Today was just one of those days where I just stood back and looked, measured, and farted around with some different ideas...

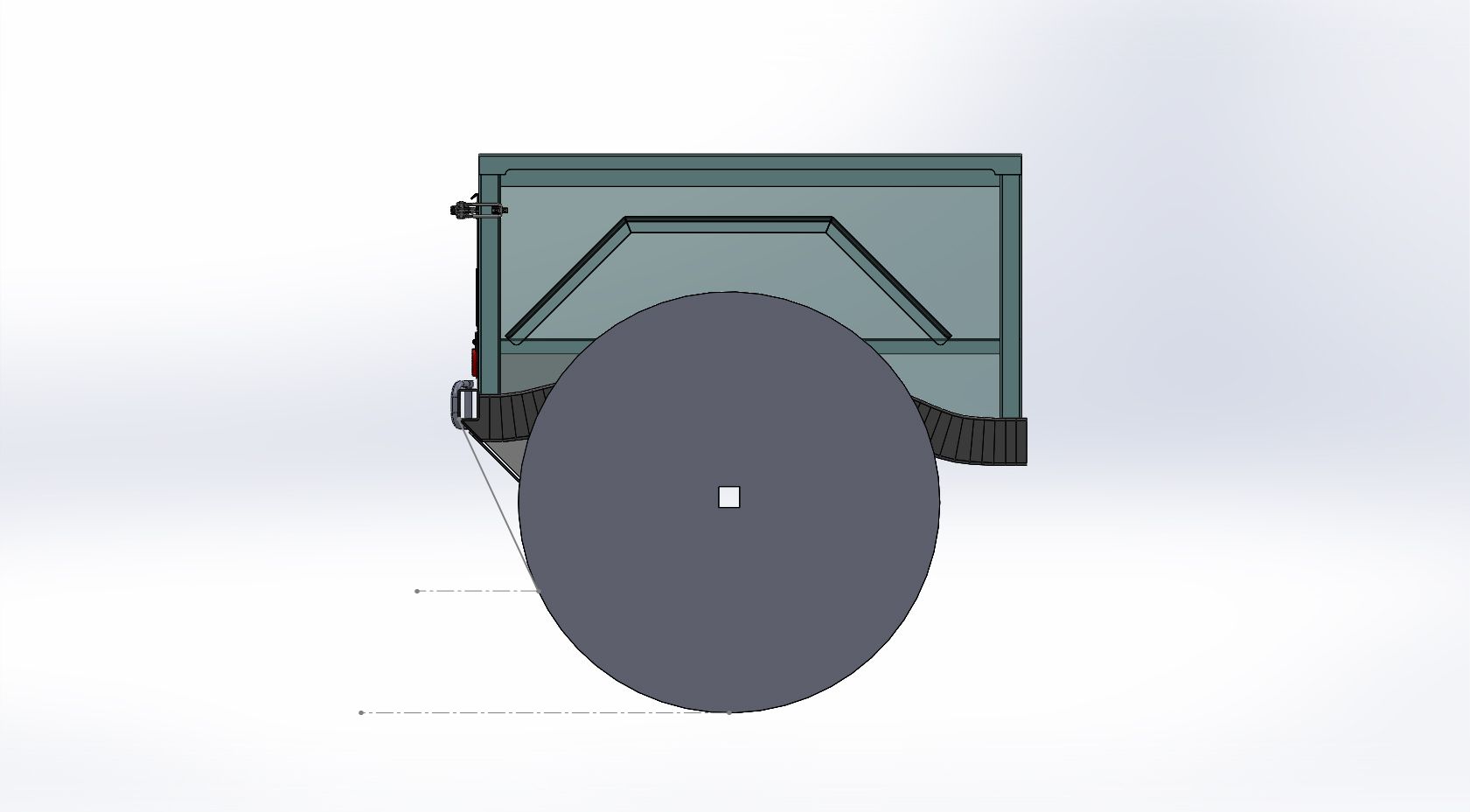

This is going to be the final rearward position of the bumper. The frame is going to be bobbed about 18" or so. I will need to drop the bumper about 2.5" I believe. I will be trying to do this similar to the front bumper where I can get the bumper into place before completely cutting the bumper off. I don't know if this really helps anything, but it can't hurt. The departure angle should be pretty good. The chassis is at full bump right now. I suspect the suspension will be about 5-6" up at ride height.

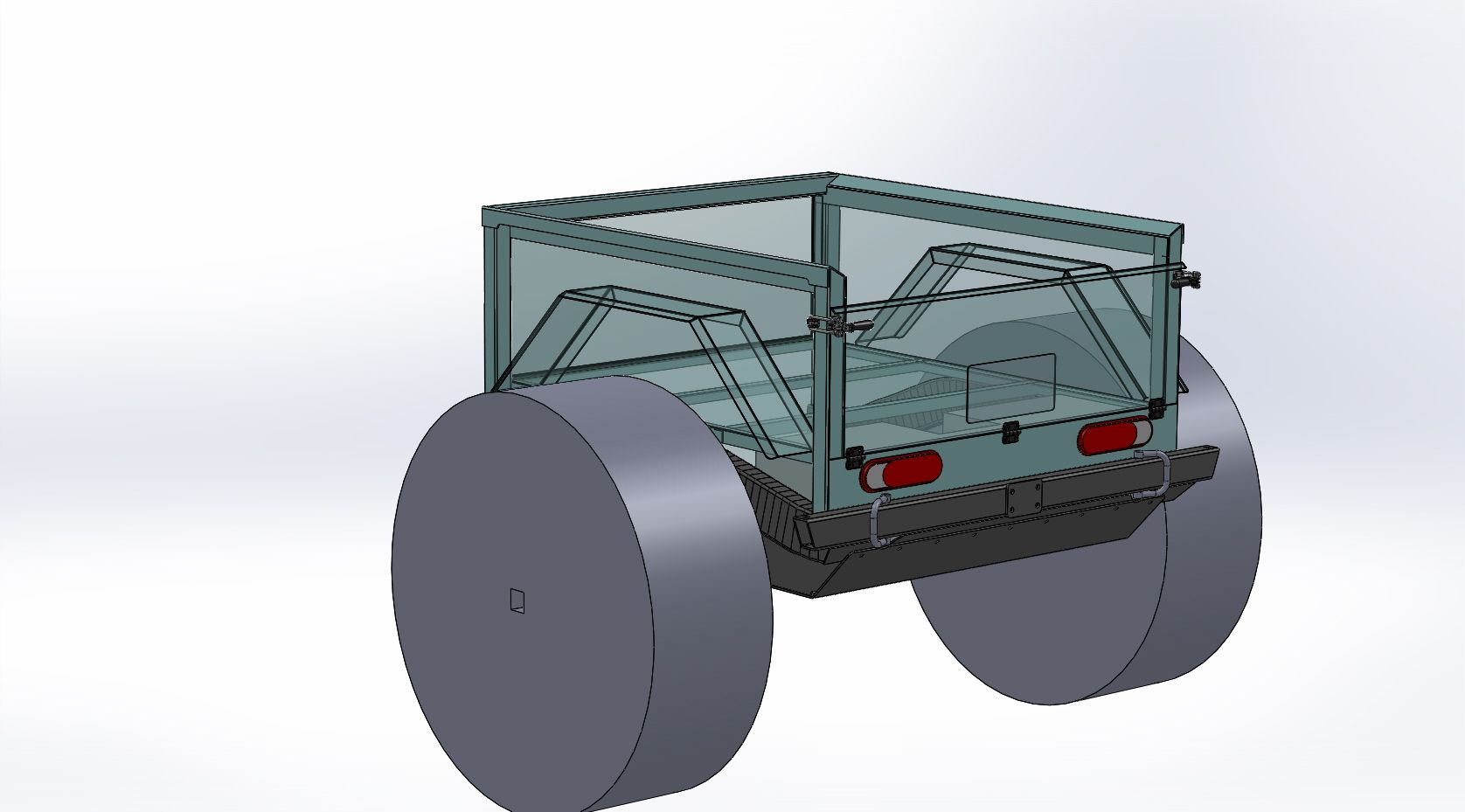

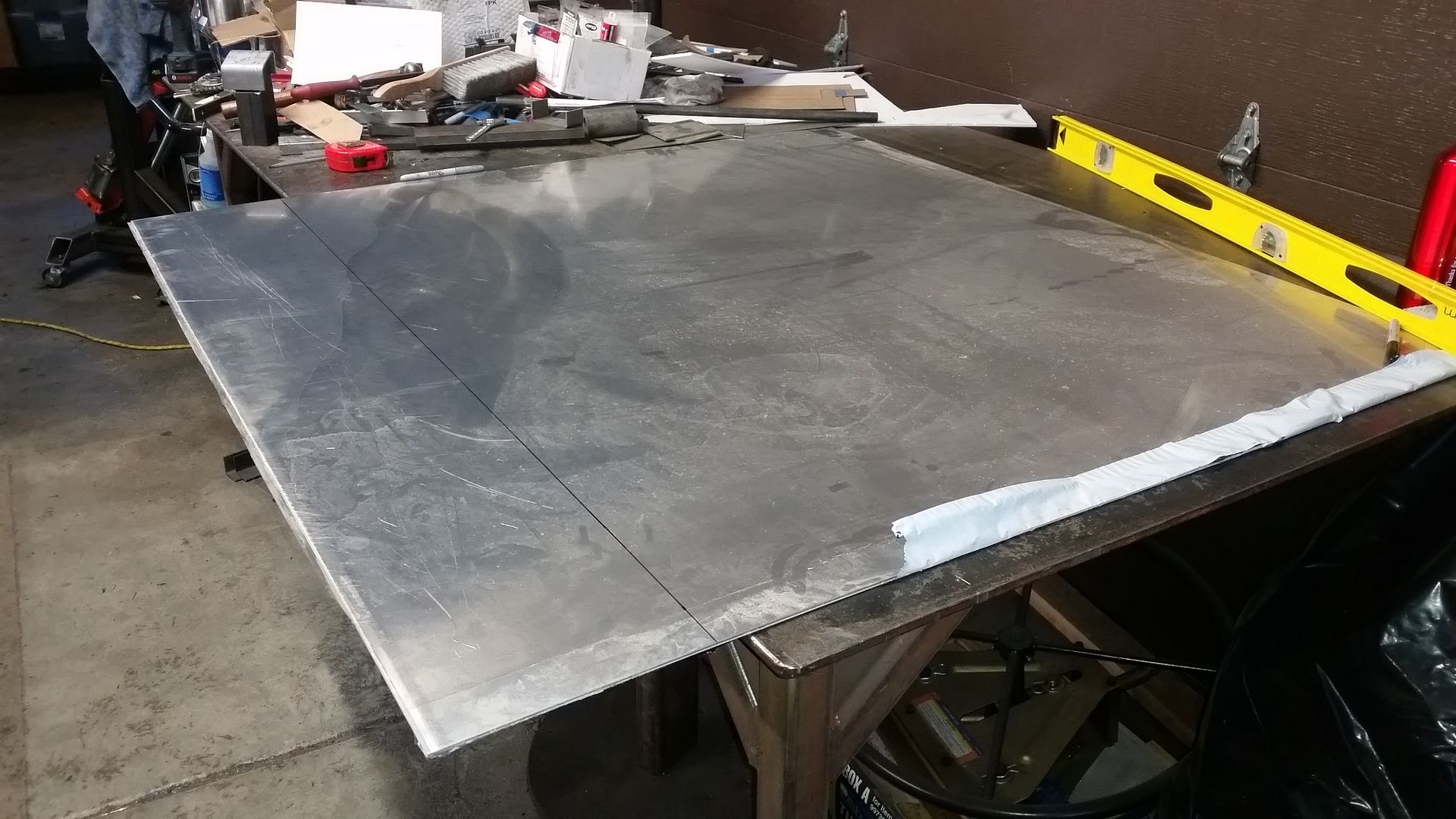

This should give me a bed about 51.5" long depending on how much space I have from the back of the tub to the front of the bed. I think about 1/2" should be enough gap/space?

Here I am just trying to get a better idea of the scale of everything. Originally I thought I wanted the bed to be level with the lip of the rear of the tub. In the end, I think I decided to drop the bed slightly to help make the bed a little obtrusive. I am going to drop the bed about 1.25" below the lip on the back of the tub.

I believe this will leave me with a bed that is about 17-18" deep to the top of the rail. The bed should be about 42" wide and 51.5" long. That seems like a decent amount of space for a guy coming from a flat fender. I should have no problem laying the spare tire down in the bed with room to spare. With a 40" tire I should have almost a foot of extra space.

