I'd like to focus on pickup trucks half ton - one ton including chassis cab with bolt on flatbeds.

Please share your experiences with your flatbed mounted composite panel campers without a pivoting subframe during off pavement use.

This subject path is well trodden but I wanted to revisit it to explore any new thinking that may have occurred over the last year. Most of the camper nerds here are well versed in this subject matter but I'll include some basic descriptions so anyone new to the subject can easily join in.

Types of camper construction

Camper units are successfully carried in standard pickup truck beds and it is generally accepted that the trucks torsional frame twist doesn't ruin the camper if the tiedowns have some compliance. Traditional tie down points are usually brackets mounted to the truck's bed, frame, and / or rear bumper.

Traditional camper construction systems (1950's - 1990's) comprised of wood stick frame, plywood sections and segmented aluminum skin panel structures are the most flexible of all the various types of construction methods and allow for the most deformation before structural failure. Granted the exterior seams likely loosened up and leaked over time but could be resealed.

The next generation of campers diverged in construction along two general paths both resulting in more rigid structures. Fiberglass clamshell construction and the other being plywood exterior with laminated FRP skins. Both of these systems are proven to work when tied down in a standard pickup bed or flatbed.

The newest generation of camper construction is a system utilizing composite panels comprised of a matrix of FRP skins bonded to a foam or polyethylene honeycomb core and results in a very rigid structure. This type of structure doesn't flex much and if forced to flex, there is a high likely hood of mechanical failure.

Camper shapes

Campers that slide into pickup truck beds have a common shape that allows them to pass between the truck bed's internal wheel wells. The shape in plan view is a T. They are wide aft of the wheel wells and narrow between the wheel wells up to the front of the bed.

A more recent truck camper shape in plan view is a rectangle and requires a "flatbed or subframe for mounting. Won't fit between a pickup truck bed wheel wells. These shapes are most commonly comprised of rigid composite panels.

Forces on campers at mounting points

When a vehicle is fastened to a camper it now becomes a system where one exerts force on the other. In order to stay out of the weeds and simplify things, this description will focus on static loading only forgoing dynamic loading complexities.

In a static flat ground condition, the forces between the vehicle and camper do not apply a torsional or twisting load on the camper.

When a vehicle is sitting on uneven ground where the wheels are on different elevations relative to each other, the vehicles frame deflects or bends causing a twist in the frame. When the vehicle frame twists, the camper either remains rigid separating from the frame or is forced to deflect and twist with the frame.

There are two areas of contact on a camper where forces are exerted on them. The tiedown mounting points usually at 4 external corners and the bottom of the camper where it contacts the vehicle.

When tiedowns at the 4 corners of the camper have built in springs or compliance they allow for a limited separation of the camper and vehicle when undergoing a torsional twisting load. I believe the importance of the separation is that the forces transferred to camper can be more isolated to the tie down mounting points which are hopefully located in higher strength areas.

I also speculate that and advantage to compliant tiedowns comes when the torsional loading is more dynamic and relative to time or how fast the force is applied to the camper. More of an energy transfer rate analysis.

How the forces are applied between the bottom of the camper and where it contacts the vehicle vary based on its bottom shape. Campers with a T shape or narrow bottom are more forgiving than a rectangle. This is due to the change in distance that occurs when something flat is twisted or the amount of deflection at a distance from center. When a frame twists, the deflection or change in dimension increases from the middle to outer edge. This is the main case for developing a pivoting subframe and not hard mounting a very rigid composite box to a vehicle's frame (warning: massive rabbit hole and significant added cost).

Discussion

Is there a takeaway from the traditional mounting of truck bed camper with T shaped bottom that could be applied and utilized when mounting a rectangular composite camper box on a basic non pivoting flatbed?

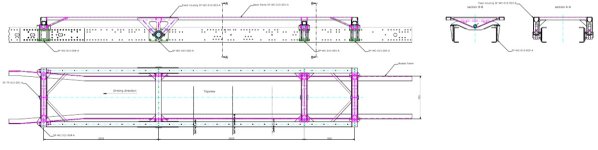

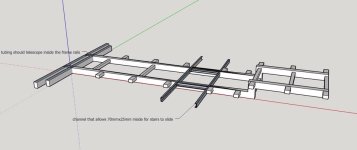

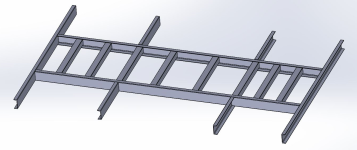

Can a rectangular composite box be supported by a narrow T shaped platform that doesn't extend to its outer corners?

