Buliwyf

Viking with a Hammer

New guy. So bear:elkgrin: with me, I didn't see a new guy introduction forum here. I have spent alot of time with Ford Superduty work trucks, and just recently sold my Truck. My Jeep Yj isn't streetable.

So I'm looking to start a new build along the same practical camping, mild offroad, and rural highway travel alot of others here seem to embrace. I'm envious of alot of the builds here. It's nice to see tuned up trucks for a real practical purpose. Not just huge lifted show queens. (I'm ok with those, just not my style)

Hopefully I can add my experience to truck tech threads. I was a Master tech for a very short period of time before I became a generator tech many years ago.

Anyways I'm buying a Superduty this fall when prices drop as the next year models come out and fuel prices are usually high driving demand down. Not sure if I'm buying new or buying used at this point. Depends on if I can get a deal on a new truck. I can buy a fairly decent used truck for the cost of depreciation on a new one.

Lucky for me I don't need a daily driver. I have a work Van I take home that's provided by my employer. So I can make some consessions towards something a bit more aggressive than most people. Fuel economy deosnt really matter for example. I only fill my cars tank twice a month or less. Often my company vehicle can e used on my way home for most of my chores. And I allready own a small car for "boring adventureless" travel.

So onto the build plan, any advice is appreciated:

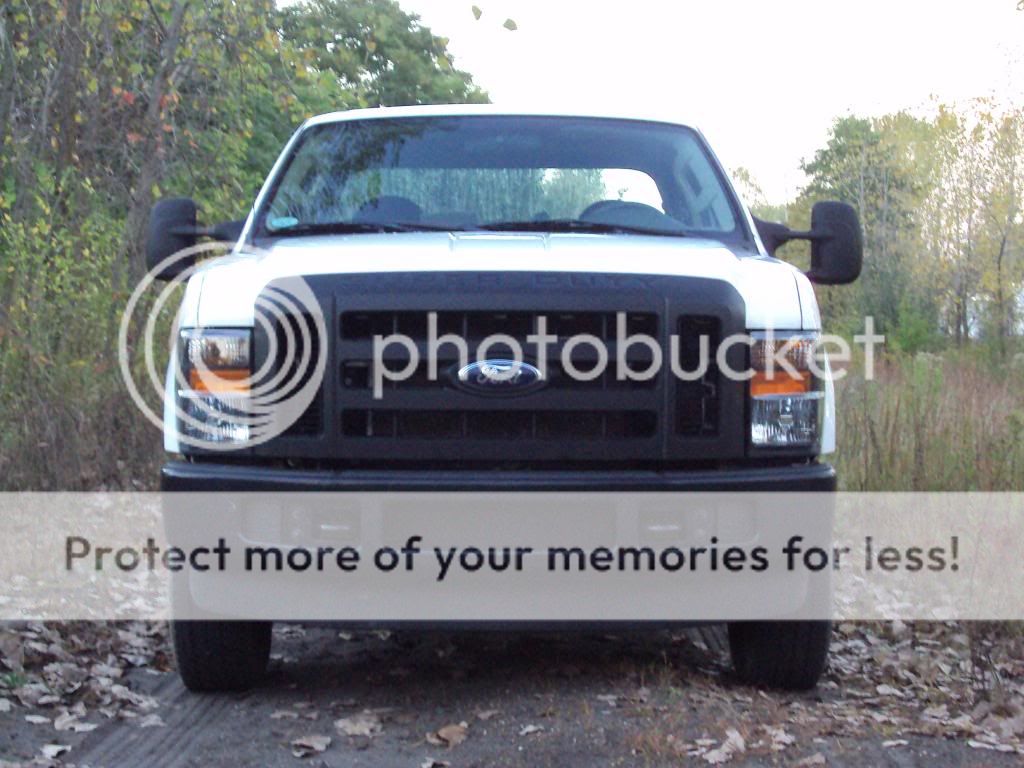

The truck -I'm starting with a Ford Superduty F250/F350. Also staying with XL model work trucks. Manual locks and windows. Nothing to fail, nothing to spaz out and lock me outside my truck on a cold day. Buying a used truck with cash is a nice idea, but given my lifestyle, a brand new truck could last me 20+ years easy.

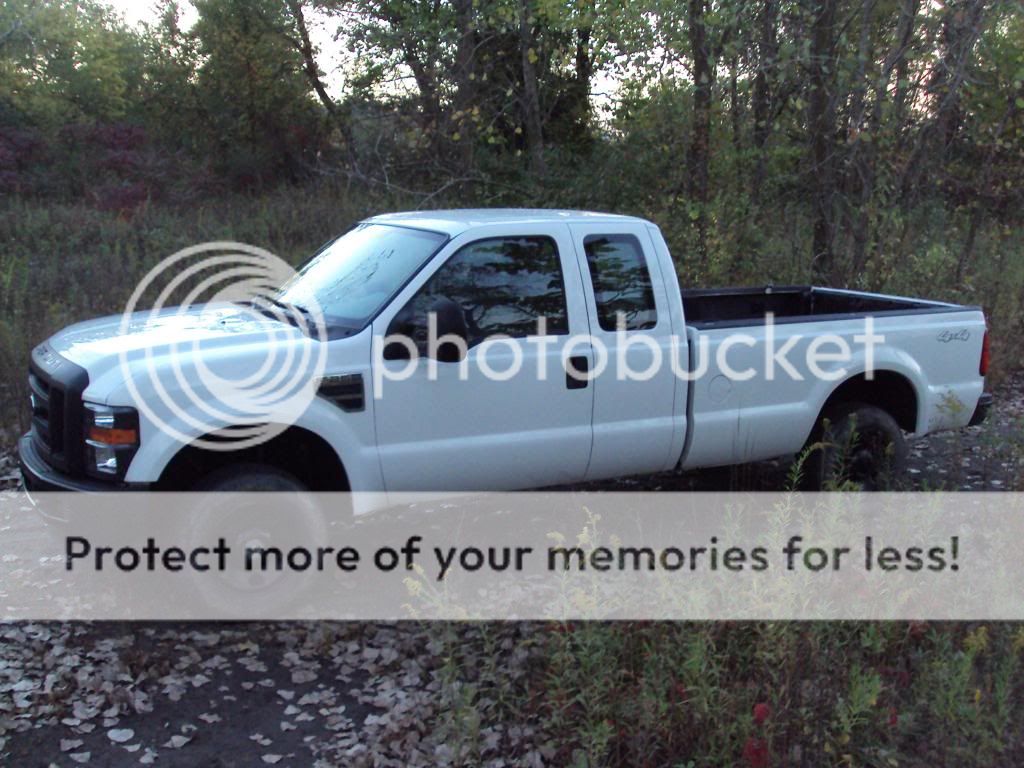

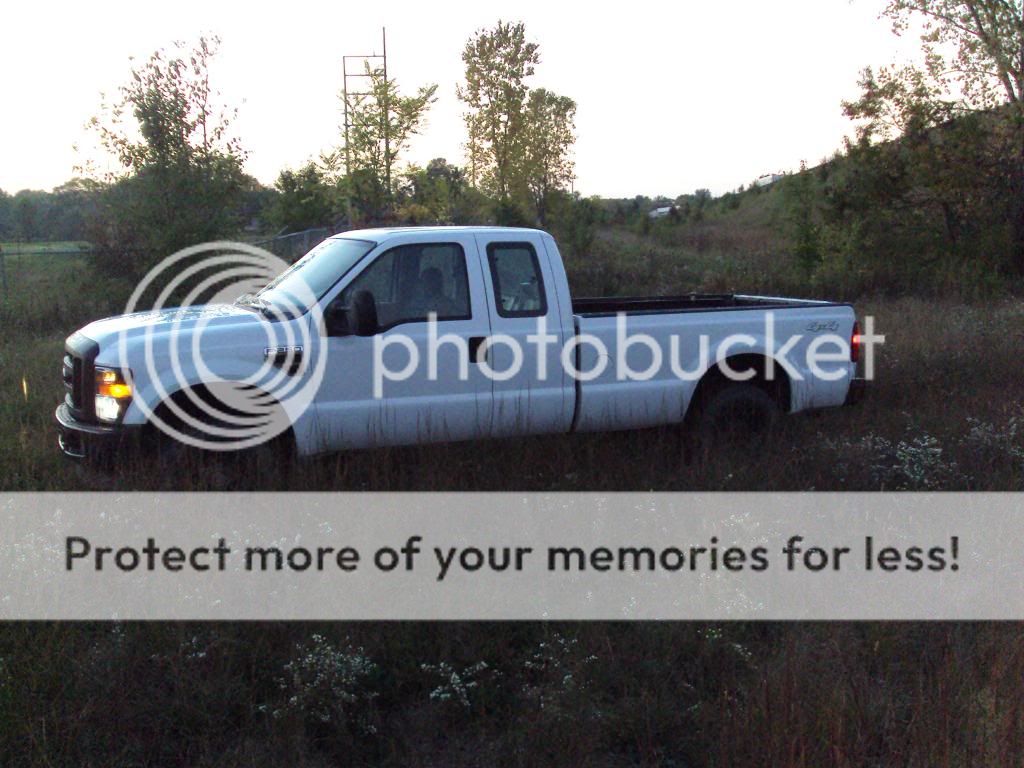

This kind of truck is what I'll be checking out over the next three months:

New or slightly used:$27k-35k

:elkgrin:

:elkgrin:

Or the same type of truck used, year 2000 and up with less than 100,000 miles. These are usually around $10k in my area and often in very good shape.

Since I'm only looking at white base model work 4x4's, many of these used trucks come with torn steering wheels or seats. Who hasn't jumped into their work truck with a sharp screwdriver in thier pocket? That makes them impossible to sell to "normal people". I usually add seat covers and can replace a steering wheel easy enough. I'll most likely replace the brakes with thick Napa rotors and and if I need to, eventually rebuild the transmission. But plenty of city/county trucks see light use compared to a plow truck or daily driver. Just have to know what to look for. The tansmission appears to be the weak link of these trucks. But trans shops are getting good at repairing them.

My needs require:

-Dana 60 front axle. No 1998-2001's with Dana 50's please.

-Sterling/Visteon 10.5" rear end. Which, I imagine, becomes a 10.25 when I regear it.

-Manual hubs, manual transfer case. Old school tough.

-XL interior. Less to break, rubber floors like mud.

-No engine mods, no lifted trucks, no project truck like this. (Usually a bad sign when buying used)

If I buy new, I want the F250. I prefer it's vacuum boost brakes over the F350's hydro boost. The F350 requires less effort to stop with a trailer, but you can feel it tug on the powersteering pump when offroad or manuvering trailers in parking spots. The F250 is cheaper to insure and license as well and I only tow up to 10,000 pounds, never more.

Even though the F250's come with the smaller "5th wheel trailer height" blocks in the rear, I'll be swapping those out soon enough anyways.

Suspension:

BDS 4" would be nice, but overkill.

A 2" leveling kit and 305 sized tires (33") would suit my needs as well. But when you add an adjustabe track bar to get the front end perfect, the overall cost is similar to a complete 4" system. I may not add the 4 link, it's about a $500 option. But it's probally worthwhile.

[

Drivetrain:

Detroit Locker in the rear. I've never had problems with the fullcase Detroit in heavy fullsize trucks. Actually more predictable than the Ford LSD ( I shimmed it tight and used no friction modifier) I used in a previous truck. I like how these ratchet off road in turns. I don't like constantly switching off an ARB. And the Detroit works great, for me, in alot of places that it isn't wise to completely lock an axle. I love being able to gently craw through off road sections. I am not the type to use momentum often. So if that means investing in lockers, and/or stopping to put mud chains on, so be it.

Open diff up front, or if the budget allows an Ox selectable locker up front. I'd run a long Ox cable to the frame, not to the cab. Then I'd use the electric solenoid kit on the frame to actuate the ox locker. Easier, cleaner, cable run that way. A simple cheaper Detroit up front is tempting. But only if i rarely need 4wd on the street in snow. With a Detroit in the rear, my experience is that it's critical to be in 4wd when there is not pavement showing. So open or selectable is the way I need to go I think up front.

No need for fancy axle shafts. Allready running 1ton beef. I may need to a CV stle driveshaft to get rid of vibration with a short lifted truck, but that's unlikely. 4" is barely taller than stock overall.

Engine:

Stock. Fords have plenty of grunt as long as they are geared proper. 300HP is plenty.

I'm after the 6.2L or 5.4L gas engines.

I'm a hardcore diesel guy. But I have enough experience with those to know they won't suit my needs for this build. Extra weight and extra up front cost. I don't tow that often. And I usually can acheive 8-9 mpg, with a gas engine, pulling 9,000 pound generator trailers.

Recovery gear:

The Jeep had a winch. I loved it. But it's not needed with this build. I see a ton of salt/snow so a winch would be repaired more often than used. Not to mention, there is nothing within 100' of a Superduty anytime it actualy deos get stuck. At least never anything that can handle 10,000 pounds of pull.

So I better plan on not being winchable. Shovel, highlift, and wheel grabber for the high lift. I generally don't go anywhere that getting stuck isn't as simple as jacking the truck up and flopping it over, or adding dirt/rocks under the tires, or strapping on mud chains on for swampy conditions.

Mud rated V-bar tire chains are golden in mud. Not nice because they tear up the earth. Perfect for farms and flooded roads. Very cheap. Just don't use them at off road parks, they turn good trails into pits.

Lights:

No idea, maybe a pair of KC 150 watt.

Snorkle: No. No way. Not that kind of build. I will make sure my drivetrain breathers are up high.

Other:

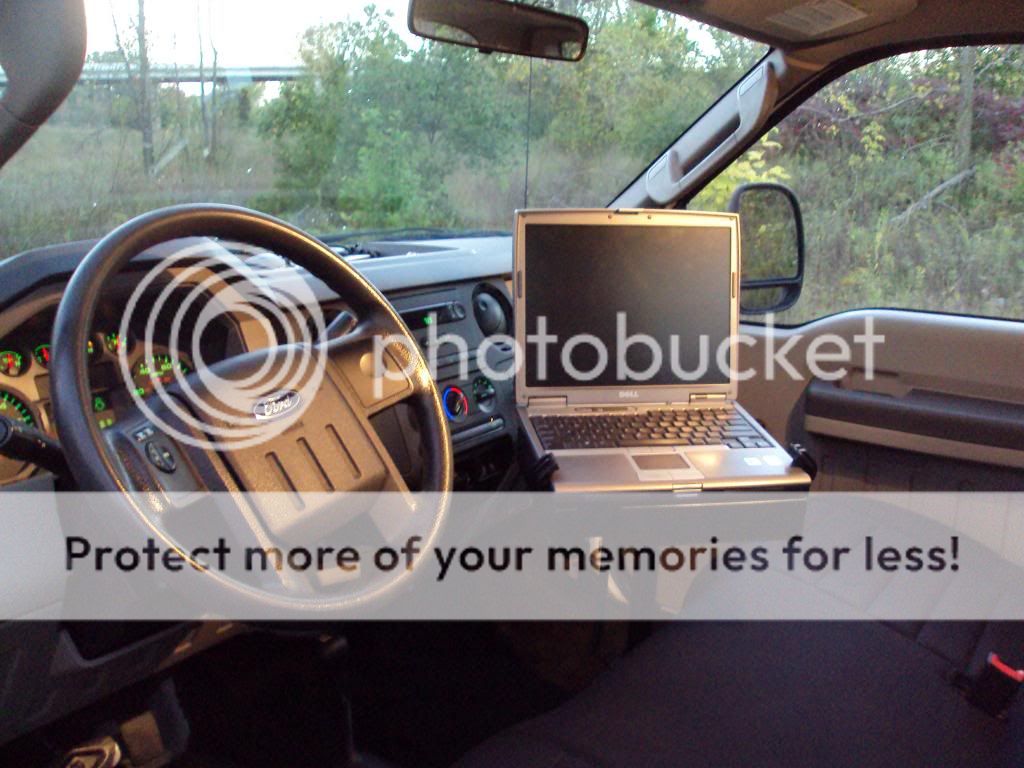

-Delorme GPS running on a HP mini. I had a Ram mount. It was ok. I think I'm going to use a Ram base, but fab up my own platform.

-Galaxy CB, Whip on the bed.

-bug deflector, not sure what brand

-bed liner, no ideas

-2 extra G31 batteries mounted in the bed. I'll use a manual swing switch to parallel them to the truck as needed. No fancy electronics for me, those allways fail to turn off, leaving me stranded. Chances are I'll only connect 1 of those 31's up. The other battery will just be a loose spare, worst case senerio.

Looks like I have some work to do. Later.

Buliwyf.

So I'm looking to start a new build along the same practical camping, mild offroad, and rural highway travel alot of others here seem to embrace. I'm envious of alot of the builds here. It's nice to see tuned up trucks for a real practical purpose. Not just huge lifted show queens. (I'm ok with those, just not my style)

Hopefully I can add my experience to truck tech threads. I was a Master tech for a very short period of time before I became a generator tech many years ago.

Anyways I'm buying a Superduty this fall when prices drop as the next year models come out and fuel prices are usually high driving demand down. Not sure if I'm buying new or buying used at this point. Depends on if I can get a deal on a new truck. I can buy a fairly decent used truck for the cost of depreciation on a new one.

Lucky for me I don't need a daily driver. I have a work Van I take home that's provided by my employer. So I can make some consessions towards something a bit more aggressive than most people. Fuel economy deosnt really matter for example. I only fill my cars tank twice a month or less. Often my company vehicle can e used on my way home for most of my chores. And I allready own a small car for "boring adventureless" travel.

So onto the build plan, any advice is appreciated:

The truck -I'm starting with a Ford Superduty F250/F350. Also staying with XL model work trucks. Manual locks and windows. Nothing to fail, nothing to spaz out and lock me outside my truck on a cold day. Buying a used truck with cash is a nice idea, but given my lifestyle, a brand new truck could last me 20+ years easy.

This kind of truck is what I'll be checking out over the next three months:

New or slightly used:$27k-35k

Or the same type of truck used, year 2000 and up with less than 100,000 miles. These are usually around $10k in my area and often in very good shape.

Since I'm only looking at white base model work 4x4's, many of these used trucks come with torn steering wheels or seats. Who hasn't jumped into their work truck with a sharp screwdriver in thier pocket? That makes them impossible to sell to "normal people". I usually add seat covers and can replace a steering wheel easy enough. I'll most likely replace the brakes with thick Napa rotors and and if I need to, eventually rebuild the transmission. But plenty of city/county trucks see light use compared to a plow truck or daily driver. Just have to know what to look for. The tansmission appears to be the weak link of these trucks. But trans shops are getting good at repairing them.

My needs require:

-Dana 60 front axle. No 1998-2001's with Dana 50's please.

-Sterling/Visteon 10.5" rear end. Which, I imagine, becomes a 10.25 when I regear it.

-Manual hubs, manual transfer case. Old school tough.

-XL interior. Less to break, rubber floors like mud.

