superbuickguy

Explorer

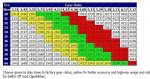

4.10

I have a H3 Hummer Alpha. That is a H3 with the 5.3 motor and 4L60e transmission. Fully loaded I'm tipping the scales at 6000 lbs. I have 315/75 16 tires. I've done a 1.5" torsion bar lift (all that's needed to clear 35s with an H3)

4.10 is a good compromise between decent pulling power and the inevitable fuel economy you're going to lose.

Something to consider - your front differential - they are not terribly robust, thus you may need to do a full consideration about what you really want the rig to do before you spend money that you'll lose when you make the next upgrade. For example, since you have a half-ton, you can swap in a light-duty 3/4 ton pumpkin in the front, then either replace the rear with a non-float 14 bolt (6 lug) or go whole hog with a solid axle swap front (SAS) dana 44 or dana 60 and a full float 14 bolt rear.

It all depends on your ultimate goal and how much you're willing to spend... a plan helps so you don't spend twice (especially since 3/4 front differentials tend to come in my more off-road friendly gear ratios). You honestly cannot get a better starting-point for a platform then a LS motor and 4L60e transmission.... axles and everything else is pretty easy to swap when compared to making electronics speak nicely to each other..

I have a H3 Hummer Alpha. That is a H3 with the 5.3 motor and 4L60e transmission. Fully loaded I'm tipping the scales at 6000 lbs. I have 315/75 16 tires. I've done a 1.5" torsion bar lift (all that's needed to clear 35s with an H3)

4.10 is a good compromise between decent pulling power and the inevitable fuel economy you're going to lose.

Something to consider - your front differential - they are not terribly robust, thus you may need to do a full consideration about what you really want the rig to do before you spend money that you'll lose when you make the next upgrade. For example, since you have a half-ton, you can swap in a light-duty 3/4 ton pumpkin in the front, then either replace the rear with a non-float 14 bolt (6 lug) or go whole hog with a solid axle swap front (SAS) dana 44 or dana 60 and a full float 14 bolt rear.

It all depends on your ultimate goal and how much you're willing to spend... a plan helps so you don't spend twice (especially since 3/4 front differentials tend to come in my more off-road friendly gear ratios). You honestly cannot get a better starting-point for a platform then a LS motor and 4L60e transmission.... axles and everything else is pretty easy to swap when compared to making electronics speak nicely to each other..