jh504

Explorer

I posted a while back about a pirogue that I built for very shallow water paddleing. It is a great little boat but now it is time to move up the power spectrum a little bit. I am planning on building a 15' skiff based on a duck hunting platform. It will hopefully have about 5" of draft at 600lb load and it will be powered by about a 35-40hp mud motor or surface drive. For those of you who havnt spent much time in the bayou here is a pretty cool link to the kind of motor I am talking about: http://www.youtube.com/watch?v=ZV8FyHrR59M&feature=related . It will basically be a go anywhere boat and can take up to a 1000lb payload. I will be using it for duck hunting, setting crawfish and crab traps, and exploring the swamp land. I should be getting the plans soon and probably starting construction after Christmas. I will have the details of the build on this thread.

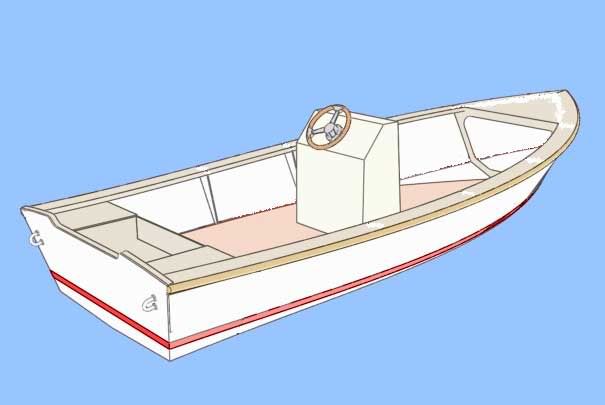

Here is a pic from the plans I will be using:

Here is a pic from the plans I will be using: