Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Great tool for building your own parts for your rig

- Thread starter The_Goob

- Start date

Agreed! I’ve made dozens of things with mine, including:

Hi-lift mount

Under seat air compressor mount

Under seat radio mount

Mounts for drawer glides for cargo shelf

Wheel well mounts for ammo cans

Third brake light mount

Solar panel brackets

Trailer tail light brackets

If you haven’t already, make a tighter opening for the lower die and you can get pretty sharp bends in thinner stuff. I commonly work with 1/8” strip because it is easy to buy 1/8x12” - easy to buy and easy to work with vs plate. I made a flat bar die that sits on top of the lower die and has 3/4” key stock welded down with a 3/4” gap. It bends 1/8 or 3/16 at a 3/16 radius (maybe a bit smaller) and is by far my most useful addition. Similar to their adjustable lower die but never needs adjusting.

Hi-lift mount

Under seat air compressor mount

Under seat radio mount

Mounts for drawer glides for cargo shelf

Wheel well mounts for ammo cans

Third brake light mount

Solar panel brackets

Trailer tail light brackets

If you haven’t already, make a tighter opening for the lower die and you can get pretty sharp bends in thinner stuff. I commonly work with 1/8” strip because it is easy to buy 1/8x12” - easy to buy and easy to work with vs plate. I made a flat bar die that sits on top of the lower die and has 3/4” key stock welded down with a 3/4” gap. It bends 1/8 or 3/16 at a 3/16 radius (maybe a bit smaller) and is by far my most useful addition. Similar to their adjustable lower die but never needs adjusting.

Hillbilly Heaven

Explorer

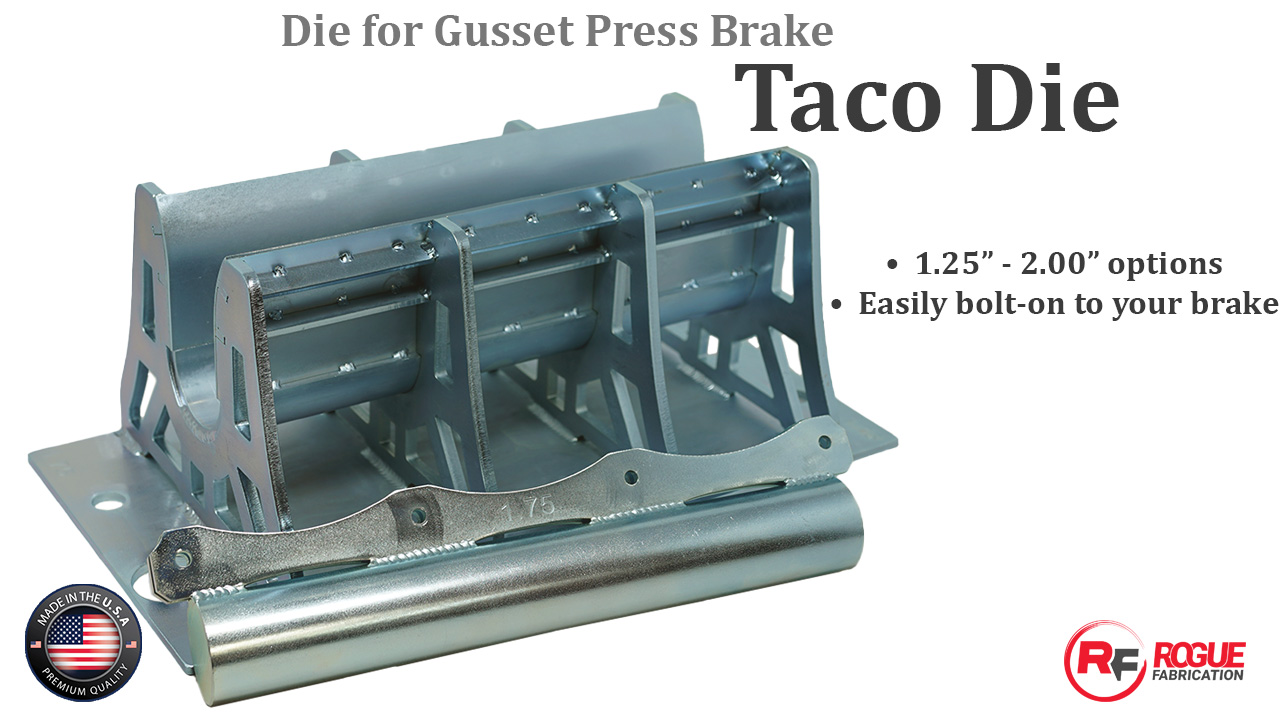

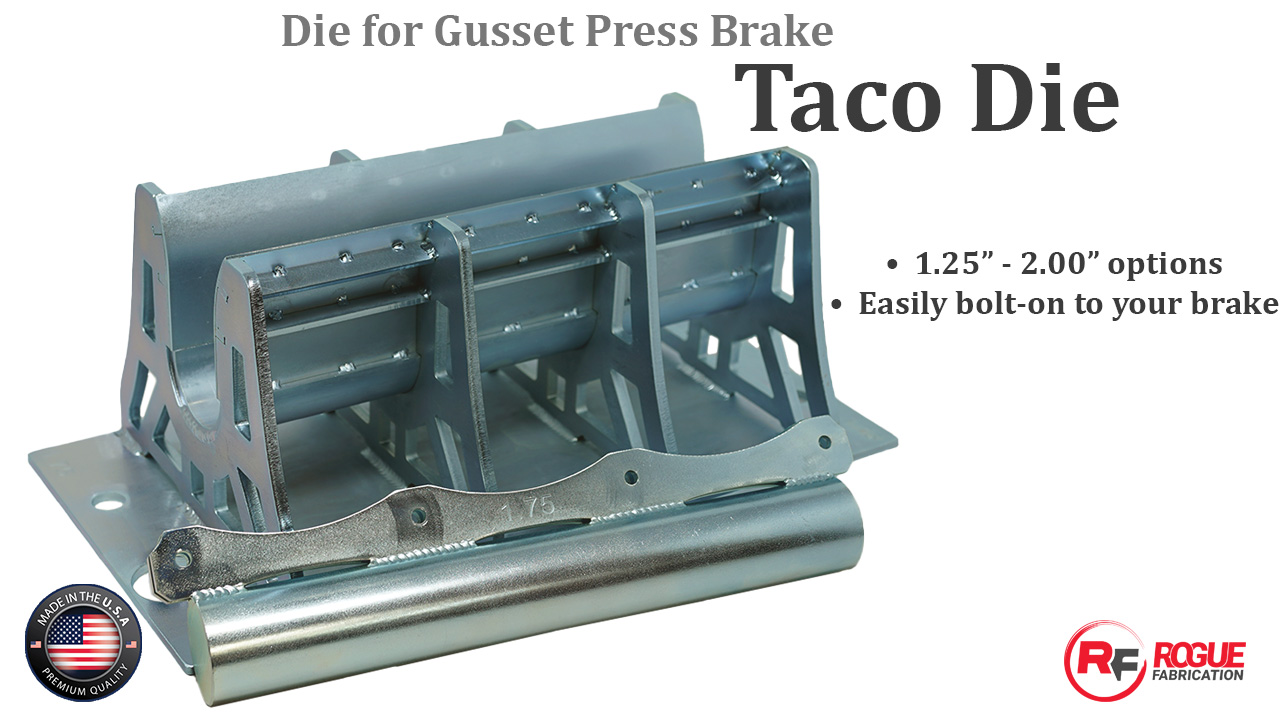

I wished someone beside Rouge Fab made a taco bender die.

www.roguefab.com

www.roguefab.com

Die for Gusset press brake (Taco Die) - Rogue Fabrication

Add more range of capacity to your Gusset Press Brake! Choose any size from the list. They all bolt on to your brake in about 5 minutes. These are designed to work with our Gusset...

www.roguefab.com

www.roguefab.com

I think you could easily get the same effect on the Swag unit simply by welding some round rod onto some 3/4 flat bar and replacing the fingers with it. You might have to customize the lower die, but they appear to intend the die you linked to be a coining die, and that consumes a lot of force, I suspect that with the right lower die opening and depth you could make a good smooth radius by air bending like the Swag does.

The lower die you linked seems to be a bunch of laser cut craziness that adds little or no value to the function of the tool but costs much more to produce.

Is the goal to have tools that make what you want, or tools that look like they belong in a Steampunk shop?

The lower die you linked seems to be a bunch of laser cut craziness that adds little or no value to the function of the tool but costs much more to produce.

Is the goal to have tools that make what you want, or tools that look like they belong in a Steampunk shop?

thebmrust

Active member

Nate, do you have a few pics or video of your mod and some of the results/examples?Agreed! I’ve made dozens of things with mine, including:

Hi-lift mount

Under seat air compressor mount

Under seat radio mount

Mounts for drawer glides for cargo shelf

Wheel well mounts for ammo cans

Third brake light mount

Solar panel brackets

Trailer tail light brackets

If you haven’t already, make a tighter opening for the lower die and you can get pretty sharp bends in thinner stuff. I commonly work with 1/8” strip because it is easy to buy 1/8x12” - easy to buy and easy to work with vs plate. I made a flat bar die that sits on top of the lower die and has 3/4” key stock welded down with a 3/4” gap. It bends 1/8 or 3/16 at a 3/16 radius (maybe a bit smaller) and is by far my most useful addition. Similar to their adjustable lower die but never needs adjusting.

Similar threads

- Replies

- 0

- Views

- 572

- Replies

- 32

- Views

- 6K

- Replies

- 9

- Views

- 3K

- Replies

- 12

- Views

- 3K