The beautiful 80 degree late September weather coaxed me to the driveway this afternoon. On the docket: Fuel Tanks

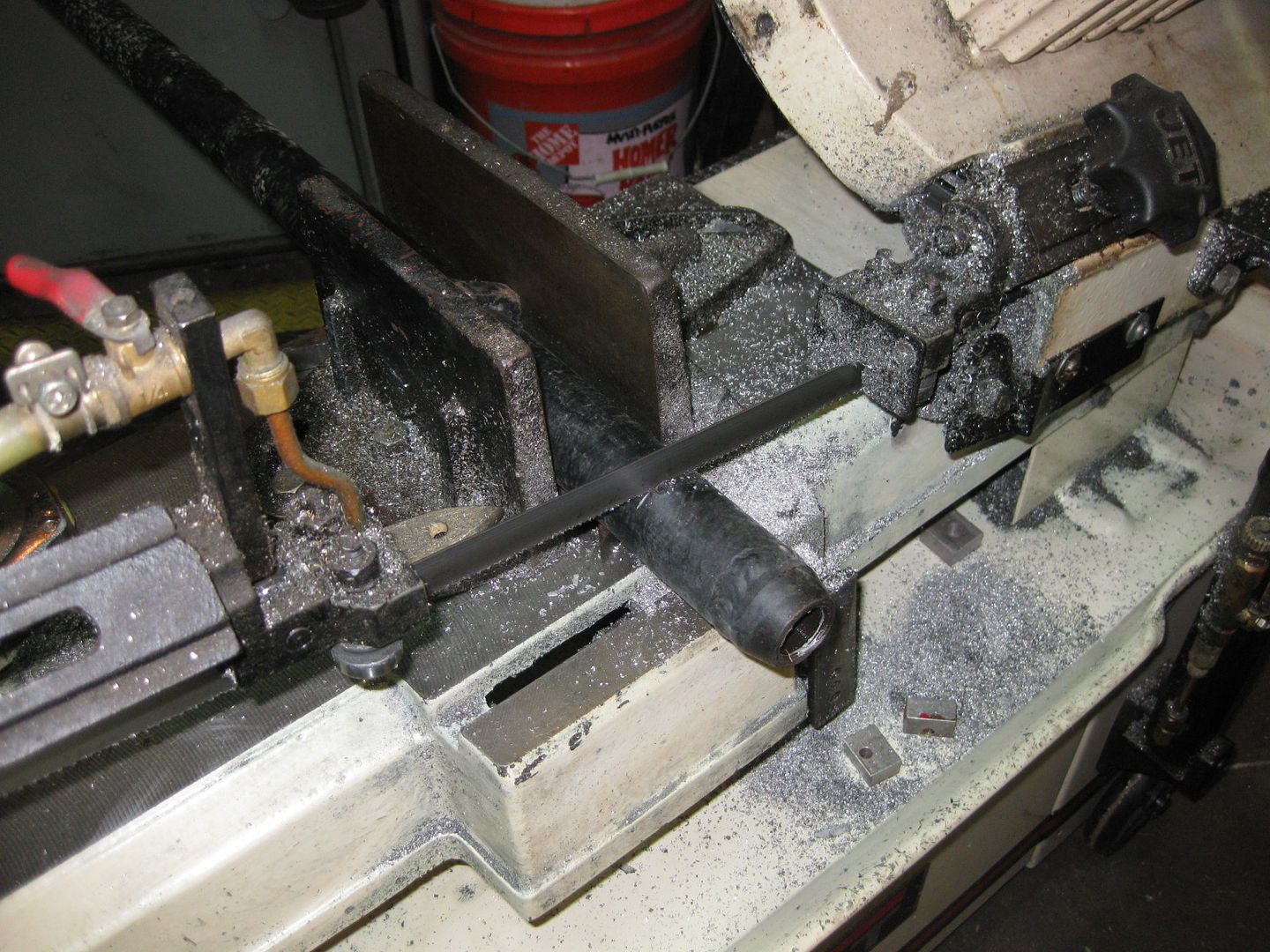

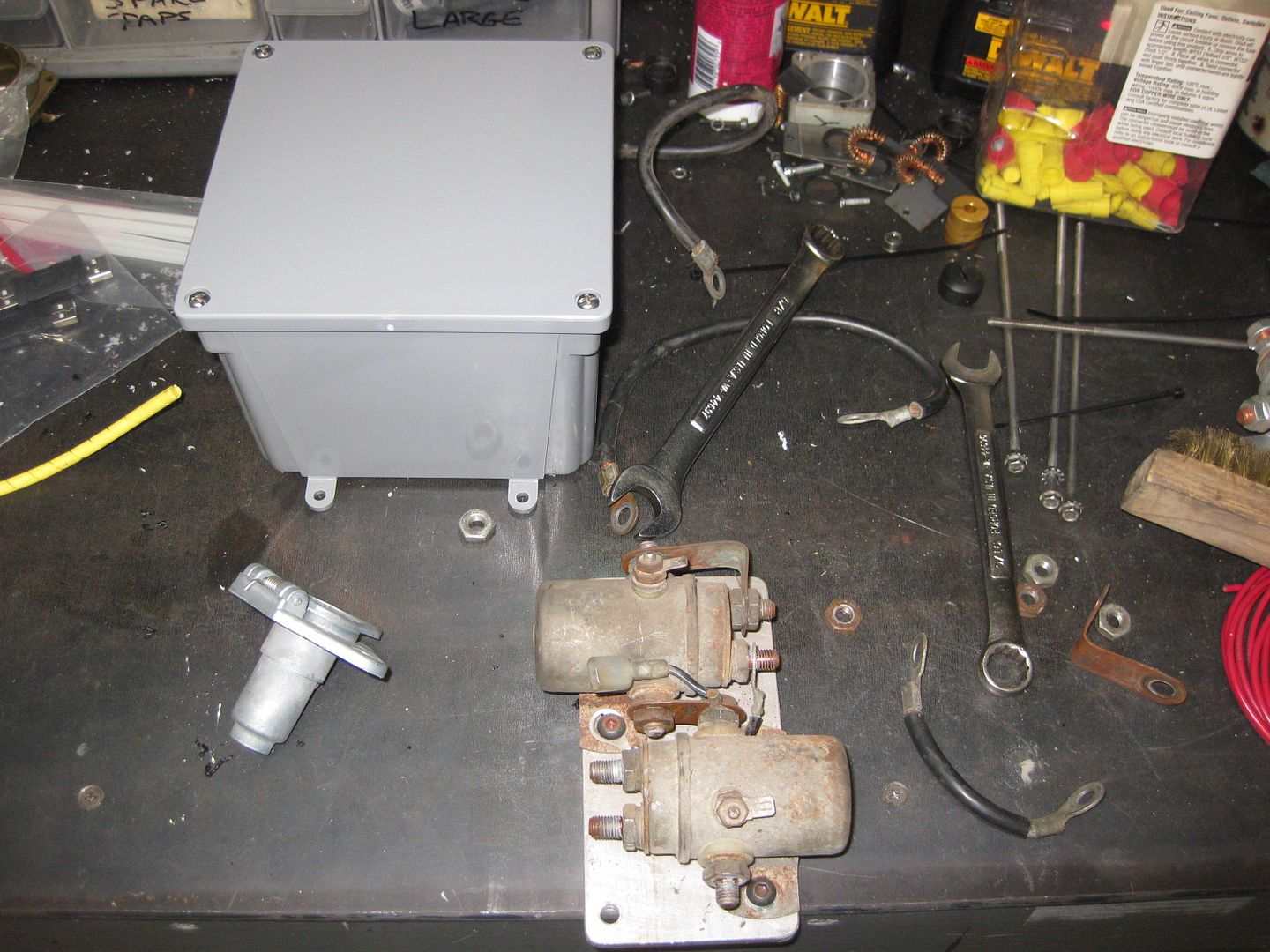

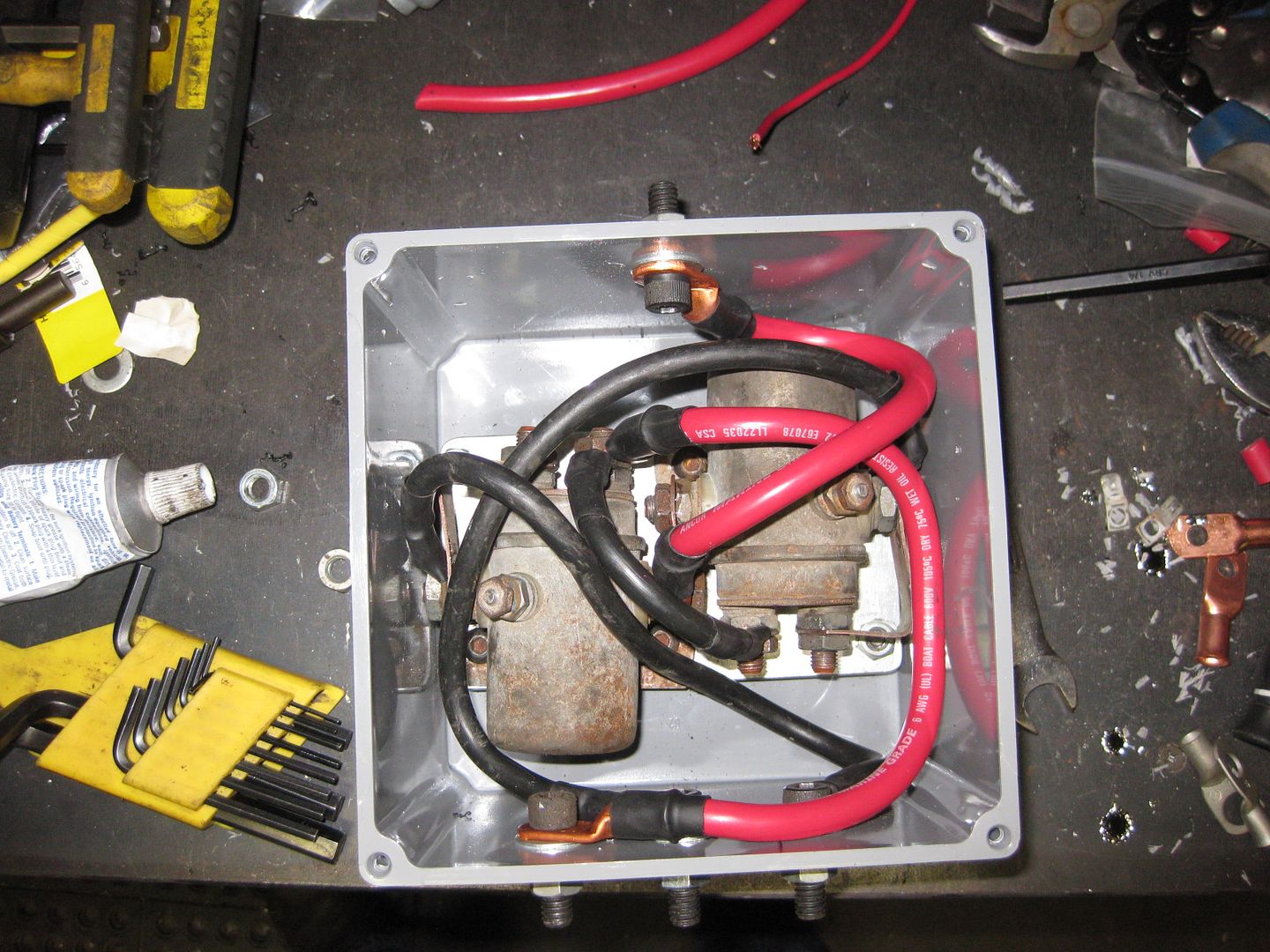

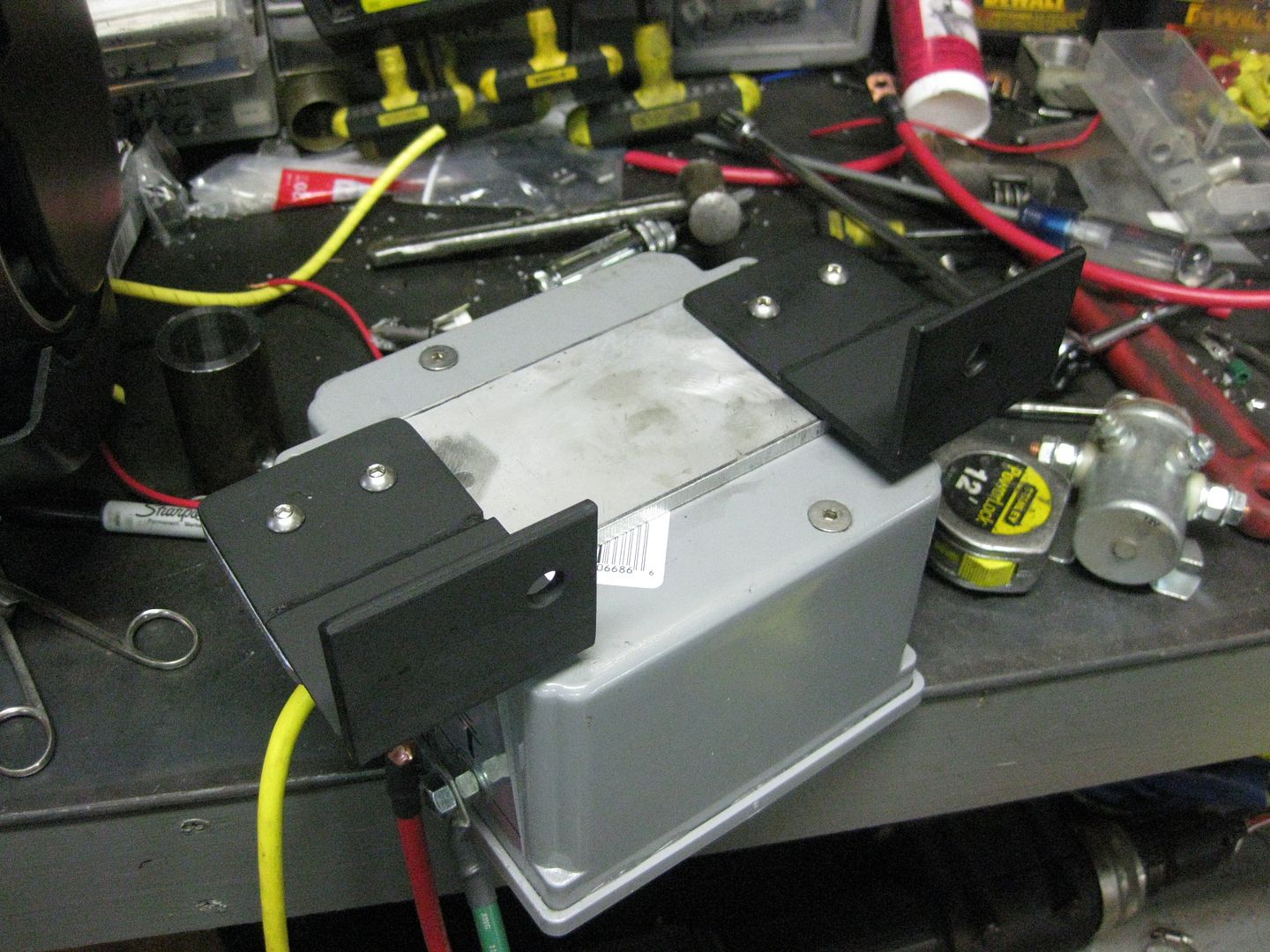

I have never been able to draw a full 18 gallons from the front tank and the front sender recently stopped working entirely. The rear sender has been quirky since we first bought Boomer, so both tanks needed to be dropped to investigate the problems. The first step was to drain as much of the fuel from the front tank as possible. I opted to throw together a fuel transfer pump to ease the process. There was an old 12V gear pump on the shelf which worked perfectly. I tapped into the system before the water/fuel separator and brought the tank down to where the pump was sucking air.