-No engine mods, no lifted trucks, no project truck like this. (Usually a bad sign when buying used)

If I buy new, I want the F250. I prefer it's vacuum boost brakes over the F350's hydro boost. The F350 requires less effort to stop with a trailer, but you can feel it tug on the powersteering pump when offroad or manuvering trailers in parking spots. The F250 is cheaper to insure and license as well and I only tow up to 10,000 pounds, never more.

Even though the F250's come with the smaller "5th wheel trailer height" blocks in the rear, I'll be swapping those out soon enough anyways.

Suspension:

BDS 4" would be nice, but overkill.

A 2" leveling kit and 305 sized tires (33") would suit my needs as well. But when you add an adjustabe track bar to get the front end perfect, the overall cost is similar to a complete 4" system. I may not add the 4 link, it's about a $500 option. But it's probally worthwhile.

[

Drivetrain:

Detroit Locker in the rear. I've never had problems with the fullcase Detroit in heavy fullsize trucks. Actually more predictable than the Ford LSD ( I shimmed it tight and used no friction modifier) I used in a previous truck. I like how these ratchet off road in turns. I don't like constantly switching off an ARB. And the Detroit works great, for me, in alot of places that it isn't wise to completely lock an axle. I love being able to gently craw through off road sections. I am not the type to use momentum often. So if that means investing in lockers, and/or stopping to put mud chains on, so be it.

Open diff up front, or if the budget allows an Ox selectable locker up front. I'd run a long Ox cable to the frame, not to the cab. Then I'd use the electric solenoid kit on the frame to actuate the ox locker. Easier, cleaner, cable run that way. A simple cheaper Detroit up front is tempting. But only if i rarely need 4wd on the street in snow. With a Detroit in the rear, my experience is that it's critical to be in 4wd when there is not pavement showing. So open or selectable is the way I need to go I think up front.

No need for fancy axle shafts. Allready running 1ton beef. I may need to a CV stle driveshaft to get rid of vibration with a short lifted truck, but that's unlikely. 4" is barely taller than stock overall.

Engine:

Stock. Fords have plenty of grunt as long as they are geared proper. 300HP is plenty.

I'm after the 6.2L or 5.4L gas engines.

I'm a hardcore diesel guy. But I have enough experience with those to know they won't suit my needs for this build. Extra weight and extra up front cost. I don't tow that often. And I usually can acheive 8-9 mpg, with a gas engine, pulling 9,000 pound generator trailers.

Recovery gear:

The Jeep had a winch. I loved it. But it's not needed with this build. I see a ton of salt/snow so a winch would be repaired more often than used. Not to mention, there is nothing within 100' of a Superduty anytime it actualy deos get stuck. At least never anything that can handle 10,000 pounds of pull.

So I better plan on not being winchable. Shovel, highlift, and wheel grabber for the high lift. I generally don't go anywhere that getting stuck isn't as simple as jacking the truck up and flopping it over, or adding dirt/rocks under the tires, or strapping on mud chains on for swampy conditions.

Mud rated V-bar tire chains are golden in mud. Not nice because they tear up the earth. Perfect for farms and flooded roads. Very cheap. Just don't use them at off road parks, they turn good trails into pits.

Lights:

No idea, maybe a pair of KC 150 watt.

Snorkle: No. No way. Not that kind of build. I will make sure my drivetrain breathers are up high.

Other:

-Delorme GPS running on a HP mini. I had a Ram mount. It was ok. I think I'm going to use a Ram base, but fab up my own platform.

-Galaxy CB, Whip on the bed.

-bug deflector, not sure what brand

-bed liner, no ideas

-2 extra G31 batteries mounted in the bed. I'll use a manual swing switch to parallel them to the truck as needed. No fancy electronics for me, those allways fail to turn off, leaving me stranded. Chances are I'll only connect 1 of those 31's up. The other battery will just be a loose spare, worst case senerio.

Looks like I have some work to do. Later.

Buliwyf.

Last edited: