WanderOften

Member

I recently came across a post discussing the high costs of composite boxes, which presents a great opportunity for someone. I have a composite box that I imported directly from a high-quality Chinese manufacturer through a U.S. distributor. Unfortunately, the box suffered minor damage during the final leg of its transport. While insurance covered most of the replacement costs, I am looking to recoup the remaining expenses so I'm asking $8k. The cost of the windows, doors, and hatches alone would easily match the cost of this setup. I will be fully transparent about the work needed to restore this box to ideal condition, which I estimate will require 20-40 hours of labor. If there is no interest here on EP, I have other potential plans for the box

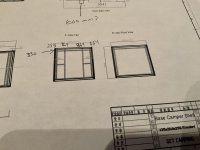

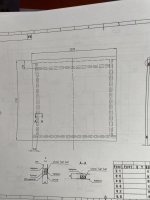

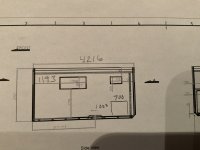

This box is 13’ 10” in exterior length 7’4” tall and 7’2” wide. The interior length is 13’5” by 6’8” wide by 6’8” tall. The box was designed to land on a mid-length Ford Transit Chassis cab(like an AeonRV) but certainly could be mounted on a variety of platforms. The roof floor and rear wall panels are constructed of 3” thick XPS foam with gloss fiberglass inside and the sidewalls and forward wallare 2” to easily accommodate windows and doors.

The windows and doors will look very familiar to those well-versed in high end parts and are all double-pane acrylic with day/night shades built in. Hatches are both insulated and locking and specially sized to accommodate a bike tray or larger items. The entry door is also of the highest quality, insulated, with dual locking mechanism, day night shades and built in storage/screen door. At the forward end of the box there’s a high-end Fantastic Fan installed. I had designed this box with a similar layout to beautiful AEONRV offering many options but the initial plan was for a rear-mount bed that would sit above the hatches. The floor contains fiberglass crossbeams with embedded steel mounting points. The rear wall also has some embedded steel to mount accessories.

Here’s what happened during transport and what needs to be done. The driver hauled the box on a flatbed and didn’t take precautions to spread out the load on the ratchet straps. This resulted in the aluminum angle that seals the corners breaking loose from the box. My manufacturer uses a sealant adhesive that isn’t overly aggressive, with the idea that if a tree branch or other object damages the aluminum angle, it would be easier to replace. In this case, it will make for a much easier repair. Realistically, I would replace the horizontal aluminum angle on both sides, top and bottom, as well as the one on the front wall. Some of the pieces were lost during transport, but I have enough here to easily replicate the replacement parts. The two vertical pieces on the front wall also need to be replaced, and ideally, new corner caps fabricated. I’m not sure I’d recycle the factory pieces unless they can be returned to their original shape. The 45-degree aluminum angle at the rear of the rig needs to be re-adhered to the body (a simple fix).

There is also some damage to the fiberglass that I would repair, as these are not difficult repairs and the work will be easily hidden under the aluminum angle. The passenger side upper corner of the fiberglass skin is damaged and needs a glass repair. While you might get away with leaving it as is, I would recommend fabricating a new corner for caution. There are also two small vertical cracks in the fiberglass at the base of the front wall that occurred when the box was removed from the container. These need a simple glass tape repair and can then be covered with fresh aluminum angle

Finally, there a few areas that need some easy buffing to clean up the finish. One area is at the front wall where the exposed wiring scuffed the wall surface. Same story on one of the sidewalls where the trucker neglected to secure one of his straps resulting in a marred finish.

This may sound like a lot of work, but I hope my photos will show that it’s really not too much of a chore and a way to get a super high-quality box at a very low cost. You’ll put in a little “sweat equity” but in the end you’ll have a fantastic habitat. I built a sled out of pressure treated 6x6’s that will go with the sale of the box. It’s designed so that the box can be moved easily onto a flatbed with a cable. That sled unit will go with the sale of the box to simplify transport. I’m sure there will be things I didn’t cover so feel free to ask any questions you have. I'm including photos of the box as it left the factory as well as some photos of the damage will need to do a second post as the platform only allows ten attachments I guess. Thanks for looking.

This box is 13’ 10” in exterior length 7’4” tall and 7’2” wide. The interior length is 13’5” by 6’8” wide by 6’8” tall. The box was designed to land on a mid-length Ford Transit Chassis cab(like an AeonRV) but certainly could be mounted on a variety of platforms. The roof floor and rear wall panels are constructed of 3” thick XPS foam with gloss fiberglass inside and the sidewalls and forward wallare 2” to easily accommodate windows and doors.

The windows and doors will look very familiar to those well-versed in high end parts and are all double-pane acrylic with day/night shades built in. Hatches are both insulated and locking and specially sized to accommodate a bike tray or larger items. The entry door is also of the highest quality, insulated, with dual locking mechanism, day night shades and built in storage/screen door. At the forward end of the box there’s a high-end Fantastic Fan installed. I had designed this box with a similar layout to beautiful AEONRV offering many options but the initial plan was for a rear-mount bed that would sit above the hatches. The floor contains fiberglass crossbeams with embedded steel mounting points. The rear wall also has some embedded steel to mount accessories.

Here’s what happened during transport and what needs to be done. The driver hauled the box on a flatbed and didn’t take precautions to spread out the load on the ratchet straps. This resulted in the aluminum angle that seals the corners breaking loose from the box. My manufacturer uses a sealant adhesive that isn’t overly aggressive, with the idea that if a tree branch or other object damages the aluminum angle, it would be easier to replace. In this case, it will make for a much easier repair. Realistically, I would replace the horizontal aluminum angle on both sides, top and bottom, as well as the one on the front wall. Some of the pieces were lost during transport, but I have enough here to easily replicate the replacement parts. The two vertical pieces on the front wall also need to be replaced, and ideally, new corner caps fabricated. I’m not sure I’d recycle the factory pieces unless they can be returned to their original shape. The 45-degree aluminum angle at the rear of the rig needs to be re-adhered to the body (a simple fix).

There is also some damage to the fiberglass that I would repair, as these are not difficult repairs and the work will be easily hidden under the aluminum angle. The passenger side upper corner of the fiberglass skin is damaged and needs a glass repair. While you might get away with leaving it as is, I would recommend fabricating a new corner for caution. There are also two small vertical cracks in the fiberglass at the base of the front wall that occurred when the box was removed from the container. These need a simple glass tape repair and can then be covered with fresh aluminum angle

Finally, there a few areas that need some easy buffing to clean up the finish. One area is at the front wall where the exposed wiring scuffed the wall surface. Same story on one of the sidewalls where the trucker neglected to secure one of his straps resulting in a marred finish.

This may sound like a lot of work, but I hope my photos will show that it’s really not too much of a chore and a way to get a super high-quality box at a very low cost. You’ll put in a little “sweat equity” but in the end you’ll have a fantastic habitat. I built a sled out of pressure treated 6x6’s that will go with the sale of the box. It’s designed so that the box can be moved easily onto a flatbed with a cable. That sled unit will go with the sale of the box to simplify transport. I’m sure there will be things I didn’t cover so feel free to ask any questions you have. I'm including photos of the box as it left the factory as well as some photos of the damage will need to do a second post as the platform only allows ten attachments I guess. Thanks for looking.