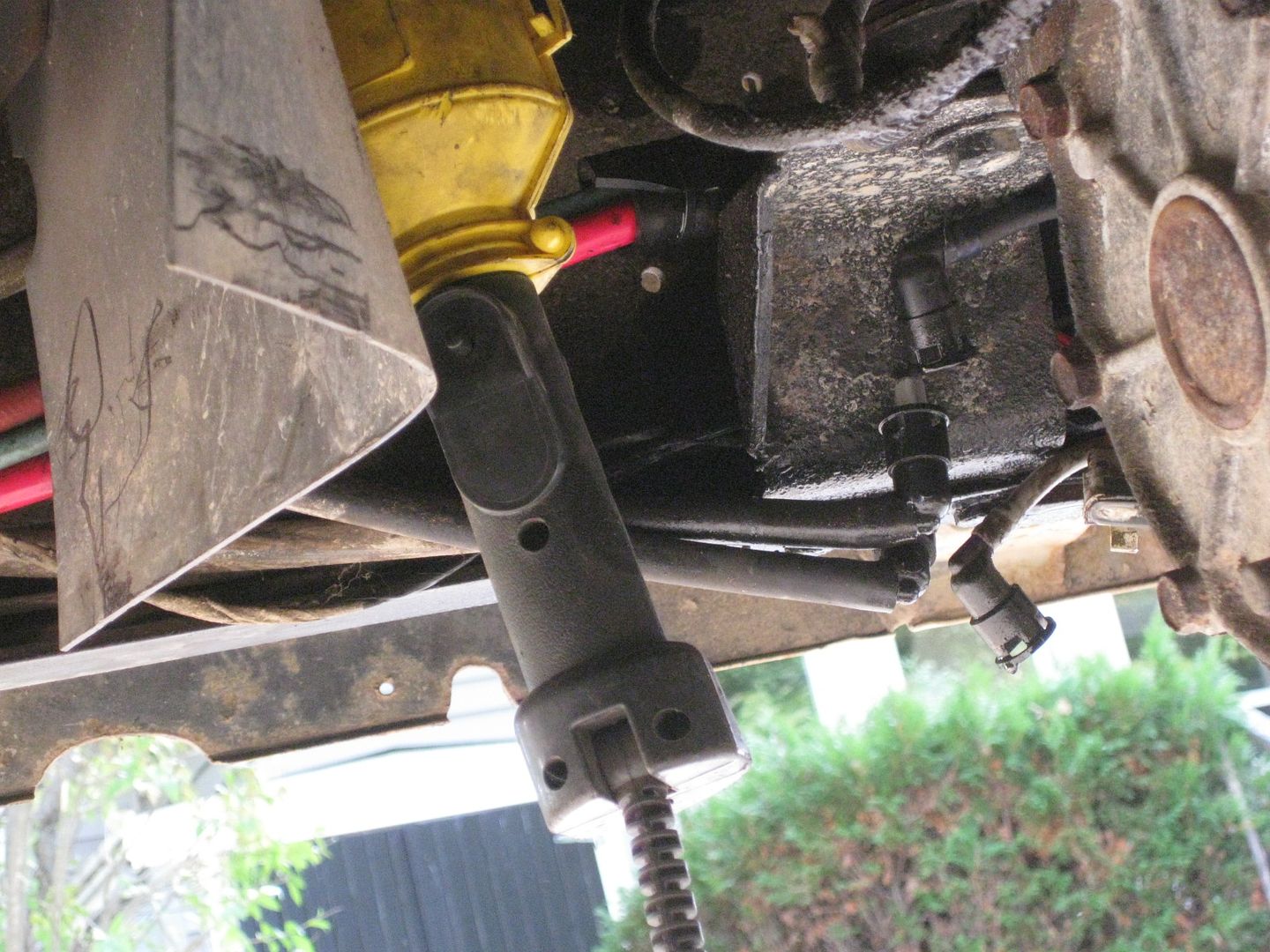

I have been coating the hanger bolts with PB Blaster for the last week, and everything came apart without much issue.