Please share your experiences with your flatbed mounted composite panel campers without a pivoting subframe during off pavement use.

This subject path is well trodden but I wanted to revisit it to explore any new thinking that may have occurred over the last year. Most of the camper nerds here are well versed in this subject matter but I'll include some basic descriptions so anyone new to the subject can easily join in.

Types of camper construction

Camper units are successfully carried in standard pickup truck beds and it is generally accepted that the trucks torsional frame twist doesn't ruin the camper if the tiedowns have some compliance. Traditional tie down points are usually brackets mounted to the truck's bed, frame, and / or rear bumper.

Traditional camper construction systems (1950's - 1990's) comprised of wood stick frame, plywood sections and segmented aluminum skin panel structures are the most flexible of all the various types of construction methods and allow for the most deformation before structural failure. Granted the exterior seams likely loosened up and leaked over time but could be resealed.

The next generation of campers diverged in construction along two general paths both resulting in more rigid structures. Fiberglass clamshell construction and the other being plywood exterior with laminated FRP skins. Both of these systems are proven to work when tied down in a standard pickup bed or flatbed.

The newest generation of camper construction is a system utilizing composite panels comprised of a matrix of FRP skins bonded to a foam or polyethylene honeycomb core and results in a very rigid structure. This type of structure doesn't flex much and if forced to flex, there is a high likely hood of mechanical failure.

Camper shapes

Campers that slide into pickup truck beds have a common shape that allows them to pass between the truck bed's internal wheel wells. The shape in plan view is a T. They are wide aft of the wheel wells and narrow between the wheel wells up to the front of the bed.

A more recent truck camper shape in plan view is a rectangle and requires a "flatbed or subframe for mounting. Won't fit between a pickup truck bed wheel wells. These shapes are most commonly comprised of rigid composite panels.

Forces on campers at mounting points

When a vehicle is fastened to a camper it now becomes a system where one exerts force on the other. In order to stay out of the weeds and simplify things, this description will focus on static loading only forgoing dynamic loading complexities.

In a static flat ground condition, the forces between the vehicle and camper do not apply a torsional or twisting load on the camper.

When a vehicle is sitting on uneven ground where the wheels are on different elevations relative to each other, the vehicles frame deflects or bends causing a twist in the frame. When the vehicle frame twists, the camper either remains rigid separating from the frame or is forced to deflect and twist with the frame.

There are two areas of contact on a camper where forces are exerted on them. The tiedown mounting points usually at 4 external corners and the bottom of the camper where it contacts the vehicle.

When tiedowns at the 4 corners of the camper have built in springs or compliance they allow for a limited separation of the camper and vehicle when undergoing a torsional twisting load. I believe the importance of the separation is that the forces transferred to camper can be more isolated to the tie down mounting points which are hopefully located in higher strength areas.

I also speculate that and advantage to compliant tiedowns comes when the torsional loading is more dynamic and relative to time or how fast the force is applied to the camper. More of an energy transfer rate analysis.

How the forces are applied between the bottom of the camper and where it contacts the vehicle vary based on its bottom shape. Campers with a T shape or narrow bottom are more forgiving than a rectangle. This is due to the change in distance that occurs when something flat is twisted or the amount of deflection at a distance from center. When a frame twists, the deflection or change in dimension increases from the middle to outer edge. This is the main case for developing a pivoting subframe and not hard mounting a very rigid composite box to a vehicle's frame (warning: massive rabbit hole and significant added cost).

Discussion

Is there a takeaway from the traditional mounting of truck bed camper with T shaped bottom that could be applied and utilized when mounting a rectangular composite camper box on a basic non pivoting flatbed?

Can a rectangular composite box be supported by a narrow T shaped platform that doesn't extend to its outer corners?

Last edited: