MotoDave

Explorer

I spent a couple of years building and wheeling my daily driver Toyota T100, and while fun at first I definitely found the wear and tear on the daily driver to be a drag. Not to mention the more I modified the truck, the more it sucked for on-road duties, as I’m sure most here know. I’ve always liked building things myself, so I started looking for a project that I could really get into and build as much as possible myself. I’m a mechanical engineer by trade, and find fabrication and welding to be a really enjoyable change from flying a workstation all day.

I bought this 1962 Scout 80 on Christmas day in 2010, from a family friend who was clearing out a collection of cars in preparation for a move. He has had it for 15+ years used as a utility truck to move cars around his property. My brother in law and the owner’s son both learned to drive in the truck.

My wife didn’t agree with me that this was all the Christmas present we needed.

I brought home in March 2011, and it sat for the better part of a year while I figured out exactly what I wanted to build, and collected parts.

The truck was complete when I brought it home, but had not run in ~10 years. I think the previous owner would have preferred that I rebuild it, but I wanted to build the truck with modern drivetrain, to be fairly trail capable but still comfortable enough to drive to and from the trails.

Hmm, the garage hasn’t looked this clean in a while ...

Specs (subject to change whenever my upgrade-itis kicks in)

This won’t be a fast build, but I’m hoping I’m to a point where I have the major parts collected and/or figure out, and will be able to update this often enough to keep it interesting.

I bought this 1962 Scout 80 on Christmas day in 2010, from a family friend who was clearing out a collection of cars in preparation for a move. He has had it for 15+ years used as a utility truck to move cars around his property. My brother in law and the owner’s son both learned to drive in the truck.

My wife didn’t agree with me that this was all the Christmas present we needed.

I brought home in March 2011, and it sat for the better part of a year while I figured out exactly what I wanted to build, and collected parts.

The truck was complete when I brought it home, but had not run in ~10 years. I think the previous owner would have preferred that I rebuild it, but I wanted to build the truck with modern drivetrain, to be fairly trail capable but still comfortable enough to drive to and from the trails.

Hmm, the garage hasn’t looked this clean in a while ...

Specs (subject to change whenever my upgrade-itis kicks in)

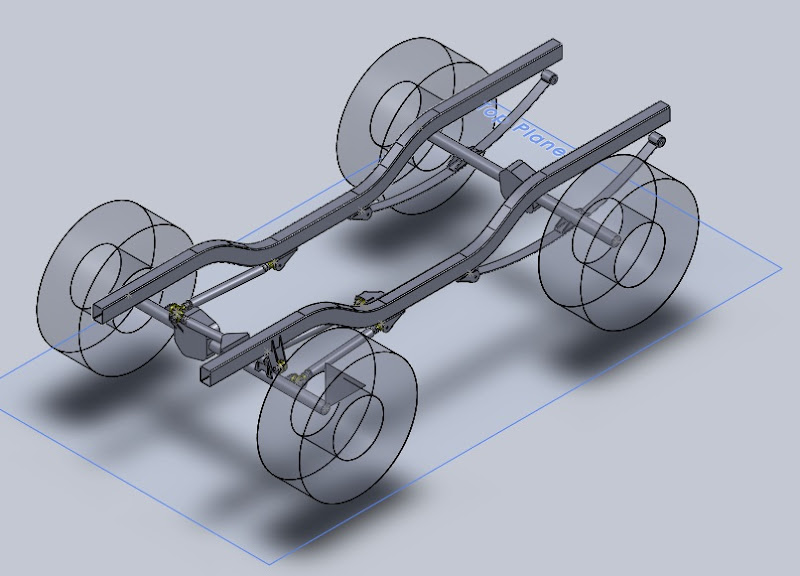

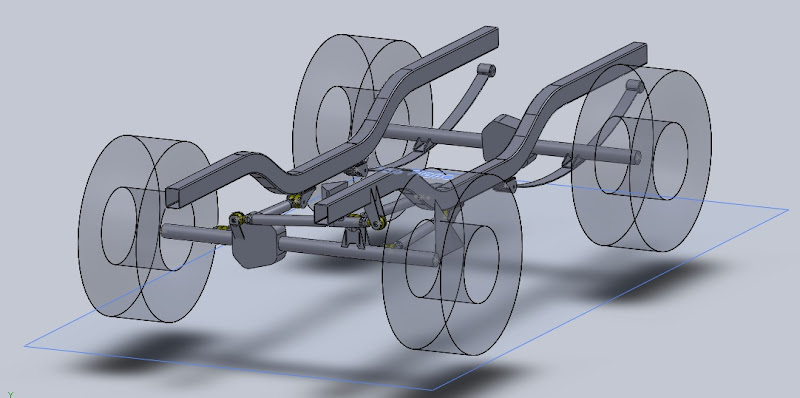

- Chevy 350 w/ TBI fuel injection

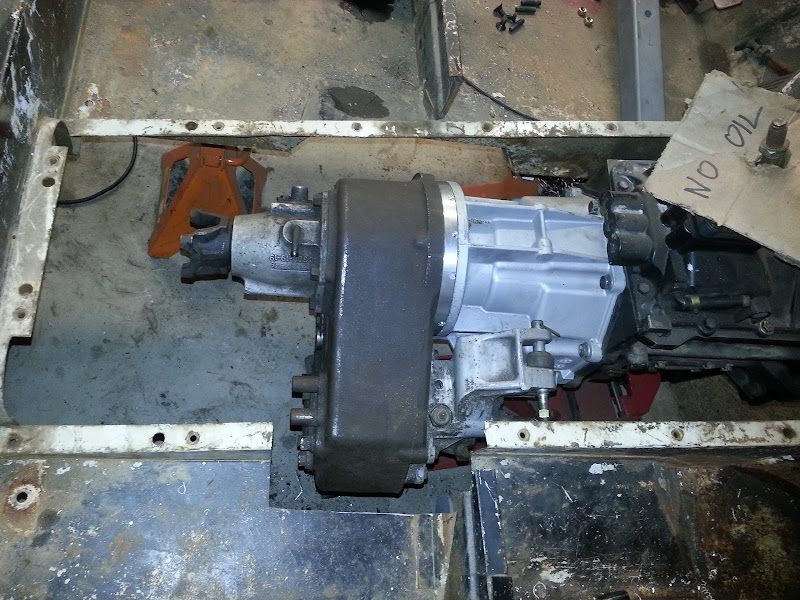

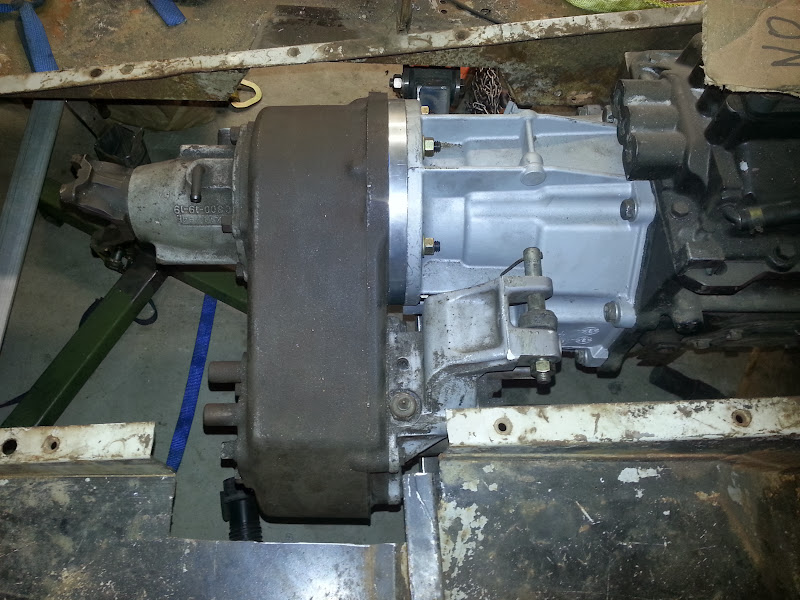

- Chevy NV4500, converted from 2wd to 4wd

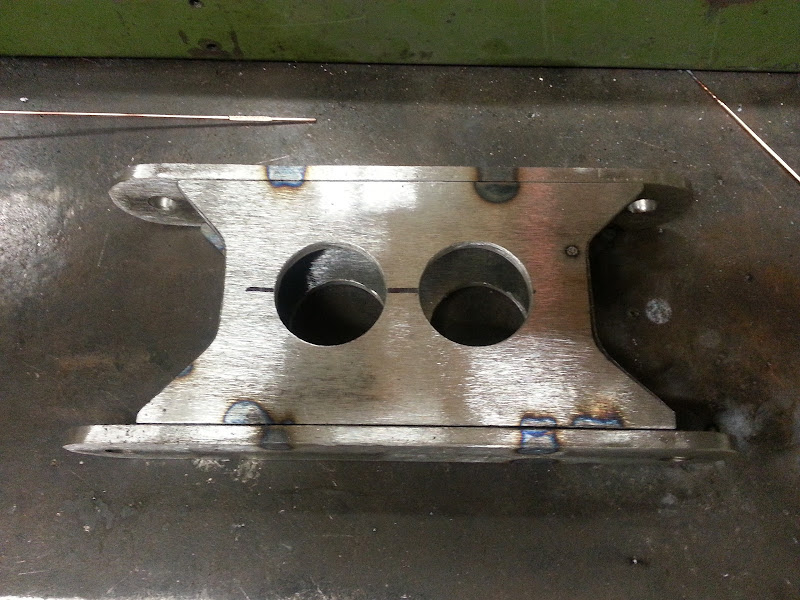

- Jeep Dana 300, w/ 32 spline input shaft (advance adapters)

