I just picked up an '88 skamper pop up 100S. Its the +- ten foot long version.

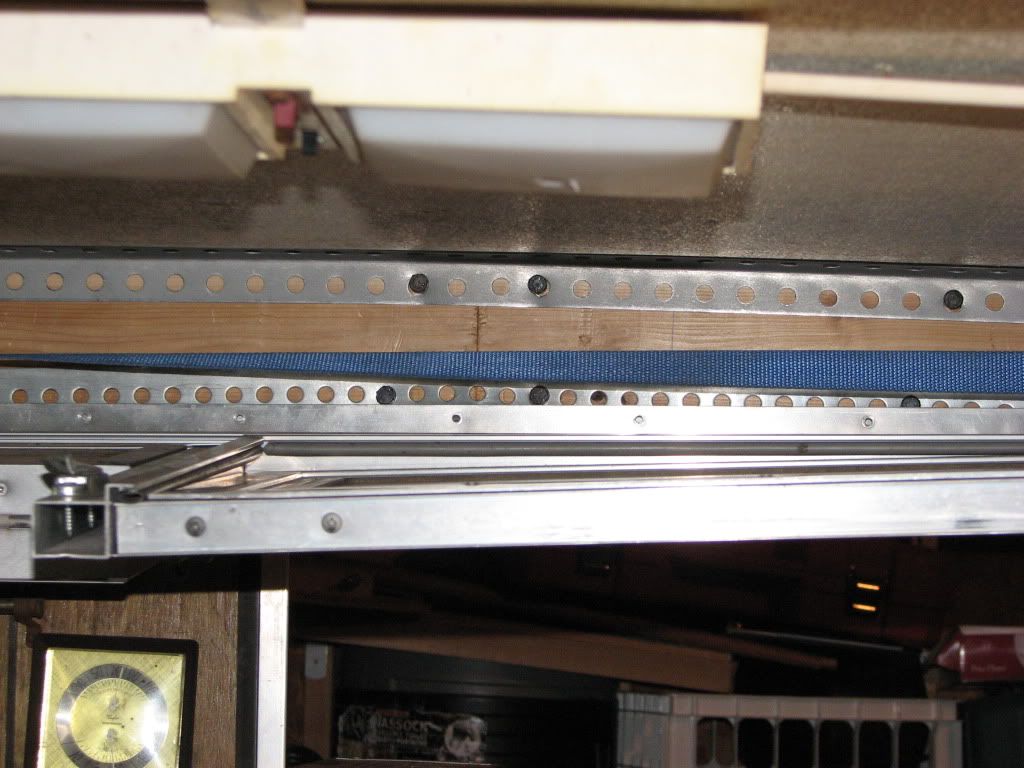

The last owner tried to rebuild the roof and failed thouroughly. I might paste it back together for a little bit, but really it needs the roof rebuilt from scratch.

If someone has done this, or knows about threads, your direction would be appreciated.

I'm tempted to build it out of aluminum C- channel for strength and weight, but I am a carpenter by trade, so if I can do it out of wood, that will be easiest.

I haven't figured out what all works or doesn't, but the price was right.

Can anyone steer me towards the right tie down scenario for my Dodge?

Thanks a lot. Hoping to have this thing cleaned up by the weekend.

Dave

The last owner tried to rebuild the roof and failed thouroughly. I might paste it back together for a little bit, but really it needs the roof rebuilt from scratch.

If someone has done this, or knows about threads, your direction would be appreciated.

I'm tempted to build it out of aluminum C- channel for strength and weight, but I am a carpenter by trade, so if I can do it out of wood, that will be easiest.

I haven't figured out what all works or doesn't, but the price was right.

Can anyone steer me towards the right tie down scenario for my Dodge?

Thanks a lot. Hoping to have this thing cleaned up by the weekend.

Dave