I've looked through this forum and others for pro's/con's and general comparisons of the two skid plate set up's (aluminum and steel).

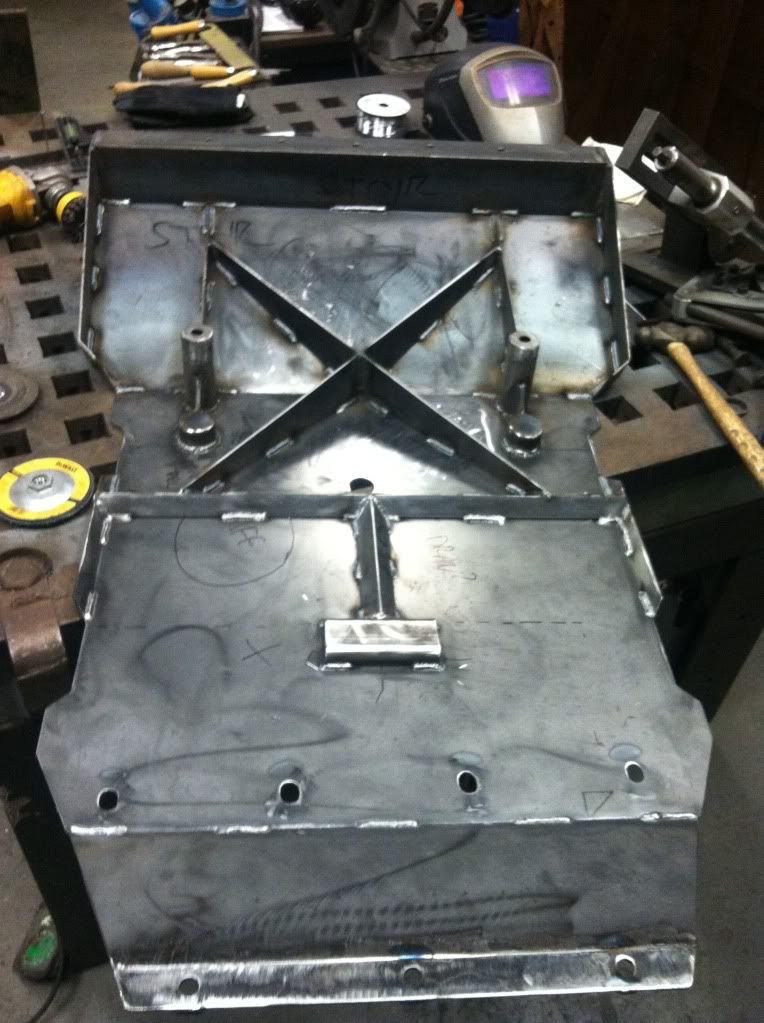

I have seen Toyota offer aluminum skid plates in their TRD line of products. Also, I've seen certain aftermarket companies, like RCI, offer aluminum skid plates. I know that in general aluminum is lighter (maybe less expensive too?) than steel, but steel, while heavier, offers greater durability and protection.

So my question is why when/where does it make sense to use aluminum over steel for skid plate protection?

Can aluminum withstand certain amounts of abuse on rocky and difficult terrain before they fail?

I get the sense that most hard-core rock crawlers go all out with full steel protection. Are there any overlanders who use aluminum skid plates while still tackling trails and moderately technical terrain?

Real-world experience/feedback would be greatly appreciated!

I have seen Toyota offer aluminum skid plates in their TRD line of products. Also, I've seen certain aftermarket companies, like RCI, offer aluminum skid plates. I know that in general aluminum is lighter (maybe less expensive too?) than steel, but steel, while heavier, offers greater durability and protection.

So my question is why when/where does it make sense to use aluminum over steel for skid plate protection?

Can aluminum withstand certain amounts of abuse on rocky and difficult terrain before they fail?

I get the sense that most hard-core rock crawlers go all out with full steel protection. Are there any overlanders who use aluminum skid plates while still tackling trails and moderately technical terrain?

Real-world experience/feedback would be greatly appreciated!