My weekend progress...

I was able to get most of the bed roughed in this weekend. Overall I am pretty happy with the proportions.

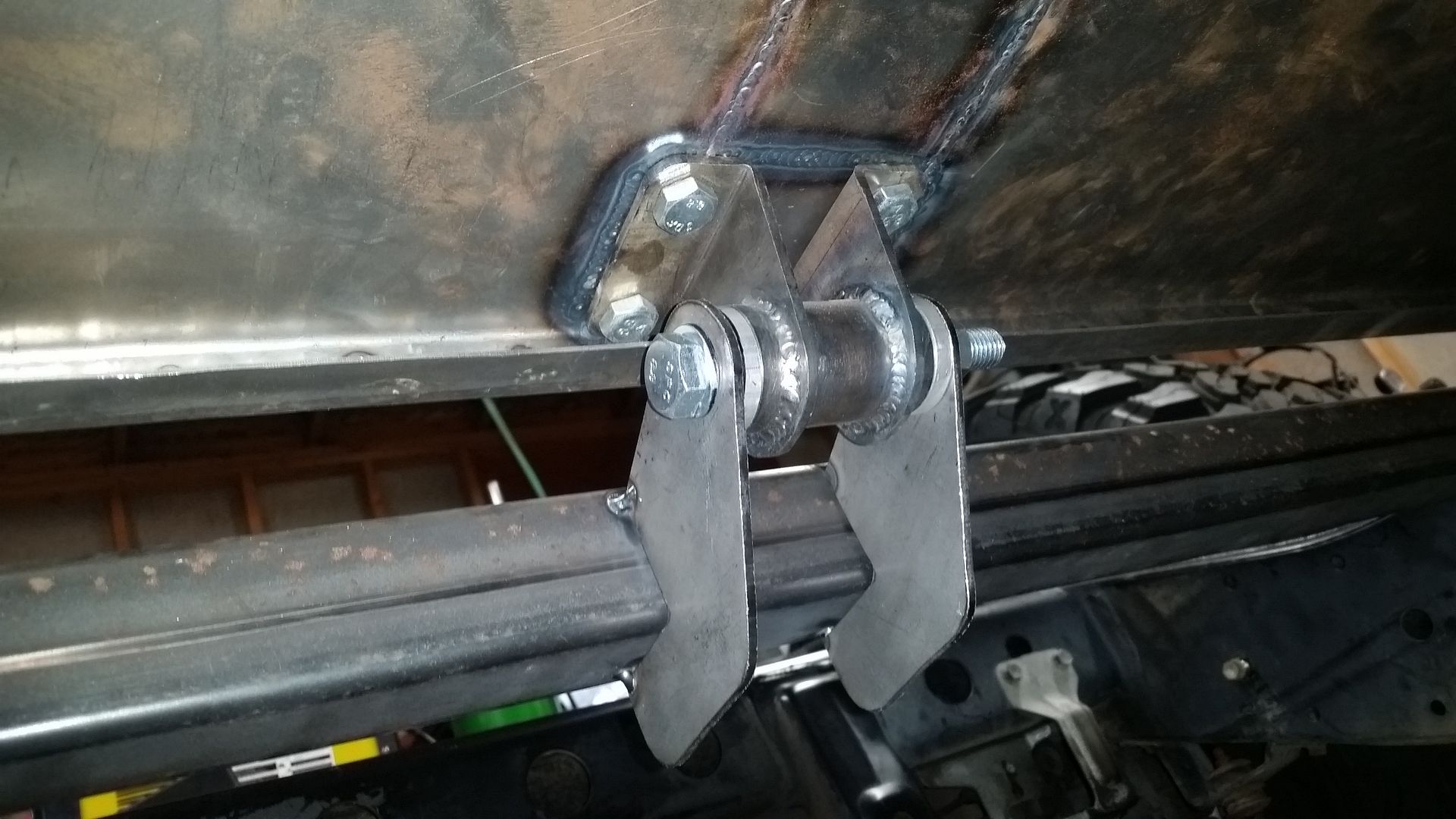

The uprights are 2x2 box that slips over some 1.75 square stock that was welded to the frame. Once everything is in its happy place I will drill and tap the square stock for some 10mm bolts. Basically, pull 4 bolts, a hose clamp, and a wiring plug....then the entire bed will come off.

