide into shims.

• Install pads on each side of rotor.

• Wipe down piston caliper, and use provided grease to grease piston and inner caliper where it touches pad. (This will promote brake from having any noise issues.)

• Slide caliper over bracket and tighten slide bolts with 13mm and 15mm. Once tight, torque bolts to 26 ft.lb.

• Remove lug nut that was holding rotor in place, spray brake clean on rotor and wipe clean one last time.

Step 8

Install Rear Wheel & Pump Brake

• Slide back on wheel and tighten down all lugs. (Don’t torque at this time)

• Once wheel is reinstalled, open Jeep door and pump brake with hand or foot. That will reseed brake to caliper and reset pads.

Step 9-16

**REPEAT STEPS FOR OPPOSITE SIDE**

Step 17

Final Installation

• Remove jack stands and Jack.

• Remove wheel blocks.

• Torque all 10 lugs in a cross pattern with 19/ ¾ socket to 95-120 ft.lb. (personal preference)