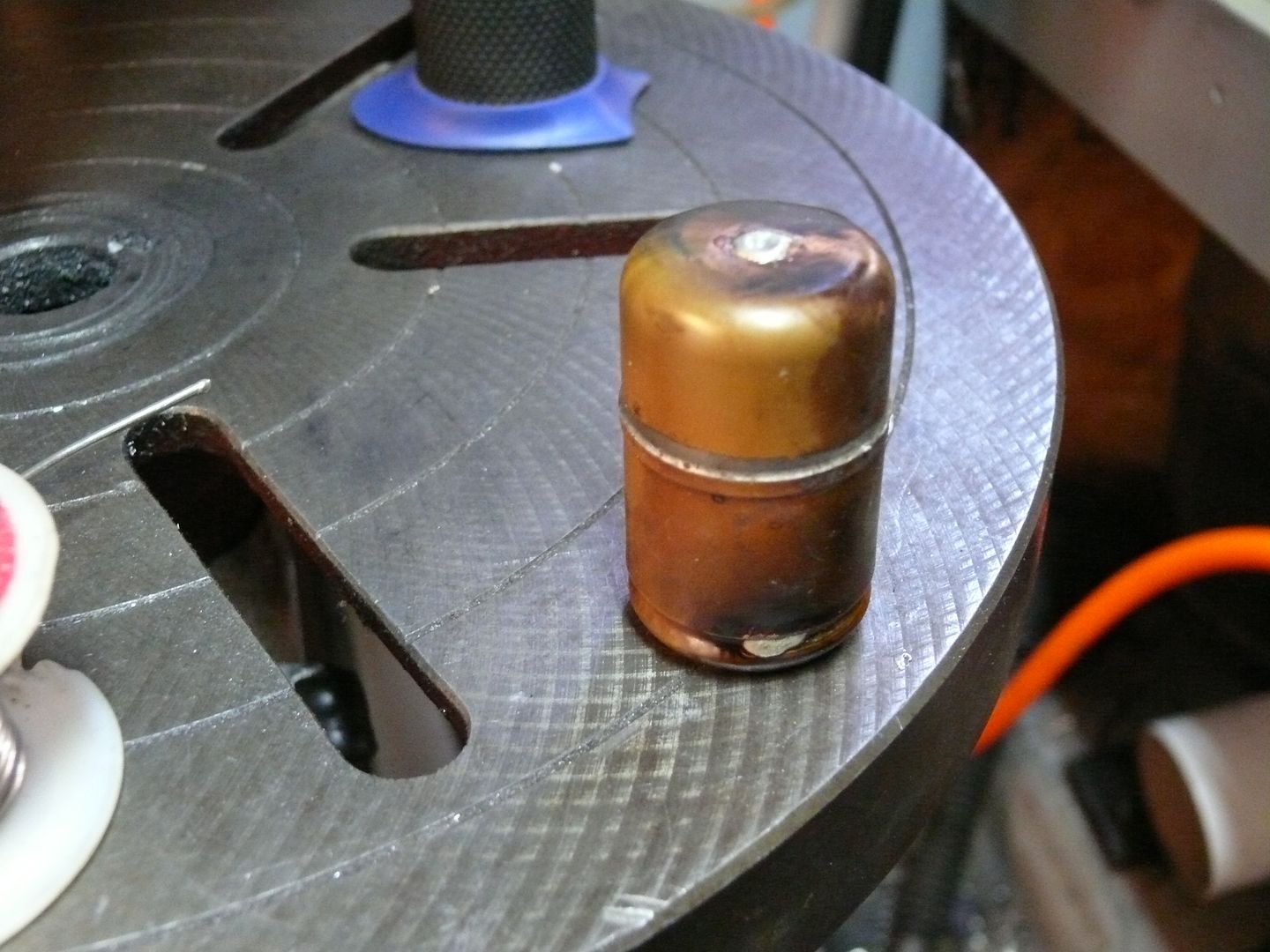

The sending unit came out easily and it was immediately clear why the tank couldn't be fully consumed. The pickup tube had fallen off.

