My girlfriend works at Lowe's and this week was employee appreciation week so we get 20% off instead of the usual 10%. There were some extra discounts on top of that for certain items too, like our new Nest E thermostat. Sooooo, I bought all the supplies for my flooring project.

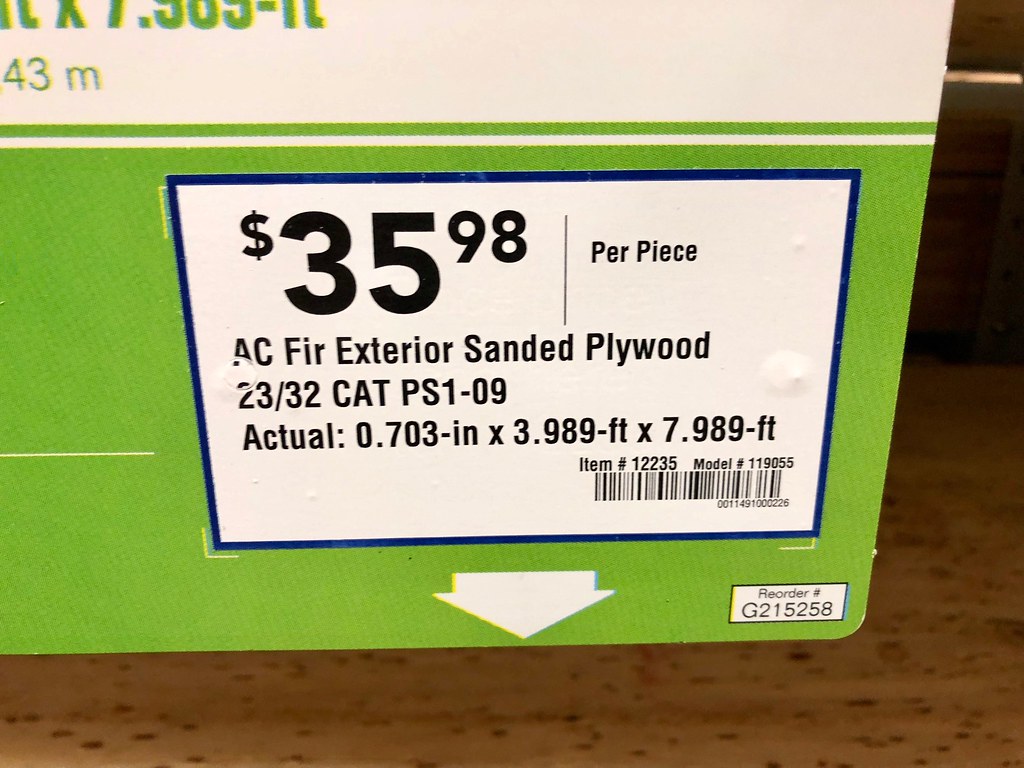

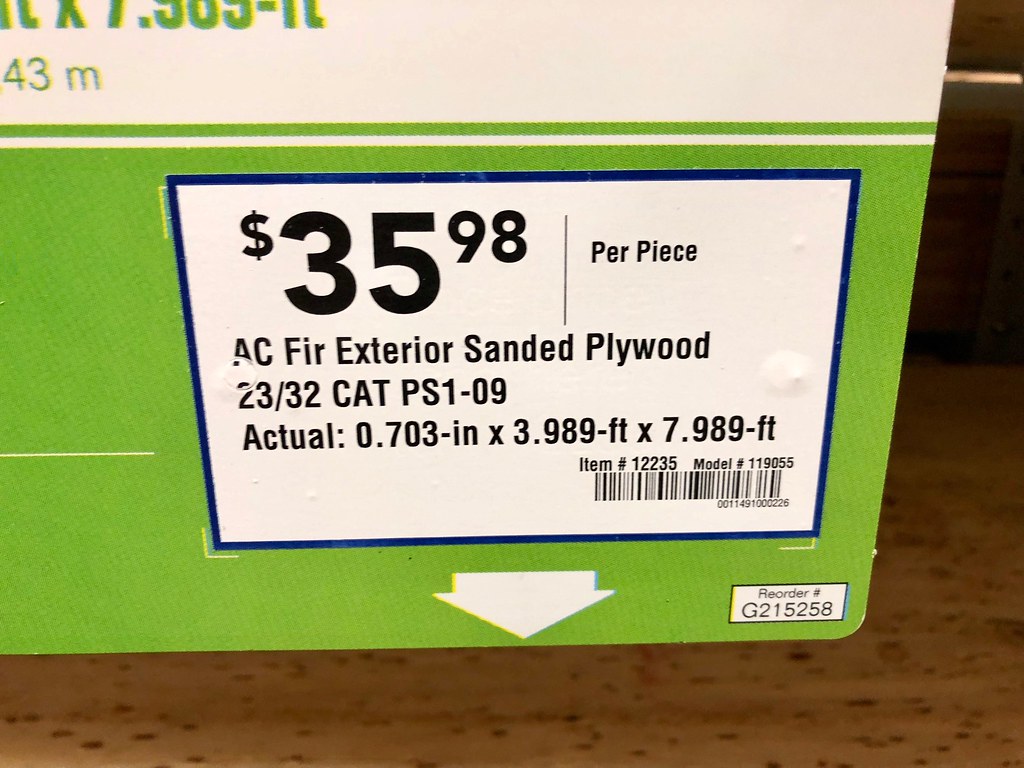

A layer of this on the bottom

Flooring

Flooring by

Petrolburner, on Flickr

I'll paint all the sides and edges with a gallon of Sherwin Williams Weather Shield paint.**

Untitled

Untitled by

Petrolburner, on Flickr

Then I have to go to Home Depot to get 4 sheets of Owen Corning Foamular rigid insulation. I'll do an inch of that stuff. It's got a pretty high density so it won't compress under the next layer...

