Sticking stuff together with the metal glue gun....

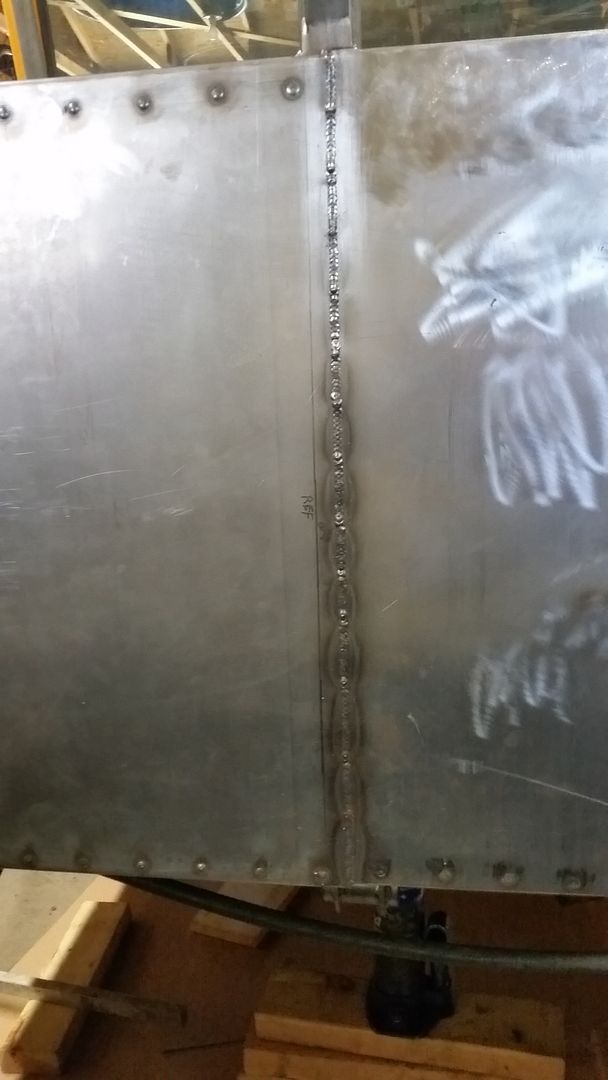

One half the rear wall is welded into place. I used 3/16" holes through the 16 gauge panel material for plug welds with the mig welder. This seems like my favorite size hole for plugs with a mig. On 16th to 16th material the welds lay flat or even slightly negative. With the 16th over 8th the weld stands up a little more and needs to be cut down to be flush.

On that note. I have been trying to be a better metalsmith. Looking at the work of some of the others, I needed to step up my game a little bit. Being able to get that 'no-weld' or 'is that welded' sheetmetal look is a good challenge.