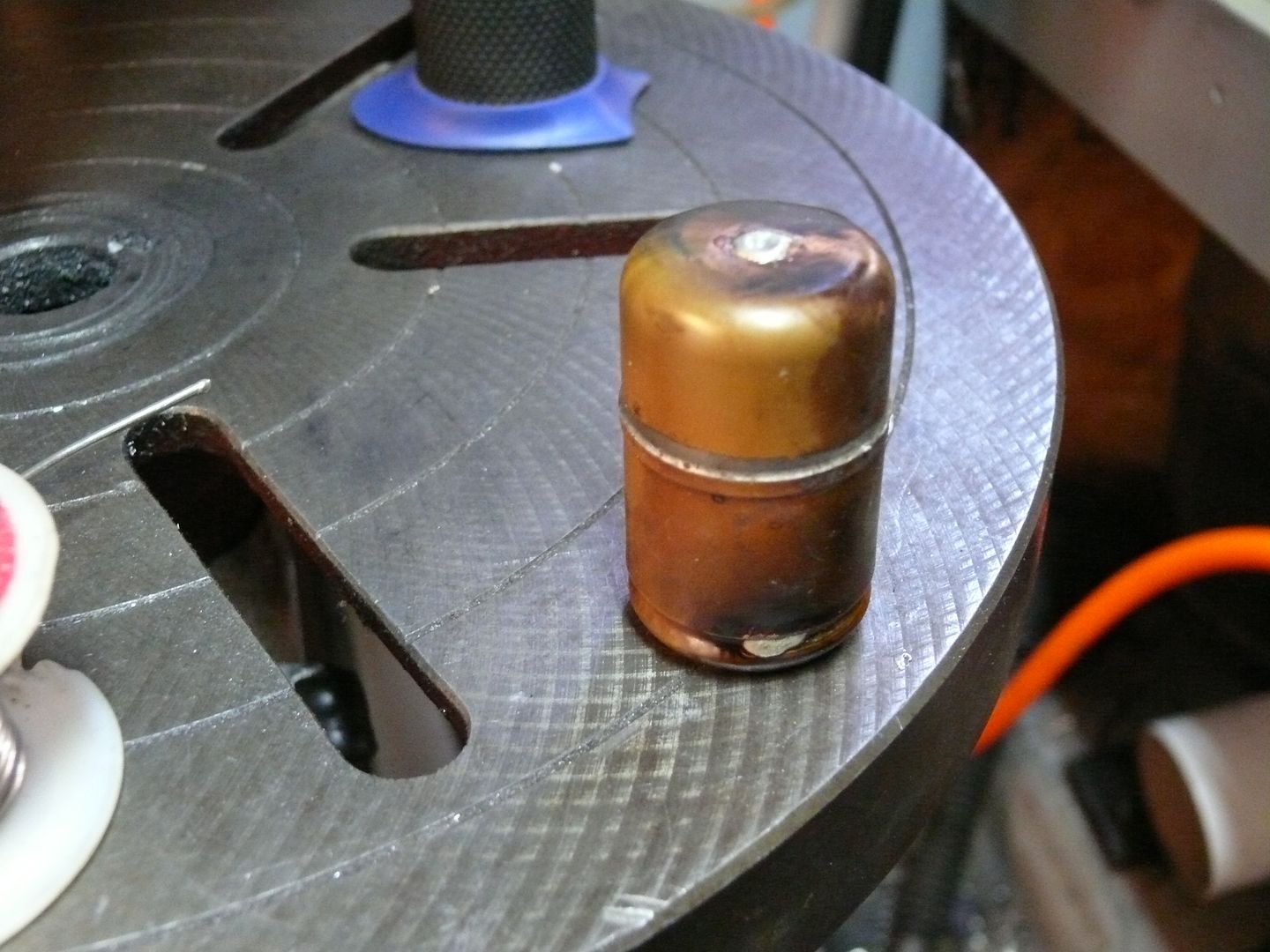

When I started to tear into the sender a bit further I found a float full of fuel and a worn out rheostat in the float level sensor.

I tried to re-position the wiper but it broke. Of course. A little soldering and it was back together, and I was able to position the wiper along a new track. For whatever reason this sending unit isn't available online in any of my usual haunts. They are all for the gasoline variants which include a fuel pump bracket and an incorrect wire connection plug. I would rather have just installed a new sending unit assembly, but this isn't a possibility at the current time. To address the float full of fuel, I drilled a couple holes in it to drain, then identified a couple extra leak points with some pressurized air, and soldered everything back up.

I ran the multimeter across the sending unit and got some relatively decent feedback (90 ohms to 20 ohms).

