Metcalf

Expedition Leader

We all are.

Well some of us are.

No offence to some people but some people's "cool stuff" is cooler than others.

I thought I was doing some cool stuff with my 4x4 Vanagon conversion then I checked out some of the things you were working on and I was "maaaan, why didn't I think of that.

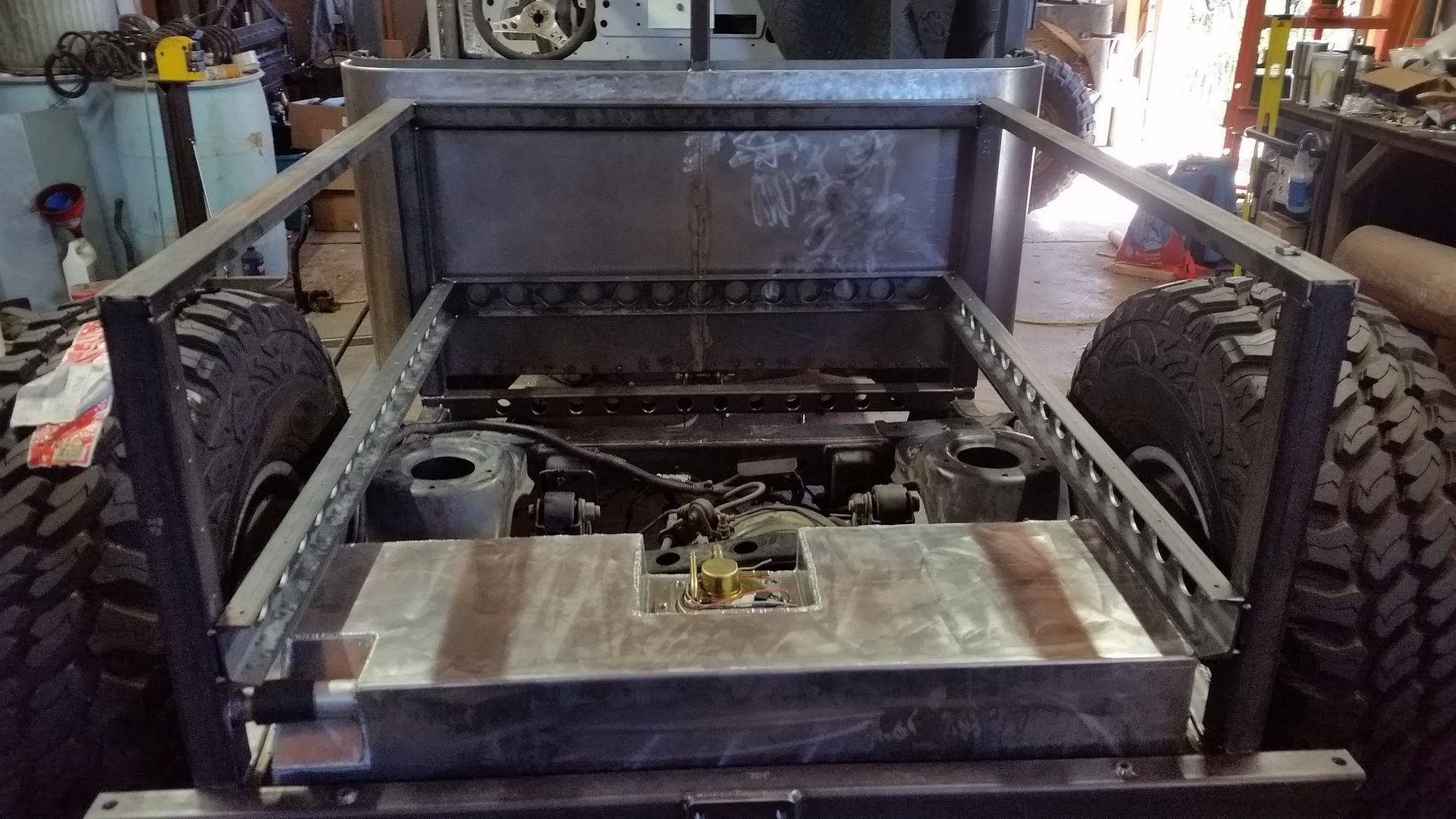

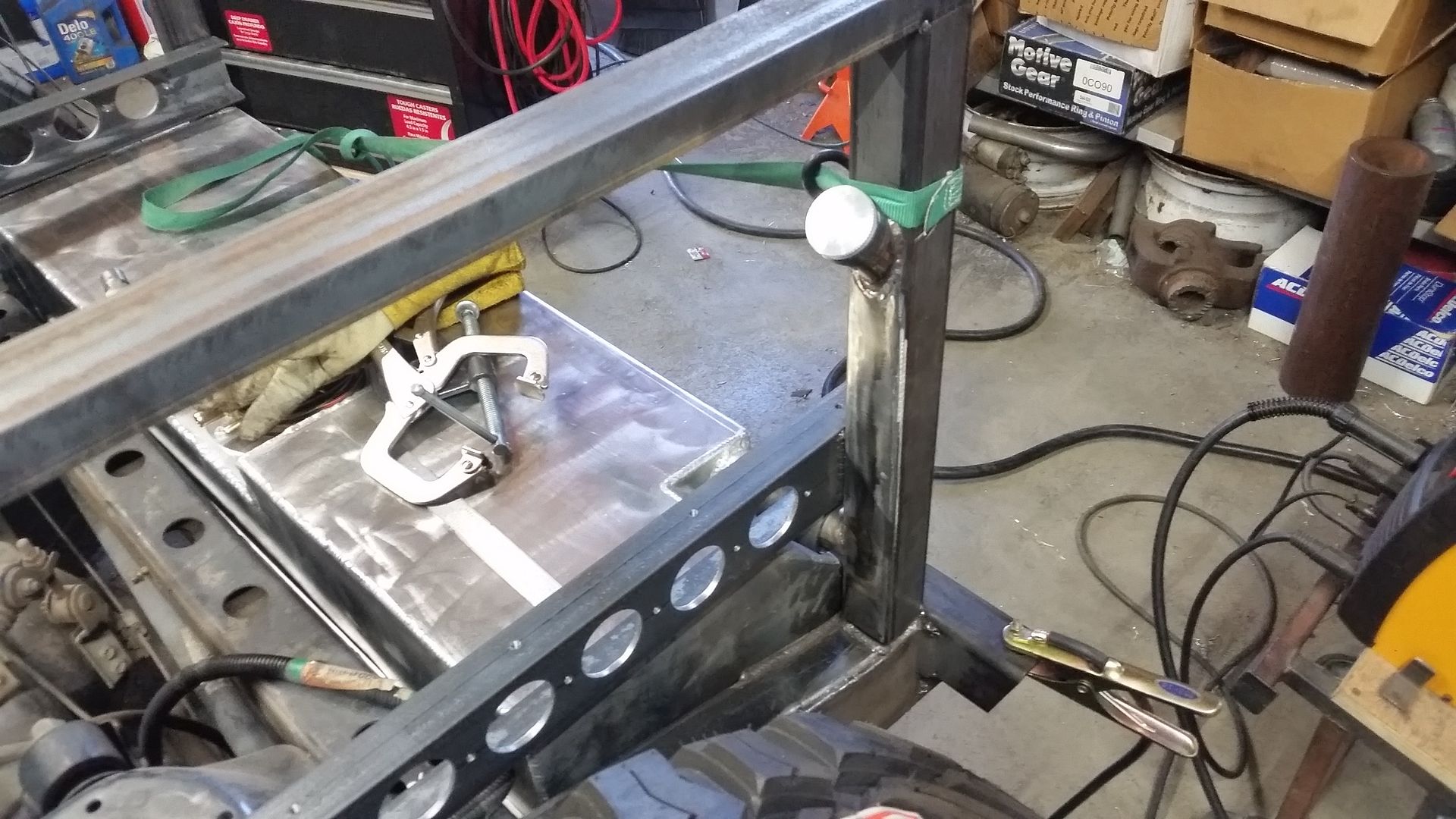

Just got my TIG welder up and running and will be building an aluminum fuel tank sometime soon so I was excited to see the progress on your tank.

You even took the time to show us your progress on learning to weld aluminum.

Again, Thank you. One of my overall goals with these build threads is to get people to close the catalog and get out in the garage to make what you really want. I'm SOOOO tired of seeing the same thing over and over again. This isn't rocket science. Sure, I might be slightly more gifted at it than some, but I feel that everyone can get to where I am. The cost of decent workable tools has come down so much in the last decade or two. The other problem is that I think people are almost afraid to ask questions these days. There is definitely some boards that are worse than others for some of those questions. I always try and answer every question I get and most of the time you don't even need that thick of skin to read my answers. I wish I could poke my nose in every thread, but I just don't have THAT much time. I try and keep up on a few like yours.

Cheers.