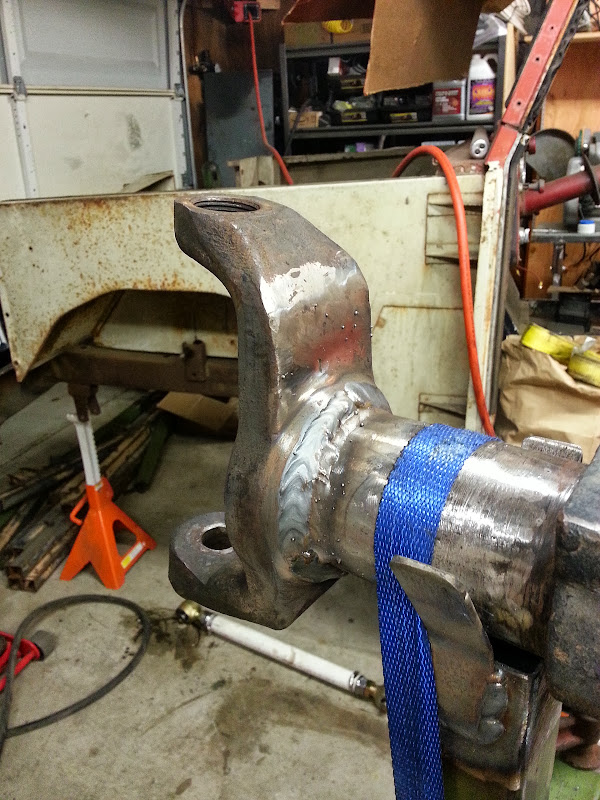

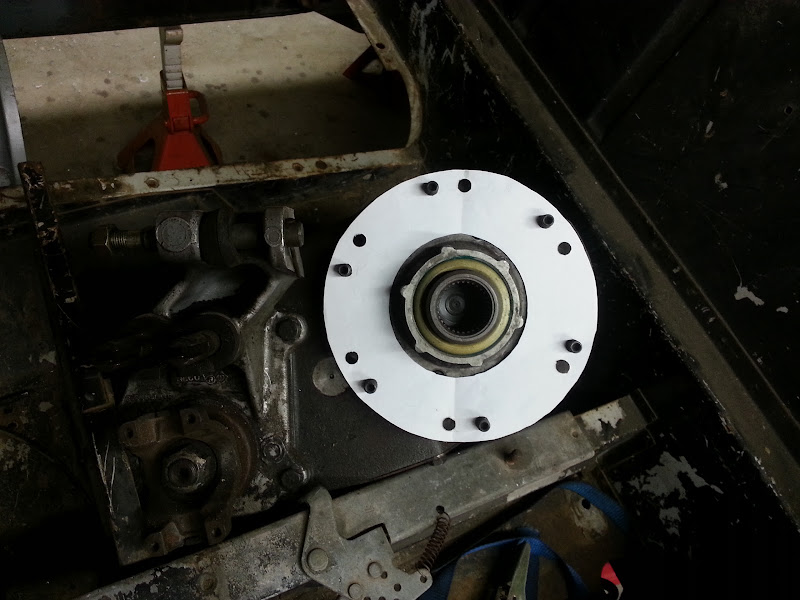

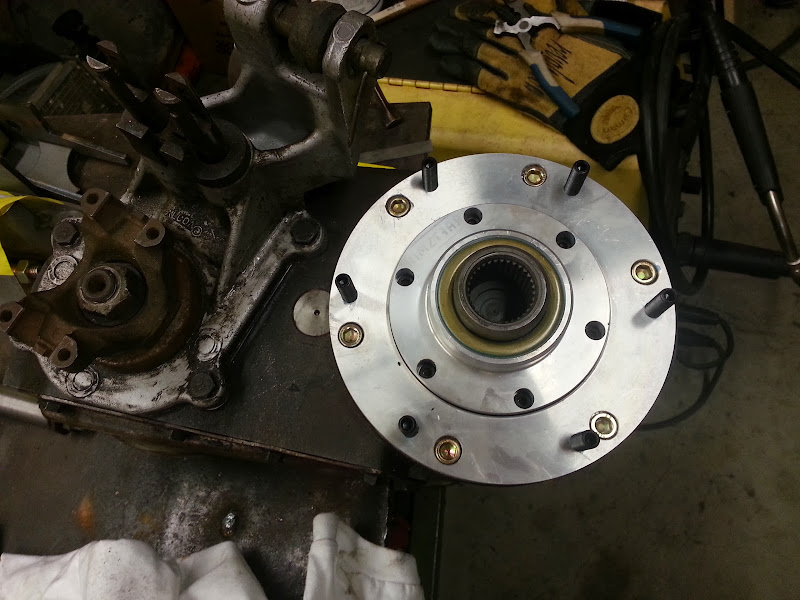

- Front Axle: Chevy Blazer Dana 44, Ford hubs and rotors. Narrowed to Scout II width to be able to use Scout II axle shafts.