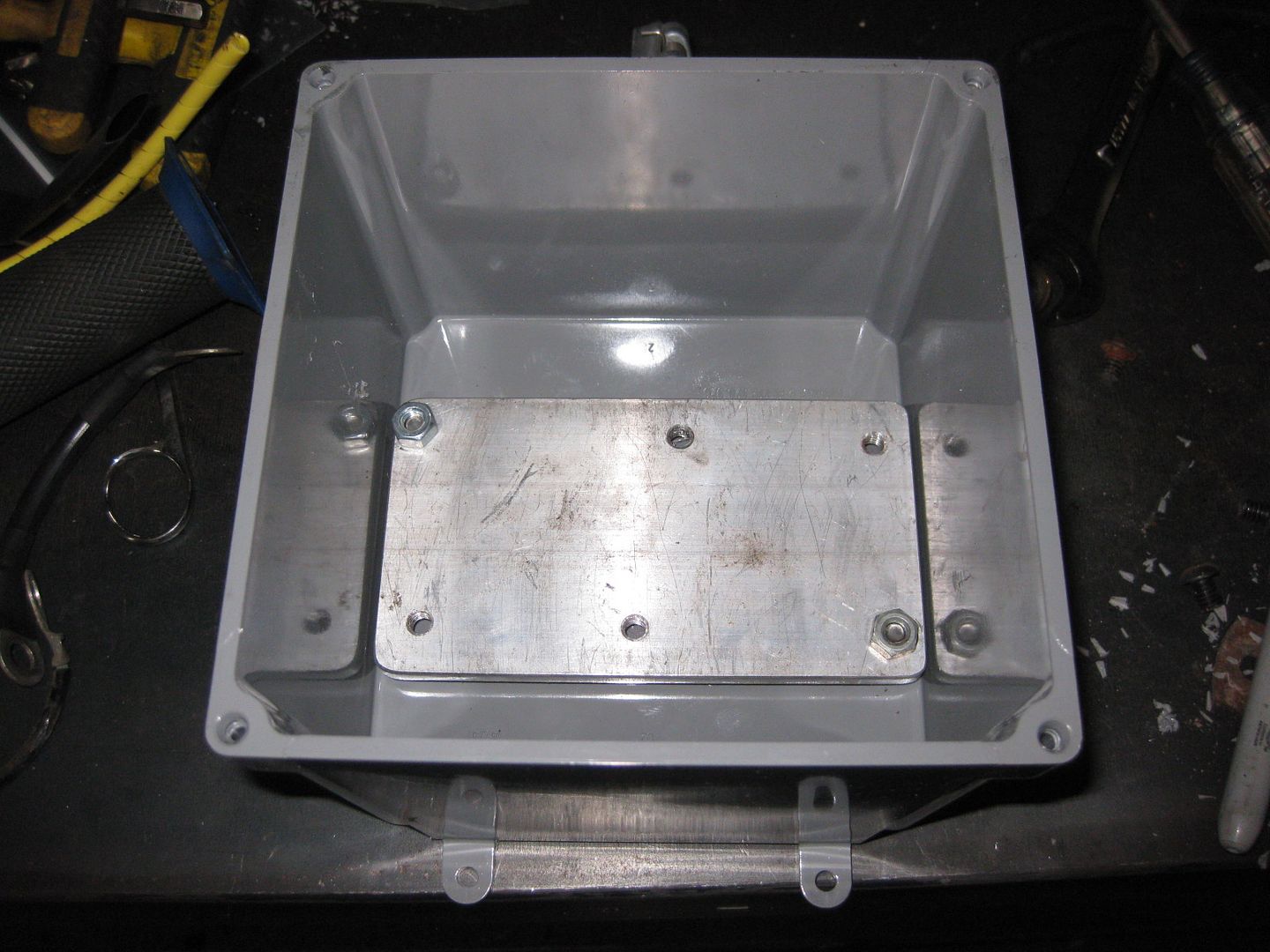

Reassembly time.

There was still maybe 2" of fuel in the tank (~3 gallons), so I re-configured the pump system to suck directly from the tank. With the new pickup in place, I was able to get everything out which eased the re-installation considerably.

After that was buttoned up it was time to transfer 15 gallons from the rear tank. This process was slow as I first would fill the 5 gallon jug with the transfer pump, then dump the jug into the front tank, then back to fill the jug with the transfer pump. Eventually it was emptied and the tank came out without issue just like the front tank.

The pickup in the rear tank was fine but I removed it and installed the same hose type pickup as I did for the front tank. The rheostat for the rear sender was equally trashed, but I was able to re-bend the wiper (without breaking it) and got a consistent reading across the whole sweep.

The tank went back in easily. The front sender still doesn't seem to be behaving so I may have to figure out how to retrofit some other potentiometer element at some point. For now, I at least know I've got 18 gallons of usable capacity in the front, and 22 gallons of usable capacity in the rear. Things are looking up.

SG