I bet we could easily get a Group Buy together with any of the custom off road trailer builders to build a simple, straight forward chassis for this project. Unlike the HF, it could be heavy duty, off road worthy trailer that could take 35" tires. I bet it wouldn't cost more than a few hundred dollars more than the HF. I know I'm in, how about you?

Kerry

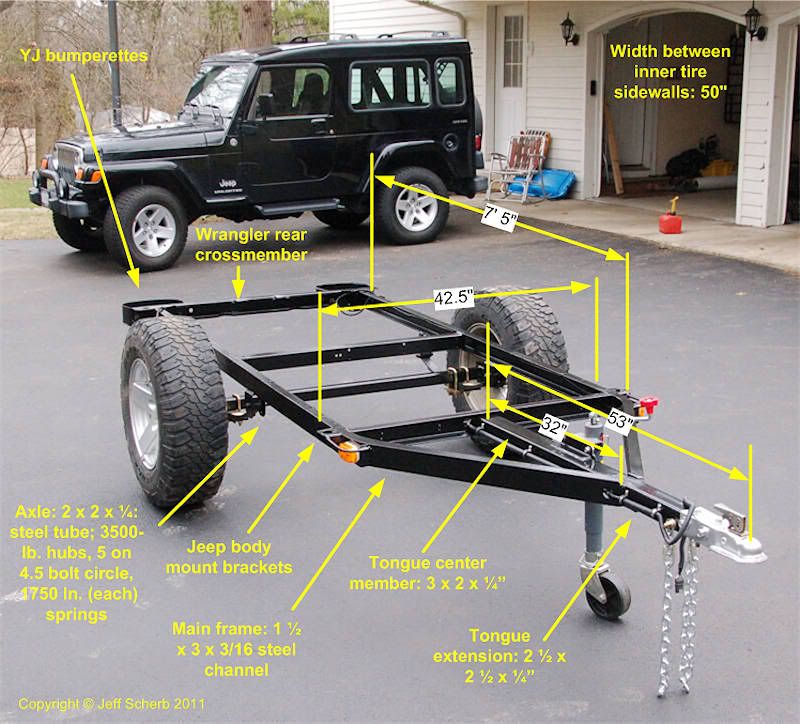

If you've got a welder, here's a strategy for building a trailer frame that would be good for off-road use...

In post 25 of this thread I showed how I plan to modify heavy duty HF trailer frame down to 4x4 for use under my proof-of-concept trailer, which I would recommend for nothing more challenging than an improved trail. The steel in the frame is of a gauge sufficient for off-road use, but the bolt-together construction wouldn't be a good idea off-road. Also, the axle and springs are a little light weight to handle large tires off road.

Here's what could be done to turn that into an off-road capable frame:

1. Assemble the HF heavy duty trailer frame as shown in post 25 including the extra crossmembers and extra tongue member, but weld all the joints together. Do not install the axle or springs. $320 on sale plus discount coupon.

2. Get a 3500-lb. capacity axle of the proper track width. $100 from a source like KMT Service Parts.

http://kmtparts.com/axles-spring-mo...000lb-torflex-axle-eb-ez-lube-655-4-drop.html. Or, since you've got a welder, buy a pair of hubs from Tractor Supply or Northern Tool and some steel for an axle tube and weld up your own (although that may end up costing more than the KMT axle).

3. Get some 1750-lb. (each) capacity springs, plus spring hangers/shackles from either Harbor Freight or Northern Tool. Weld the spring hardware to the frame and bolt up the axle. ($80).

4. So far, the total is $500 (a little less than a $200 upgrade from the base HF trailer). Sell the 5.30x12 wheels/tires from the HF kit on Craigslist, hope for maybe $50, so now we're at $450. You might be able to sell the HF axle/springs as well.

5. Bolt up your favorite wheels and tires. You might also consider a coupler with more articulation, depending on the type of terrain you plan to tow through.

I suppose you might be able to build a frame from scratch for the same price or maybe less, but doing it this way is pretty quick and easy - all the metal is cut, and the kit comes with lighting and a coupler, just weld the parts together.

Here's the photo from post 25 showing the modifications I'm planning to make; see that post for a description.

Disclaimer: any applicable taxes and shipping isn't included in the numbers above.