Flooring

Flooring by

Petrolburner, on Flickr

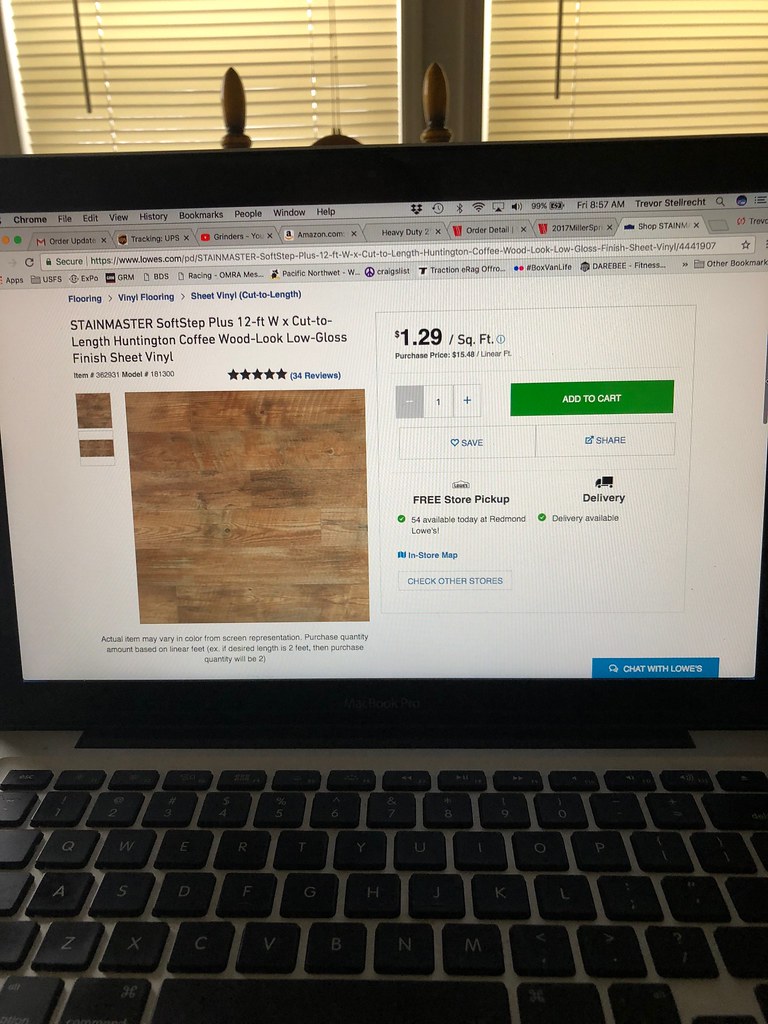

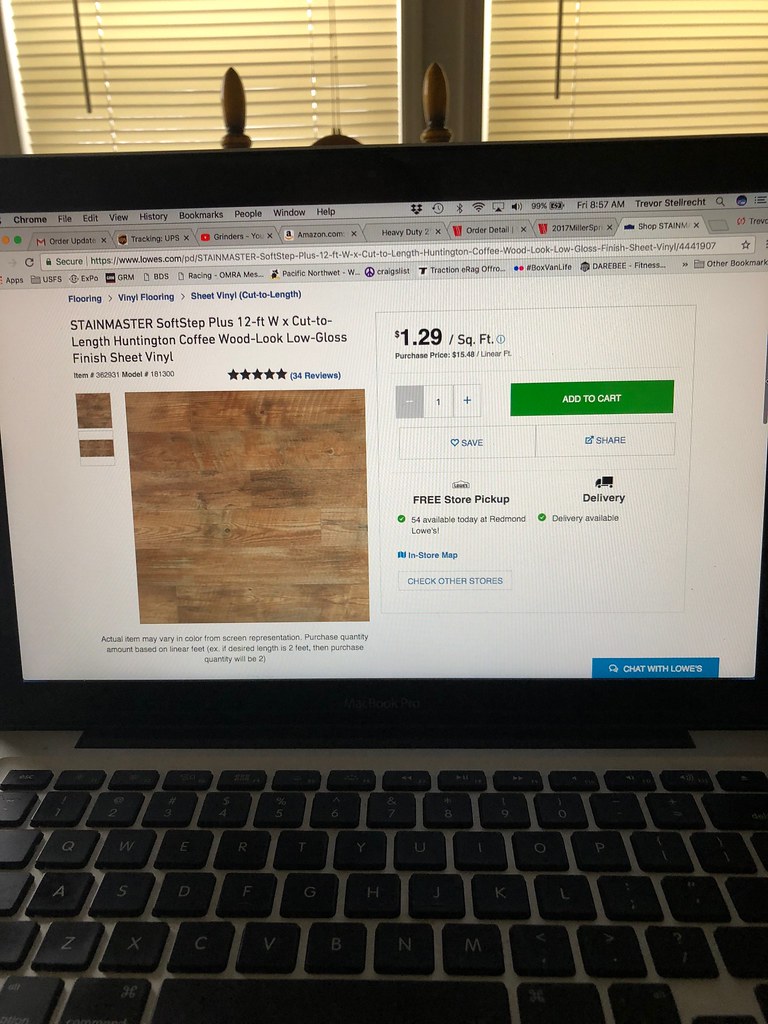

Then on top, one big sheet of wood looking vinyl

Flooring

Flooring by

Petrolburner, on Flickr

Flooring

Flooring by

Petrolburner, on Flickr

That should be plenty stiff to compensate for the 2 foot spread between the beams. I can alternate where the seams are bewteen the 3 layers of 4x8 sheets since the box is 8' wide. This way there won't be seams lined up on seams. I'll use bedliner in the wheel wells to protect from gravel and stuff. It's not so thick that I can't drill through it and run bolts through if I need to. I'll use the flush mount wheel chocks for bikes, and then a bunch of flush mount L-track for tie downs. The top sheet of plywood will be fine for anchoring the cabinets and stuff into. I hope the vinyl flooring isn't too slippery when wet, it had the best texture of all the wood look vinyl.