- Rear Axle: Scout II Dana 44.

- Gearing: 4.56 all around. Detroit locker in rear, ARB air locker in front

- Tires: 35 x 12.5 x 15 BFG Mud Terrain

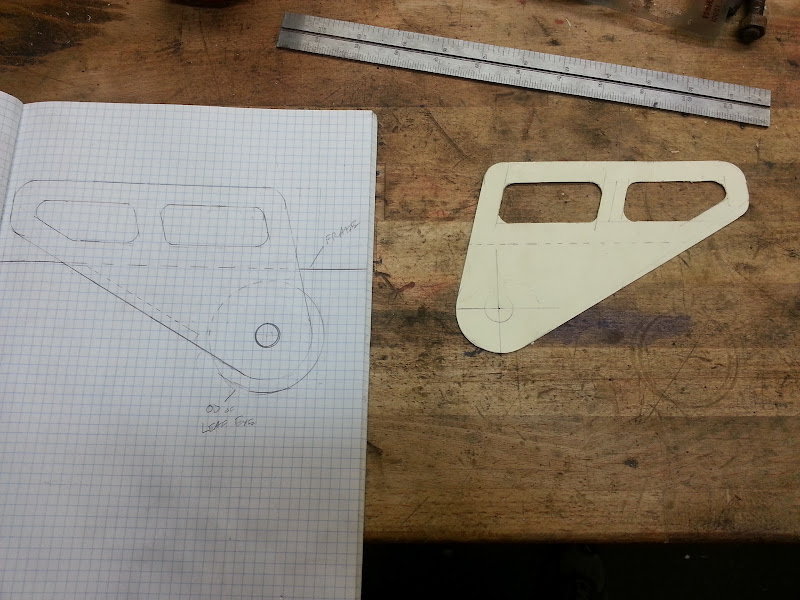

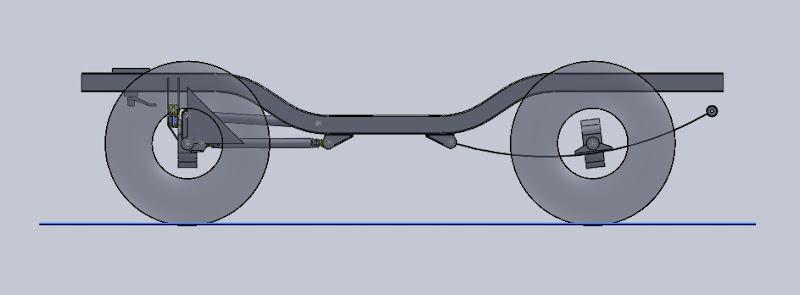

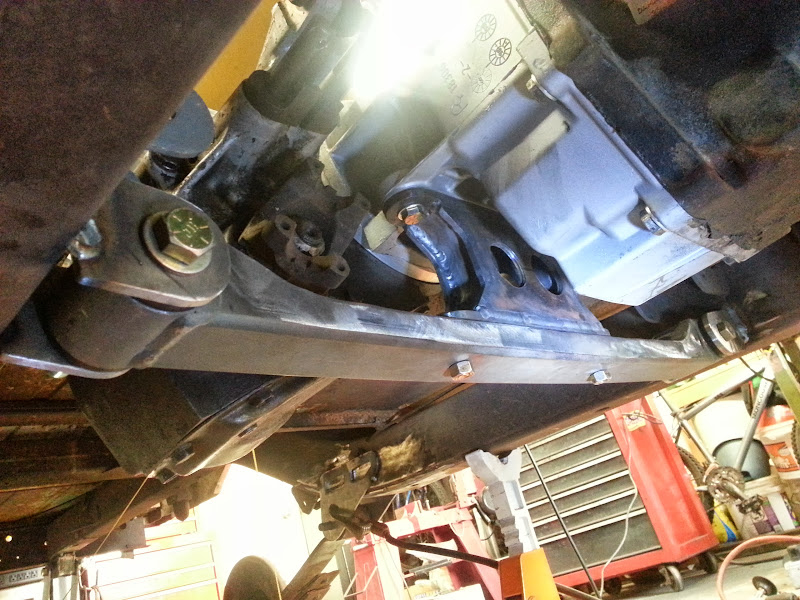

- Front Suspension : 3 link with coilovers

- Rear Suspension: 56” chevy leaf springs

This won’t be a fast build, but I’m hoping I’m to a point where I have the major parts collected and/or figure out, and will be able to update this often enough to keep it interesting.