Ever since my suspension lift (OME) , I get a slight wagging feeling when driving on roads where there is lots of up and down wheel movement. Corrugation does not cause this effect, because the vertical wheel movement is small, even if high frequency.

This morning I after driving behind a standard 4x2 Fortuner I visually compared the movement of the axle with the bumper on the vehicle, and was shocked to see how much movement there really is. That's when I decided to measure the angle of the Panhard rod, and see how the suspension lift influenced that. Before I start with my part of the explination, I'll post something on Panhard rods and how the work.

An example of a Panhardt rod.

While the purpose of the suspension of an automobile is to allow the wheels to move vertically with respect to the body, it is undesirable to allow them to move forward and backwards, or from side to side. It is this latter movement that the Panhard rod is designed to prevent. It is a simple device, consisting of a rigid bar running sideways in the same plane as the axle, connecting one end of the axle to the car body or chassis on the opposite side of the vehicle. The bar is attached on either end with pivots that permit it to swivel upwards and downwards only, so that the axle is, in turn, allowed to move in the vertical plane only. This does not effectively locate the axle longitudinally, therefore it is usually used in conjunction with trailing arms which locate the axle in the longitudinal direction. This arrangement is not usually used with a leaf spring suspension, where the springs themselves supply enough lateral rigidity, but only with coil spring suspensions.

When the suspension is lifted, through spacers or longer coil springs, the angle of this rod changes,a nd the axle will physically be moved to the one side of the vehicle because of the "Shorter" (in the horizontal plane) Panhardt rod. This is a problem than can easily be overcome by buying or making a longer, or even an adjustable Panhardt rod.A bigger problem though is that the horizontal movement of the mounting points due to the vertical movement of the chassis increases with increased angles. Let me explain with images:

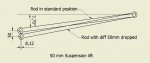

This is the position of the Panhardt rod in a standard suspension when the vehicle is unloaded on a level surface:

Fig 1

Now lets look at the horizontal movement with vertical wheel travel:

If the diff move down 50mm, the entire diff wil move 5.5mm to the right of the car.

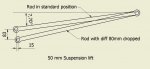

Ok, now lets consider a case with a 50mm suspension lift and 50mm wheel travel.

But, 50mm wheel travel is nothing. The Fortuner has more than 250mm (yes, I know thats not a lot) in standard form. It will most probably never be used on a road, but 80mm wheel travel is not uncommon on normal roads (pot holes etc....)

Fig 4.

So, 80mm downward travel on a 50mm suspension lift will move the axle 15mm to the right of the vehicle. Considering that this take place at high speed, it WILL cause instability and body roll. Also consider that at this point the diff is 20mm offset in the vehicle. (Add the 5mm offset you got with the lift to the 15mm the axle moves horizontally due to vertical movement).

You will also fell it much more when the left rear wheel go over imperfections, because the Panhard rod mounts on the axle on the left side of the vehicle. It is typically felt when driving into a driveway at an angle.

The solution:

1. Lift the Panhard rod mounting on the axle,

2. Drop the Panhard rod mounting on the vehicle.

A longer Panhard will center the axle on the vehicle, but wont' correct the movement. I plan to manufacture a bolt-on bracket to correct the angle of the rod, and even reduce it a bit form standard guise, which I believe will make a massive difference to the stability of the vehicle.

Any comments - what to look out for, and what have you done?

This morning I after driving behind a standard 4x2 Fortuner I visually compared the movement of the axle with the bumper on the vehicle, and was shocked to see how much movement there really is. That's when I decided to measure the angle of the Panhard rod, and see how the suspension lift influenced that. Before I start with my part of the explination, I'll post something on Panhard rods and how the work.

An example of a Panhardt rod.

While the purpose of the suspension of an automobile is to allow the wheels to move vertically with respect to the body, it is undesirable to allow them to move forward and backwards, or from side to side. It is this latter movement that the Panhard rod is designed to prevent. It is a simple device, consisting of a rigid bar running sideways in the same plane as the axle, connecting one end of the axle to the car body or chassis on the opposite side of the vehicle. The bar is attached on either end with pivots that permit it to swivel upwards and downwards only, so that the axle is, in turn, allowed to move in the vertical plane only. This does not effectively locate the axle longitudinally, therefore it is usually used in conjunction with trailing arms which locate the axle in the longitudinal direction. This arrangement is not usually used with a leaf spring suspension, where the springs themselves supply enough lateral rigidity, but only with coil spring suspensions.

When the suspension is lifted, through spacers or longer coil springs, the angle of this rod changes,a nd the axle will physically be moved to the one side of the vehicle because of the "Shorter" (in the horizontal plane) Panhardt rod. This is a problem than can easily be overcome by buying or making a longer, or even an adjustable Panhardt rod.A bigger problem though is that the horizontal movement of the mounting points due to the vertical movement of the chassis increases with increased angles. Let me explain with images:

This is the position of the Panhardt rod in a standard suspension when the vehicle is unloaded on a level surface:

Fig 1

Now lets look at the horizontal movement with vertical wheel travel:

If the diff move down 50mm, the entire diff wil move 5.5mm to the right of the car.

Ok, now lets consider a case with a 50mm suspension lift and 50mm wheel travel.

But, 50mm wheel travel is nothing. The Fortuner has more than 250mm (yes, I know thats not a lot) in standard form. It will most probably never be used on a road, but 80mm wheel travel is not uncommon on normal roads (pot holes etc....)

Fig 4.

So, 80mm downward travel on a 50mm suspension lift will move the axle 15mm to the right of the vehicle. Considering that this take place at high speed, it WILL cause instability and body roll. Also consider that at this point the diff is 20mm offset in the vehicle. (Add the 5mm offset you got with the lift to the 15mm the axle moves horizontally due to vertical movement).

You will also fell it much more when the left rear wheel go over imperfections, because the Panhard rod mounts on the axle on the left side of the vehicle. It is typically felt when driving into a driveway at an angle.

The solution:

1. Lift the Panhard rod mounting on the axle,

2. Drop the Panhard rod mounting on the vehicle.

A longer Panhard will center the axle on the vehicle, but wont' correct the movement. I plan to manufacture a bolt-on bracket to correct the angle of the rod, and even reduce it a bit form standard guise, which I believe will make a massive difference to the stability of the vehicle.

Any comments - what to look out for, and what have you done?