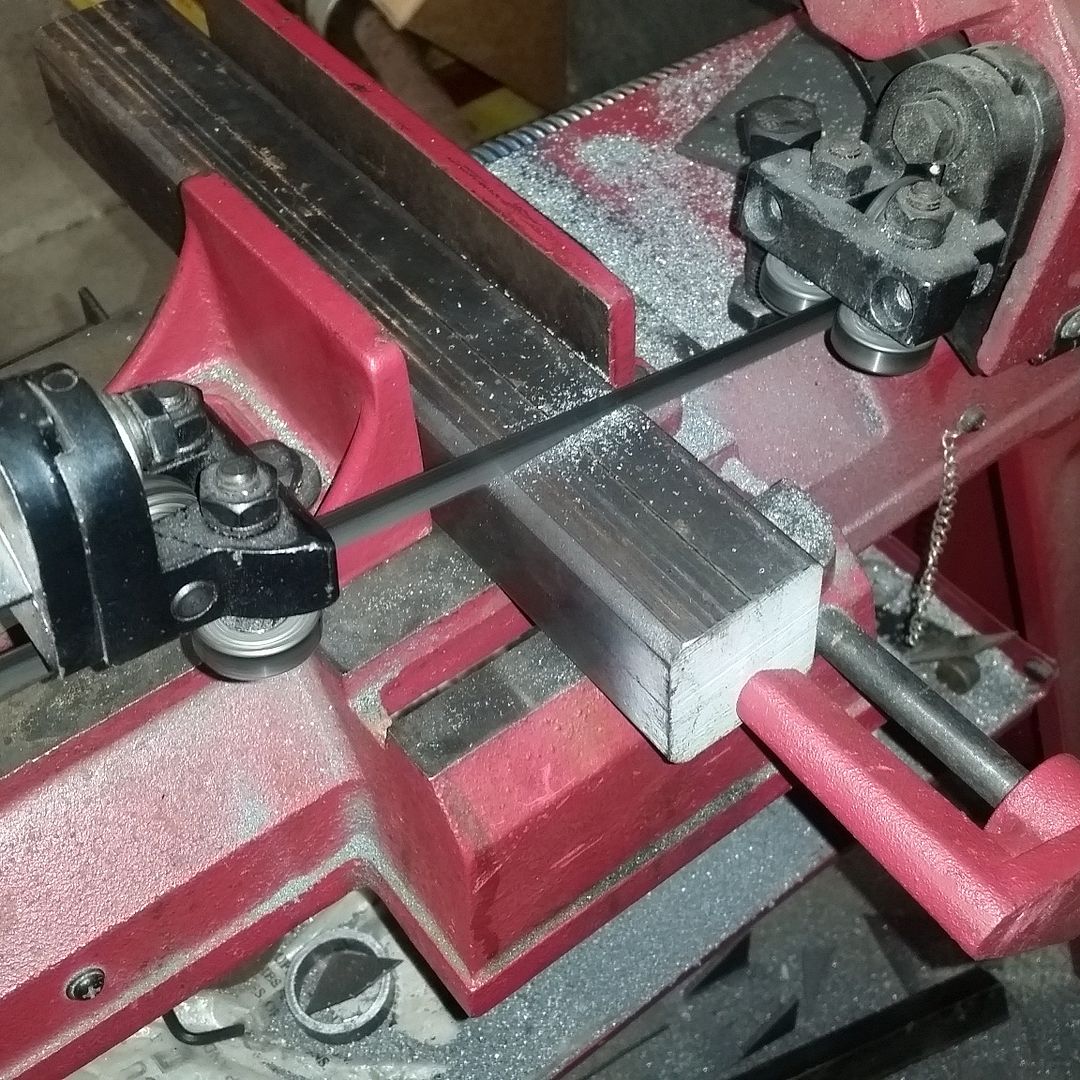

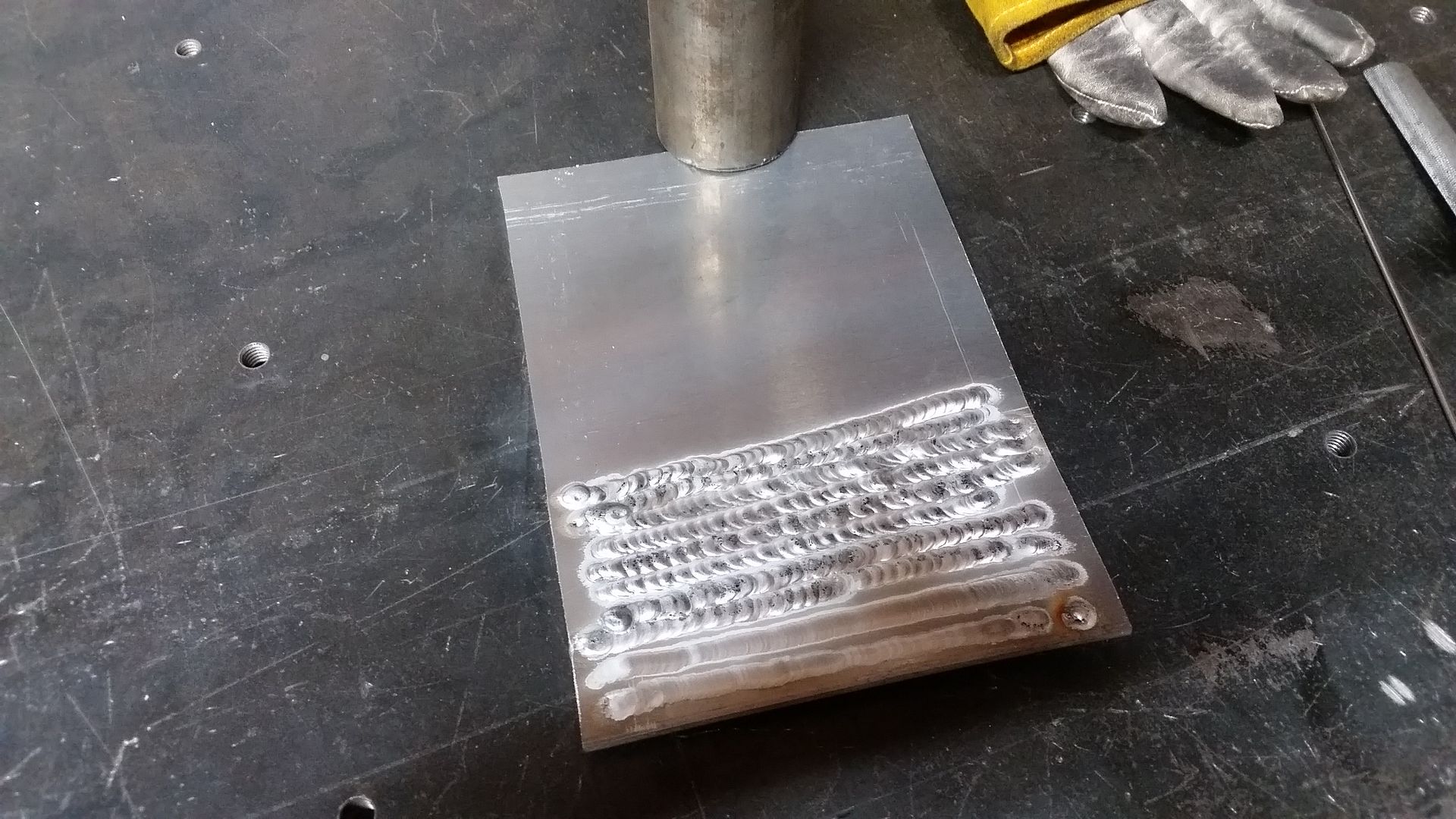

This was my experiment on how to build the bed rail system. The top of the tube as been cut to a 30 degree angle with the a section of what would be the inner wall removed. That should allow a flush surface for inner bed wall to attach to. That would give me a nice perimeter flange to secure the bed wall panel onto.

The tube is 2x2x1/8" wall. I will have those at the 4 corners of the bed. I need to come up with a way to have them easily and cleanly attach to the frame. I don't want the bed to be a completely welded to the frame assembly. I want to be able to remove the bed frame for paint. I believe it will be body color while the frame/bumper will just be black.

