SO just hand laid layers of glass and epoxy over a set of moulds or plugs? I thought about mocking up a design using coroplast and then fiberglassing layers over it since it won't stick to it. You probably don't want to talk too much about how you made it because it's your business; it makes perfect sense. Will visit your site and see what what you have to offer. Nice work

I don't have a web site and I'm not in business, I'm just a guy who wanted a fiberglass military trailer so I designed and built one. After I finished it, a company contacted me and licensed the design from me and they sell it. I don't sell anything.

I think many of your questions will be answered in the first 10 pages of this thread, but I'll summarize here.

I started by making mold masters out of wood. There are only two parts for this tub, the sides and the ends, so I only made two masters. Both are shown in this photo before I put a nice finish on them:

The master for the side panel with a final finish on it:

Once those were complete, I made molds on them.

Once the molds were cured I popped them off the masters:

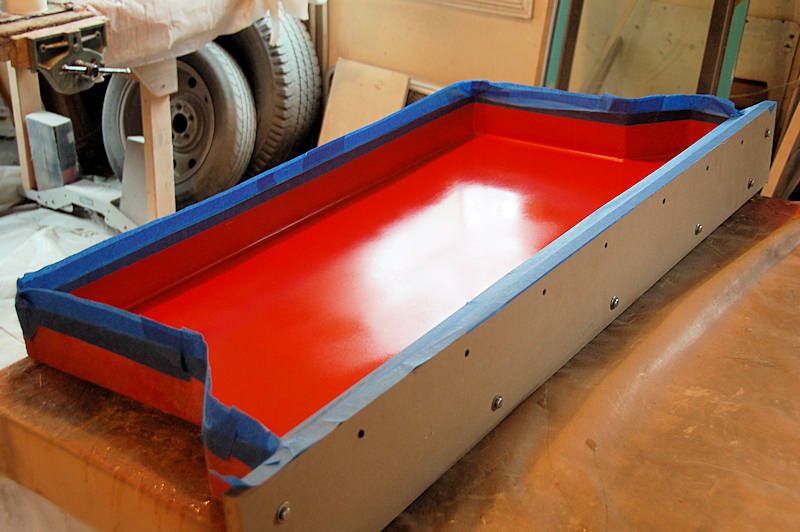

The molds were then prepped with mold release:

Then I shot the inside of the molds with gelcoat and laid up fiberglass over the gelcoat. The first two parts out of the mold, they're slightly green because the mold release hasn't been washed off yet.

The first set of parts clamped together:

BTW the tailgate end panel was made in the same mold as the solid end panel, an insert was placed in the mold to form the tailgate opening.

The process for making the fiberglass lid is also in the thread.

I hope this helps. I'm happy to answer any other questions you might have. All of the photos above were posted in the first 10 pages of this thread, there's more info there.