Should be quite the runner (see what I did there?:sombrerowhen you are done.

.

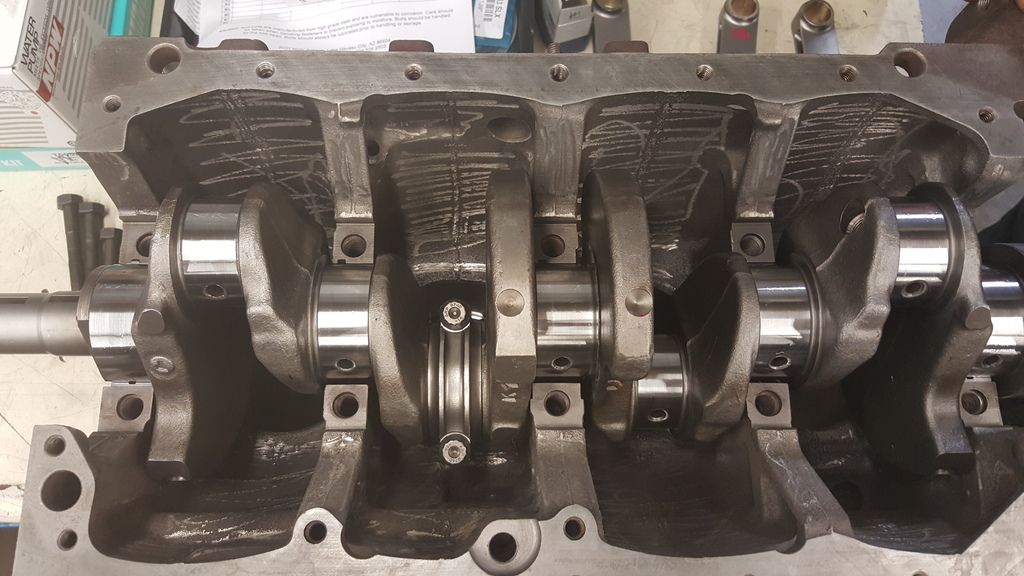

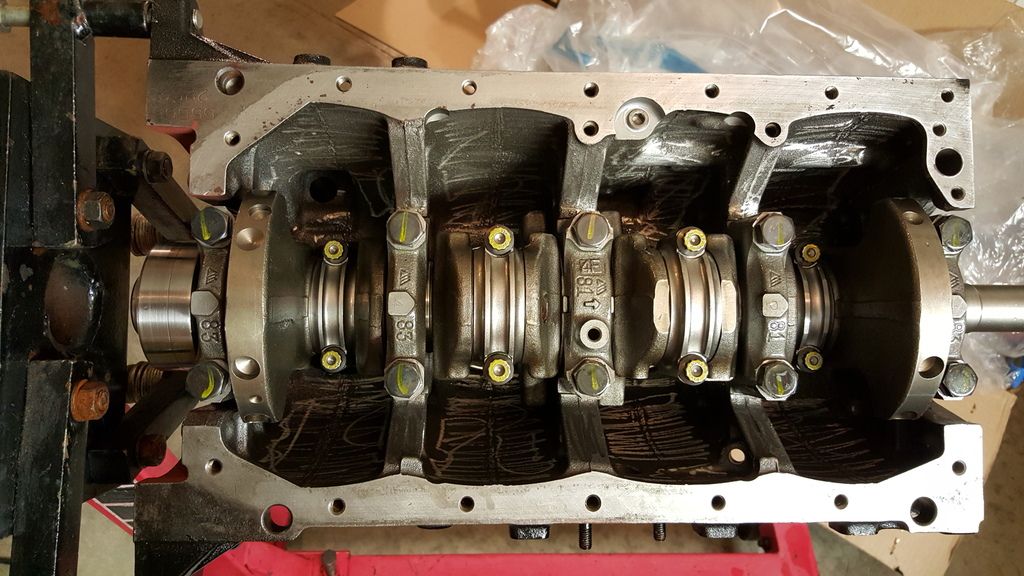

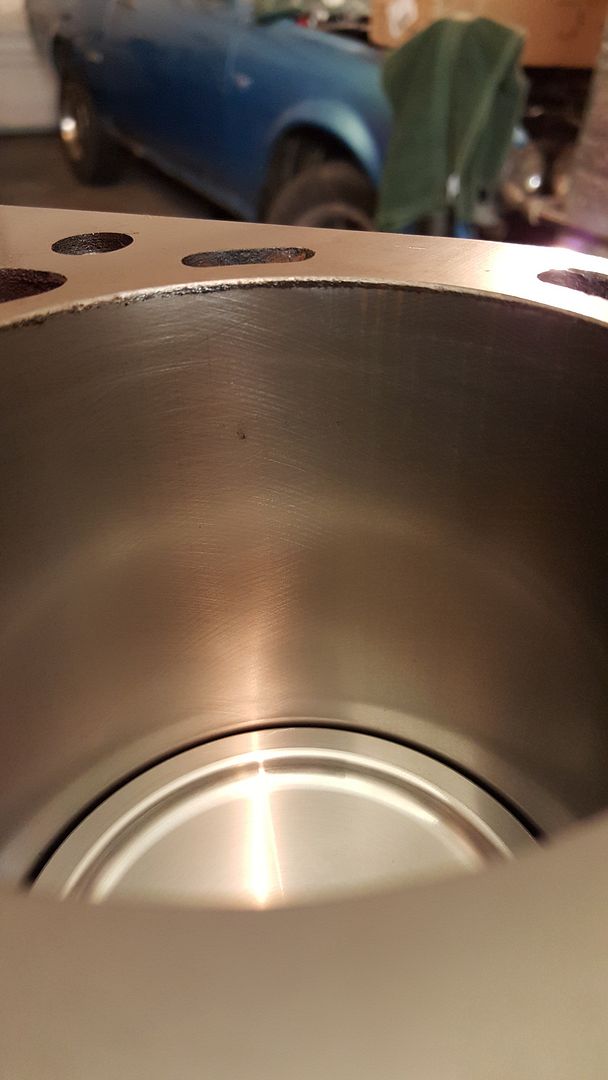

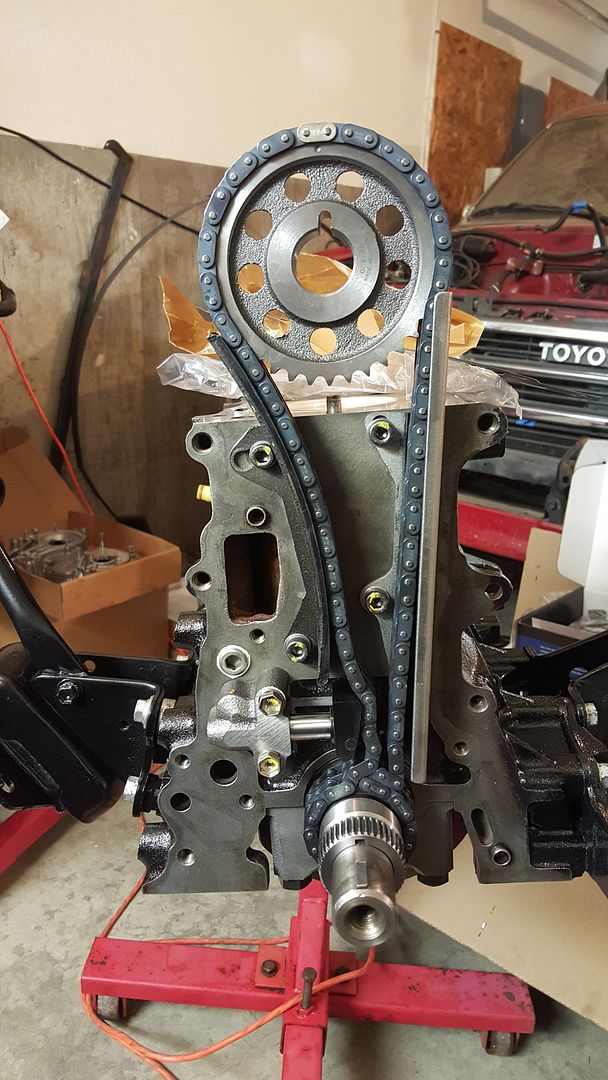

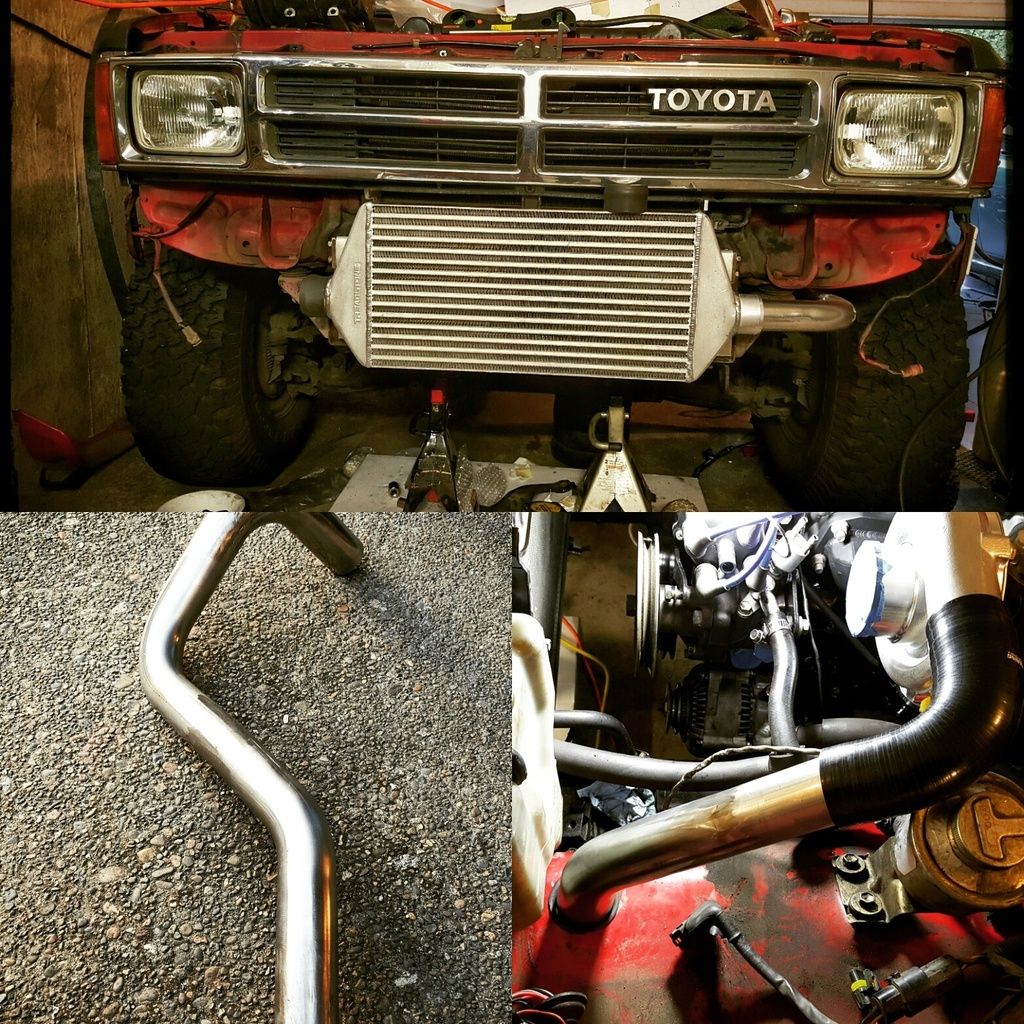

I have an '85 with the 22RTE/R151 swapped in and it had a CT26 on when I got it and it would really sing from 3k on. The oil seals in the turbo were shot, so I ordered a new CT26 and installed it. Was running kind of rough, so I thought I would do a tune up as the plugs weren't looking that great. Ran a bore scope into the cylinders and found:

There was antifreeze in the #2 and #4 cylinders and they were all worn out. In lieu of rebuilding, I am going for a 4.3 swap. Mine was already hacked, so no loss on mine, but I agree with your rebuild on yours, it deserves it.

.

Jack

Ah man, just when you got a new snail on there too. Do you have a link to your build thread? I'd like to read it.