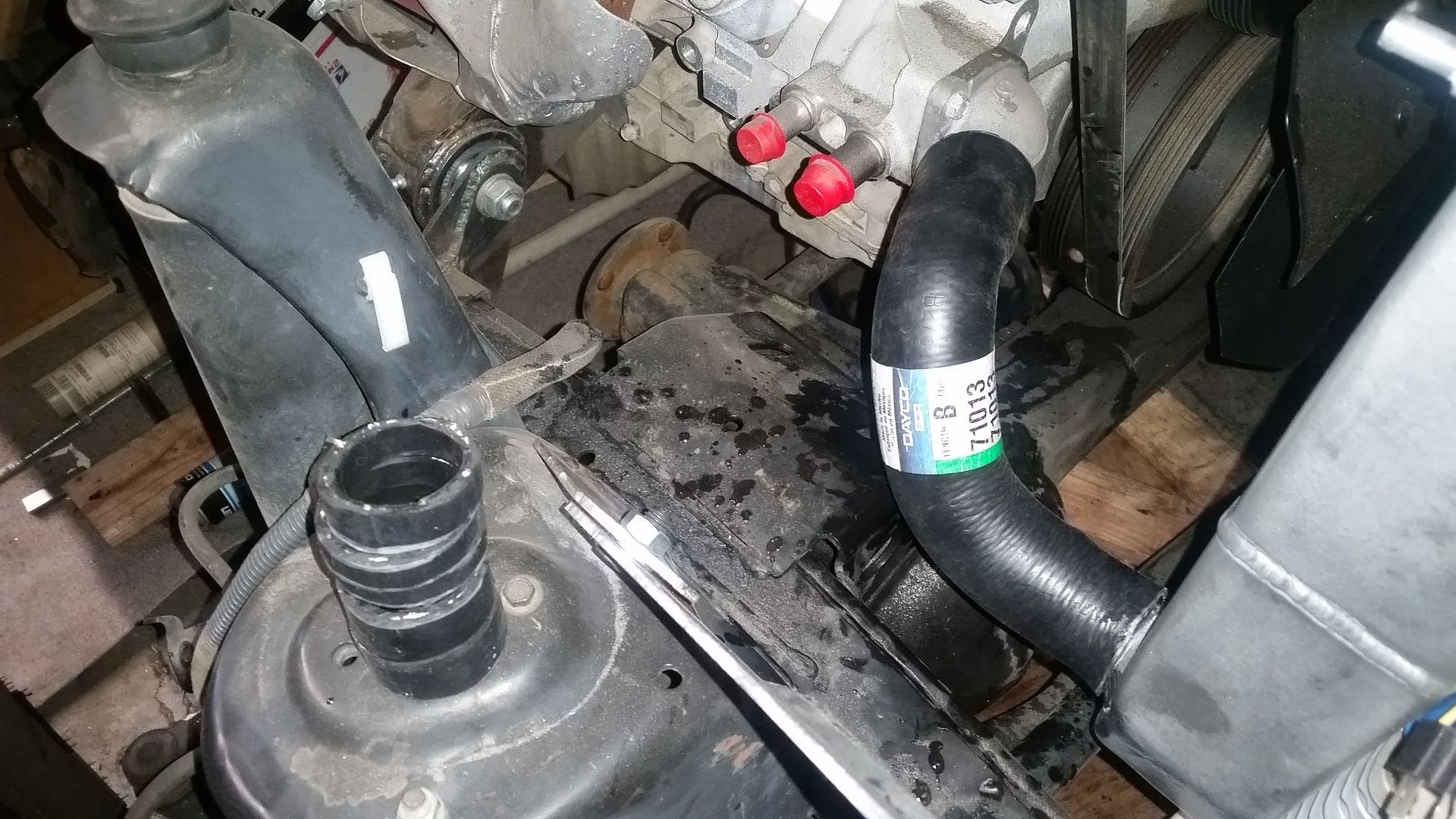

One crazy idea I have is to use one of the vertical bed posts as the fuel filler for the fuel tank. I could french in one of those pop-up motorcycle fuel fillers in the bed rail. Run the fuel down the post. Then french in some kind of 90 bend to the bottom which would turn towards the tank. That would completely hide the filler system?

The top cap is a piece of 5" wide sheet/plate/bar that I formed in my press brake. I think I might shorten up the outer vertical flange a little bit. It looks a bit tall to me. Taking off like 1/4-1/2" might make it look a bit better?