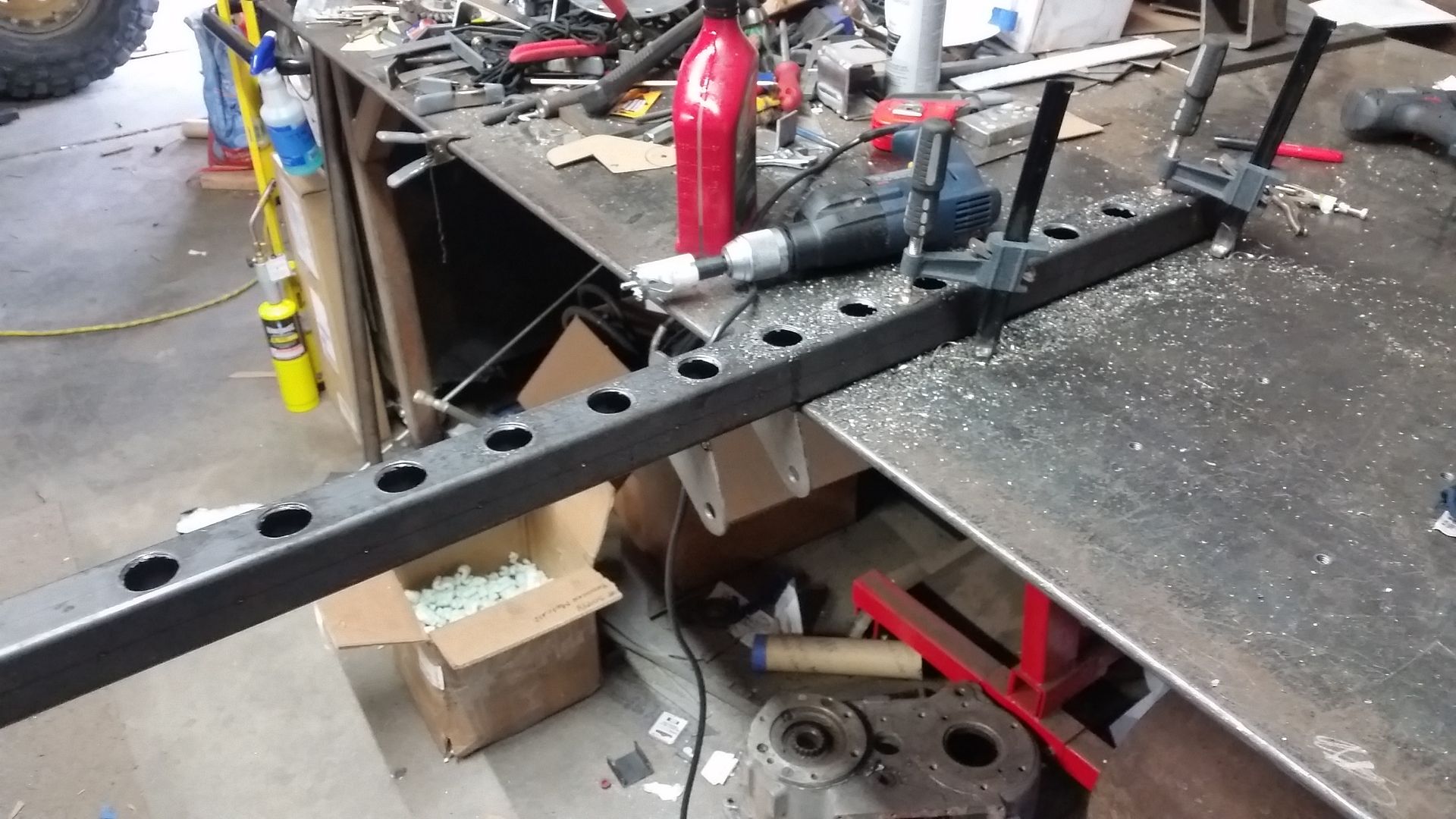

The bed rail ended up being 2" channel with the legs down. This will let me have most of the features I wanted without having to make a complex shape. It was a compromise, but I would like to finish this thing sometime in this decade. I really wanted to be able to have a flat surface I could drill and tap for the bed panel mounting. I also wanted to be able to hook a strap over the edge of the rail.

