Kmrtnsn

Explorer

man, I'd really like to be able to purchase one of those with the table??

You and me both.

man, I'd really like to be able to purchase one of those with the table??

This would be a great option for Ursa Minor to offer for the J30 poptop camper for the JKs. I would think that the glass lift gate is a hassle with the poptop open and it would negate the need to buy the rear glass hatch when the starting JK is a soft top....

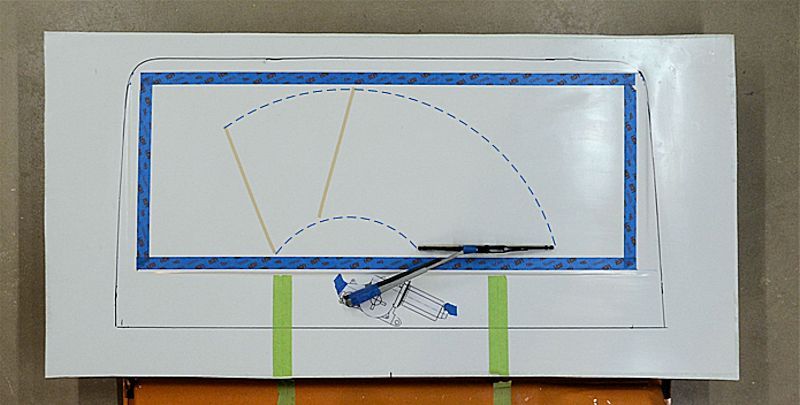

I am not convinced a rear wiper is necessary though.

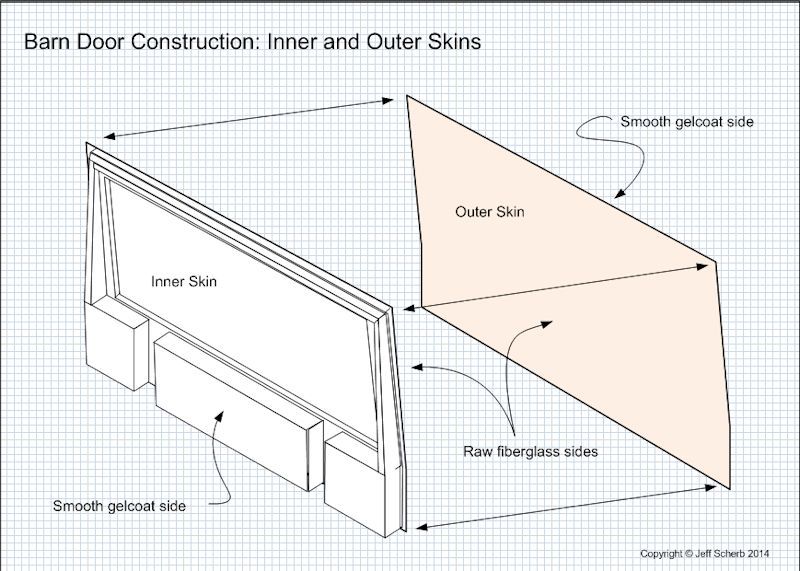

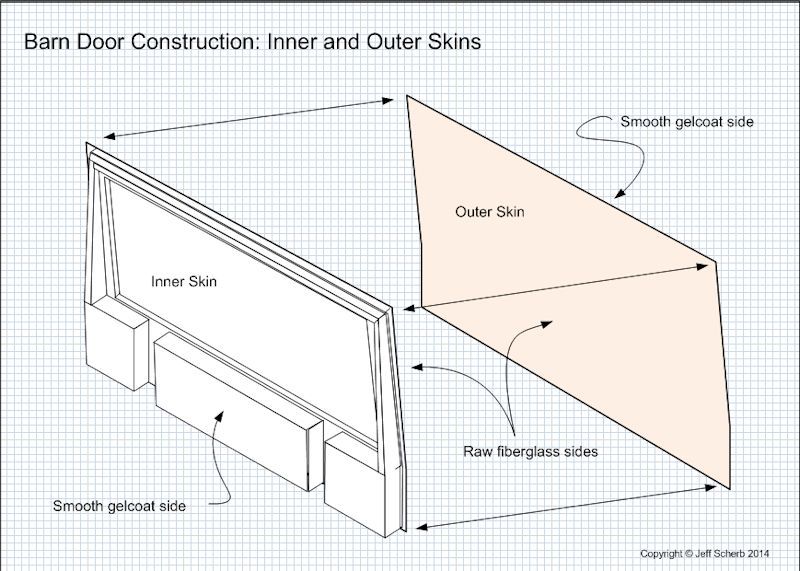

I love that barn door idea!! Just found a pic of a ballistic test of a igms J8 Jeep outfitted with" twin barn doors"... nice idea as well, no?

Something that could be neat is if the rear window could pop open at the bottom by a few inches. Like those old van windows in the back to help let air flow through better. Or just being able to open the window with the door closed.

Not to highjack any further, but speaking of Freedom panels I called the dealership the otherday and they wanted $750 Canadian for each side! And 2800 bucks for the whole top! And that's just for a 2 door! I was thinking it would be neat to run the panels as a hardtop bikini but not at that price!