Buffalobwana

Observer

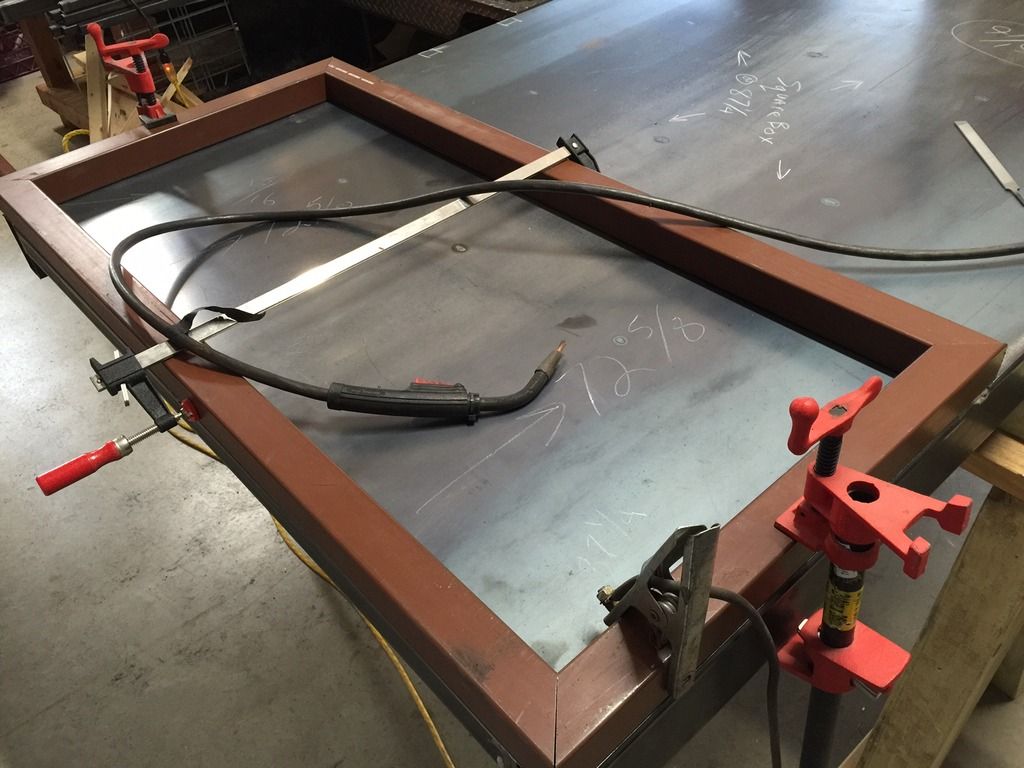

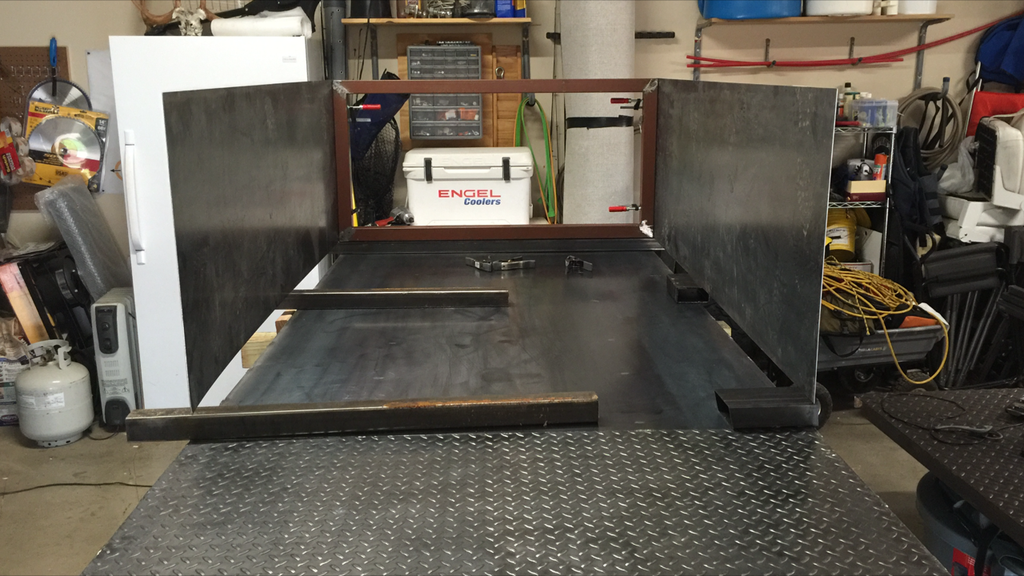

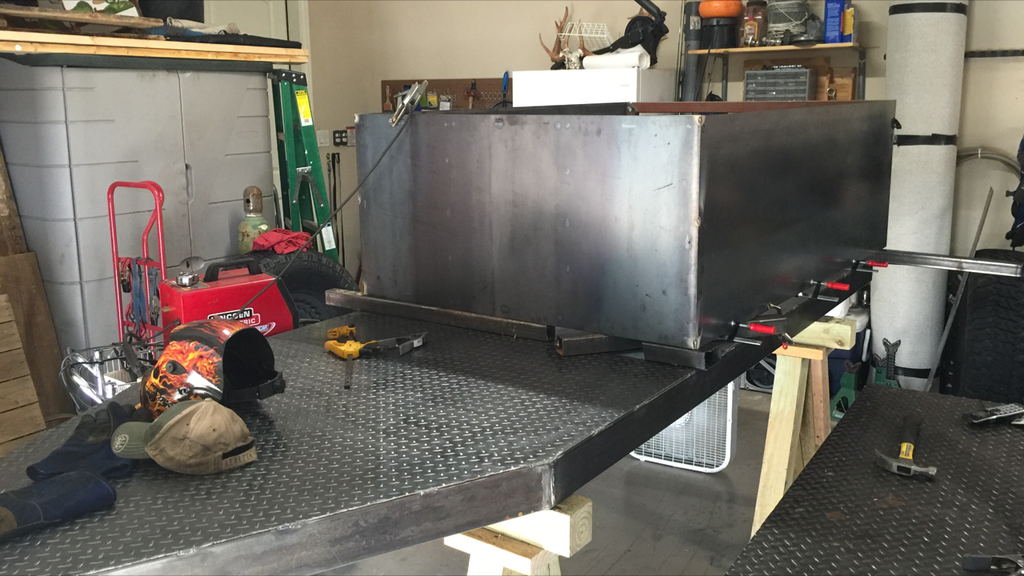

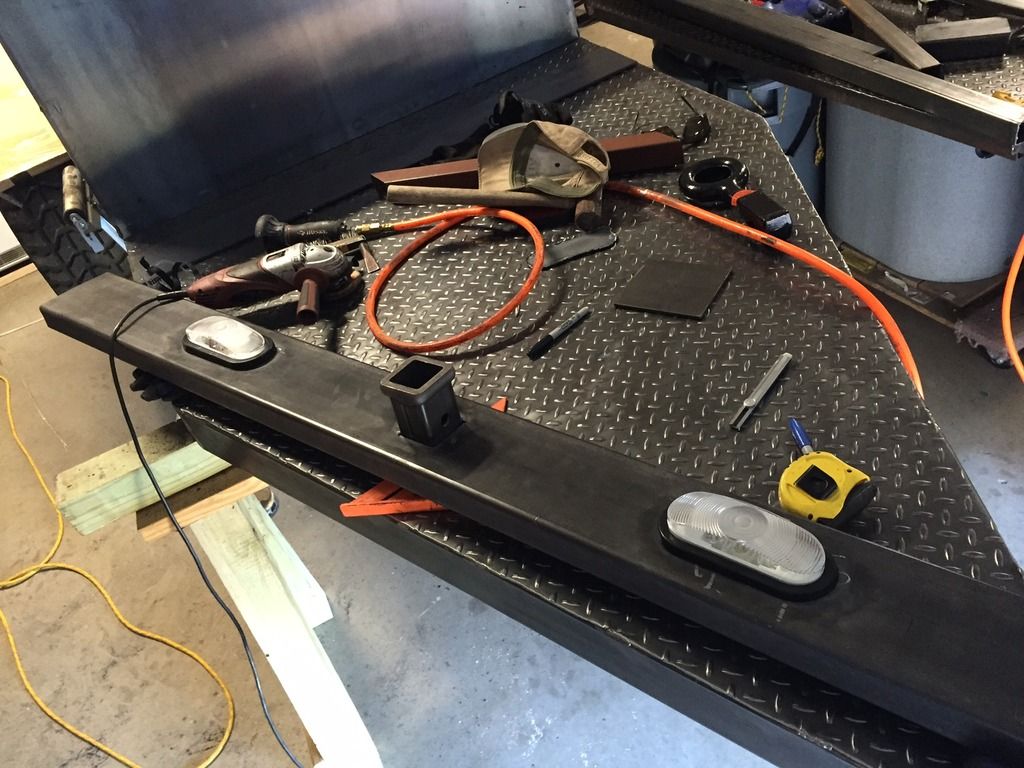

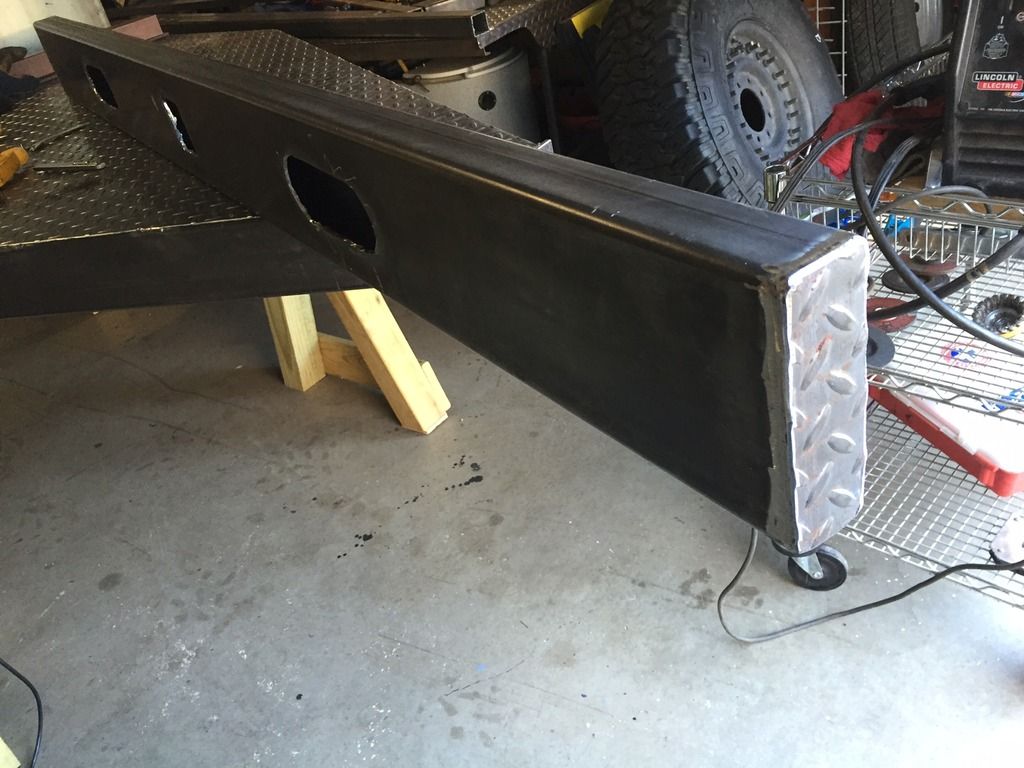

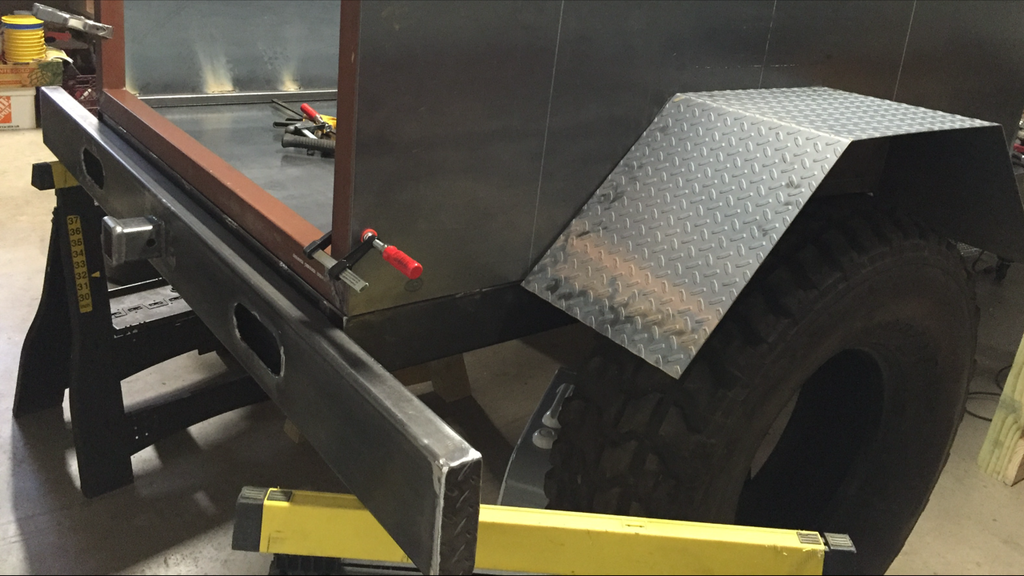

Ok, finally got some time to start the project. After a lot of measuring, tweaking, twerking, and adjusting, the metal started flying. Here is the end of day 1 with nothing welded, but all my 12.5 deg and 25 deg pieces cut and ready to weld.