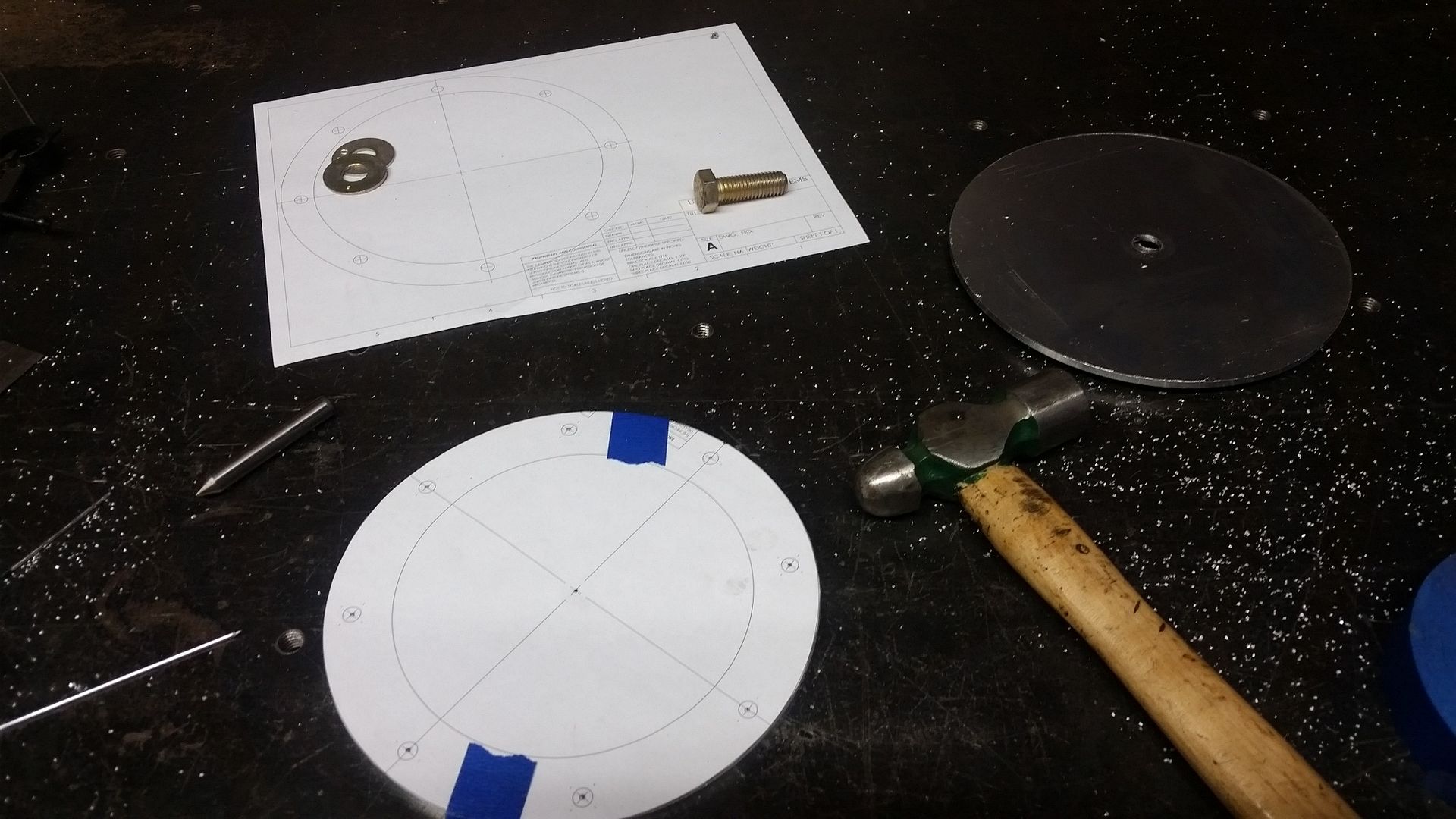

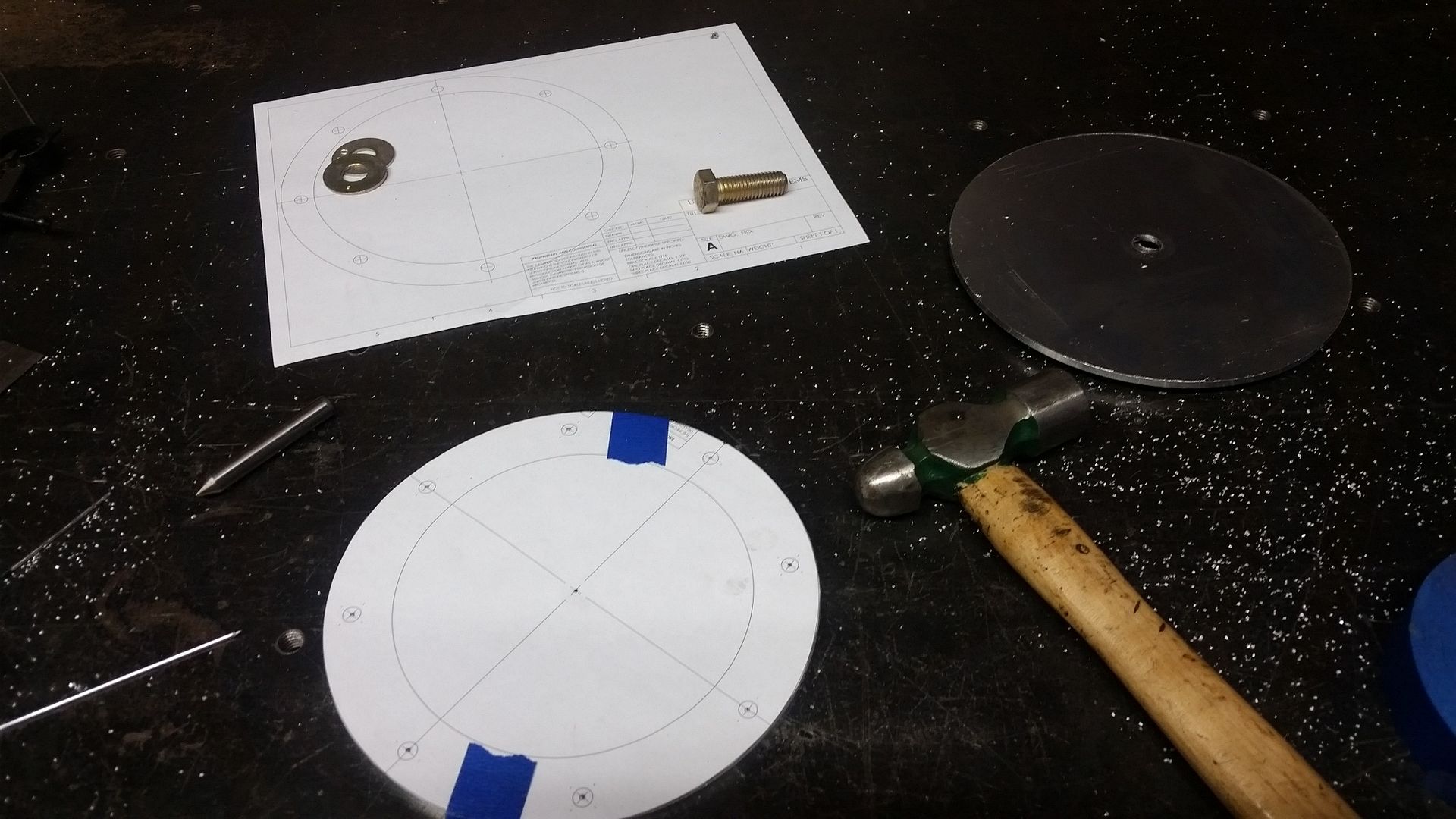

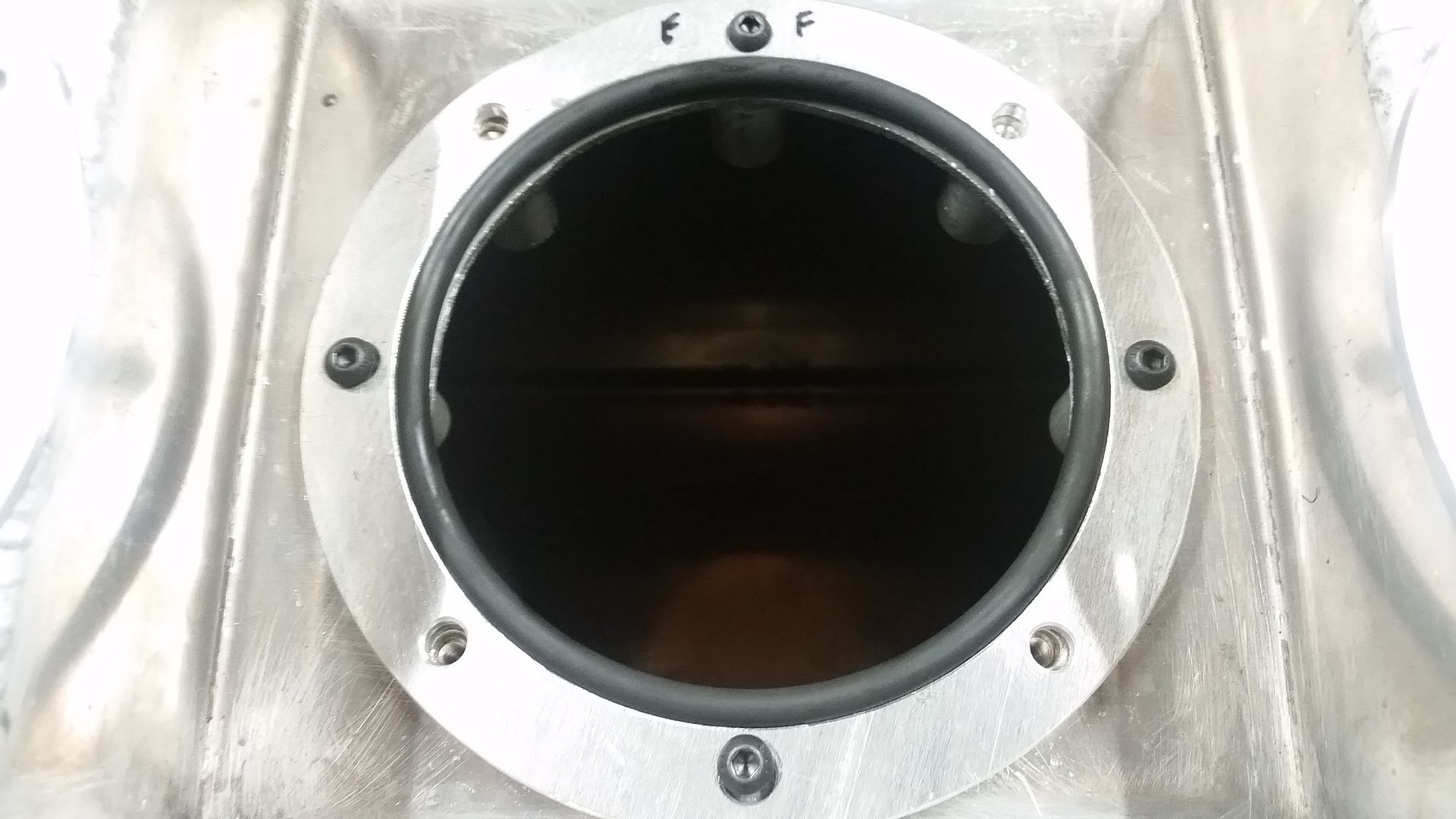

Some misc pics....

This shows the plug welds locations before metal prep.

Close up after metal prep.

This was done with a 2" air grinder ( note: I need a real compressor )

36 grit - 80 grit - Brown scotch - Red scotch - Green scotch.

That seems to be working pretty well. I also wend over each weld location with a body hammer a little bit to try and release any tension at the weld location and lower the material slightly.

That's all for now. Side D tomorrow. After that I think I can start forming the spine for the rear panel bulb seals. I am also going to need to make a few jigs to space things a consistent distance from the outside edge top to bottom with the 1/16 difference from the rear panel overlap.