2 bikes 2 brown dogs

Active member

I recently installed an Espar hydronic system with a Rixen control board and interface. I noticed that the room temperature readung would occasionally flash ERR. Eventually I figured out that the error would only happen when our water pump was running. The water pump is a 7.5 amp Shurflow 3 GPM.

My thought is the pump is creating voltage spikes that are significant enough to cause hiccups in the temp sensor.

This is a problem because if the hydronic system is trying to bring the room temp up the brief error flash basically makes the system think it has met the heating demand and the furnace immediately starts its shut down process.

I'll get into the specifics of the electrical system next but, at the end of the day, I'm looking for advice on sizing and installing a capacitor on the water pump circuit.

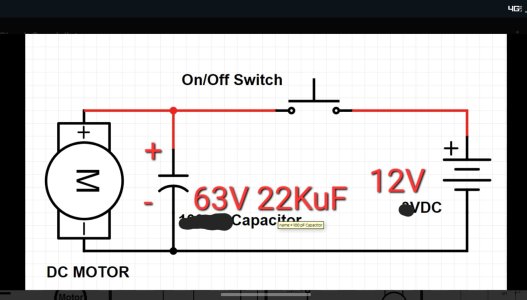

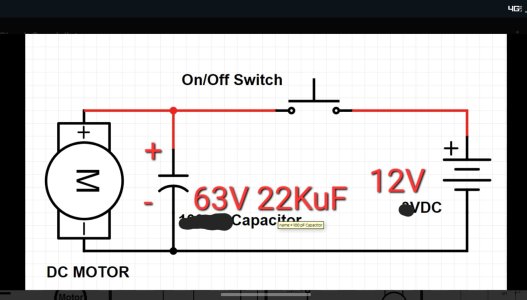

I ordered a 63 Volt 22,000 micro Farad aluminum electrolytic capacitor and attached a wiring diagram that shows my plan.

Right now the questions I know to ask are:

1. It seems like the capacitor's voltage rating is more of a maximum than a target with some tolerance. Is that accurate? I don't need a full understanding of the hows and whys but if there is an upper bound voltage that would be a safe limit, or less stupid, ide love to hear that.

2. Is the farad rating sufficient? If not at what point is oversized a problem.

3. I should have lead with this but is there a cleaner or better solution? What I've tried so far will be discussed later.

I'm very comfortable with the sizing and installation that went into the overall electric system. The big wires However, when it comes to the design of this "small" circuit saying "I'm in over my head" is an understatement.

However, when it comes to the design of this "small" circuit saying "I'm in over my head" is an understatement.

Now I'll dive into the background details.

My thought is the pump is creating voltage spikes that are significant enough to cause hiccups in the temp sensor.

This is a problem because if the hydronic system is trying to bring the room temp up the brief error flash basically makes the system think it has met the heating demand and the furnace immediately starts its shut down process.

I'll get into the specifics of the electrical system next but, at the end of the day, I'm looking for advice on sizing and installing a capacitor on the water pump circuit.

I ordered a 63 Volt 22,000 micro Farad aluminum electrolytic capacitor and attached a wiring diagram that shows my plan.

Right now the questions I know to ask are:

1. It seems like the capacitor's voltage rating is more of a maximum than a target with some tolerance. Is that accurate? I don't need a full understanding of the hows and whys but if there is an upper bound voltage that would be a safe limit, or less stupid, ide love to hear that.

2. Is the farad rating sufficient? If not at what point is oversized a problem.

3. I should have lead with this but is there a cleaner or better solution? What I've tried so far will be discussed later.

I'm very comfortable with the sizing and installation that went into the overall electric system. The big wires

Now I'll dive into the background details.