I planned for a 50 degree tongue, and will mount a flat plate to it. Now, I may cut a hole in it and run an 18" receiver tube to a crossbar. That is how I have it planned, but welding a channel to it and bolting a lunette ring may be how I go. I can do either with this plan, so I will sleep on it.

Will weld this plate on the front.

This new saw that I got is impressive. With a 50 deg tongue, I need accurate 12.5 and 25 deg cuts. This saw is spitting them out with amazing accuracy.

Quite impressed with this machine.

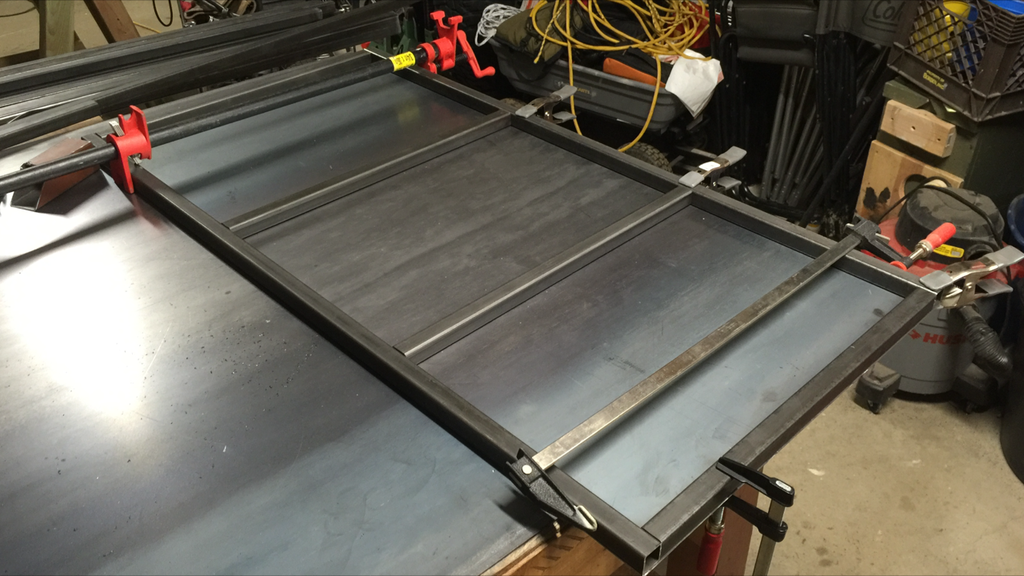

Will start squaring it up and tacking everything together next. If all is coming along, will put 2x2x11ga cross beams for the floor in once the frame is tacked together.

I planned for a 50 degree tongue, and will mount a flat plate to it. Now, I may cut a hole in it and run an 18" receiver tube to a crossbar. That is how I have it planned, but welding a channel to it and bolting a lunette ring may be how I go. I can do either with this plan, so I will sleep on it.

Will weld this plate on the front.

This new saw that I got is impressive. With a 50 deg tongue, I need accurate 12.5 and 25 deg cuts. This saw is spitting them out with amazing accuracy.

Quite impressed with this machine.

Will start squaring it up and tacking everything together next. If all is coming along, will put 2x2x11ga cross beams for the floor in once the frame is tacked together.