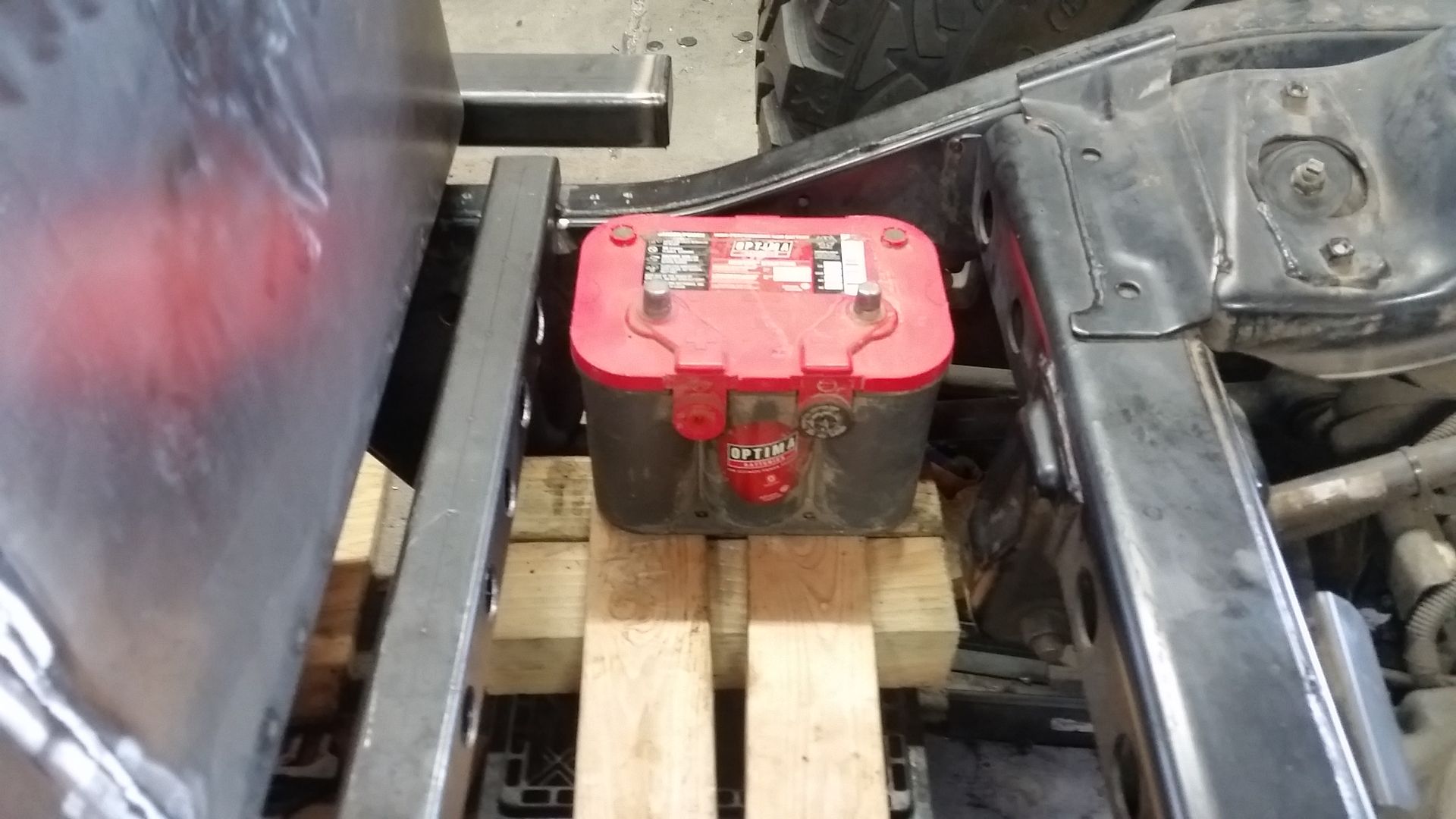

Where it gets a little interesting is the bed floor 'drawer' rail. So one of the big design goals overall was to have a modular hard top of sorts where the panels could be stored 'in' the vehicle. While the rear 'window' panels are going be able to store in the tub behind the seats, the upper part of the doors need a home. I believe the best place for these will be in a false bed floor. I basically want to be able to drop the tailgate and slide out a foam lined drawer to stick the upper half of the doors into.

After going round and round with some possible ideas I decided to keep it simple. I am going to use a section of 3" channel, the lightest I could find ( which is still pretty heavy. The top flange will be used to bolt the bed floor down to, which will probably be some 3/16 or 1/4" aluminum. The lower flange will act like a drawer slide for a large aluminum/wood panel shelf which will slide out onto the tailgate when it is down.

The tailgate will be some aluminum sheet with a flange/hook bent on the top. I think I can use 1/8" aluminum for that. There will be 3 hinges on the bottom to help support the middle since it is about 45" wide total. I plan on using some 90 degree toggle clamps to hold it shut, kinda like the early toyota mini-trucks had.

There will a 5" tall panel under the tailgate that will cover up the tank up to the tailgate seam. The hinges, backup/tail lights, plate light, and a few other little things will attach to that. It is more a spacer, but will stabilize the rear uprights a lot also.

....fun stuff....